Screw propelling type high-pressure solid-liquid separation machine

A solid-liquid separator and screw propulsion technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large equipment loss, high energy consumption, large machine energy consumption, etc., and achieve convenient disassembly and maintenance, simple processing technology, and dehydration. Smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

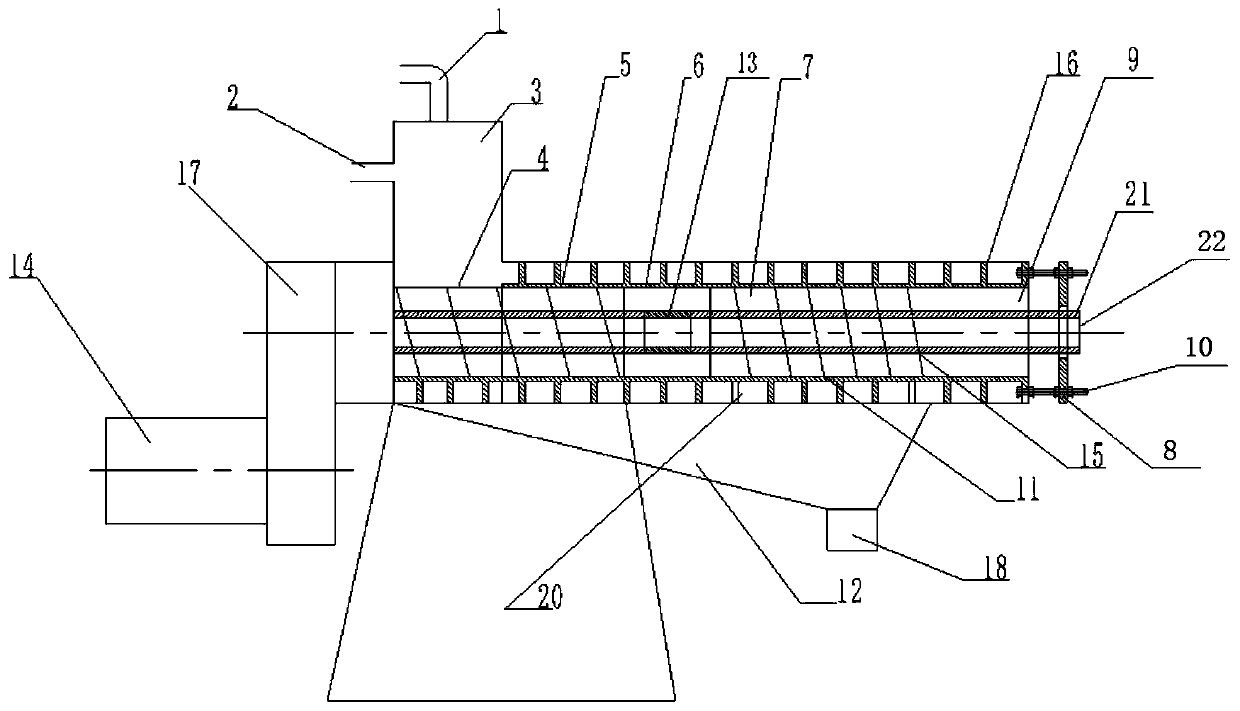

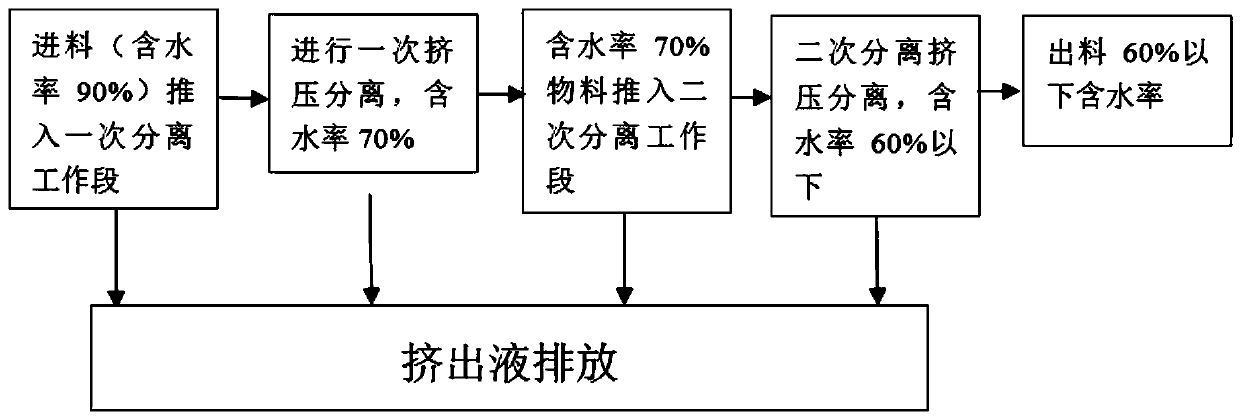

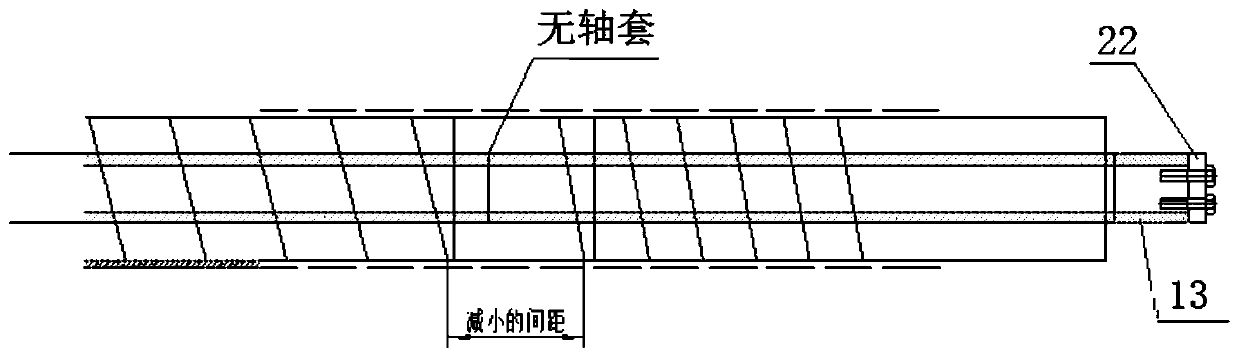

[0030] Specific implementation mode one: see Figure 1-Figure 5 This embodiment will be described. The screw propulsion high-pressure solid-liquid separator described in this embodiment includes a feed port 1, an overflow port 2, a buffer chamber 3, a retardation baffle 8, an adjusting screw 10, a screen 11, a liquid collection tank 12, and a driving device , screw extrusion propulsion rod 15, protective cover 16, drain port 18, screen reinforcement frame 20, front clamping structure 22 and some replaceable joint bushings 13; Propelling rod 15, described screw extruding propelling rod 15 periphery is equipped with screen 11, and described screen 11 is fixedly connected with protective cover 16 through screen reinforcement frame 20, and one end of described protective cover 16 is provided with driving device, drives The screw extrusion propulsion rod 15 rotates, and the other end is provided with a discharge port, and the front end of the discharge port is fixed with a blockin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com