Aircraft wing trailing edge composite bulkhead structure and manufacturing method thereof

A composite material and manufacturing method technology, applied in the direction of wings, aircraft parts, weight reduction, etc., can solve the problems of increasing the production cost of the bulkhead, poor fatigue performance, easy cracking, etc., and achieve improved structural efficiency, service life, and stability Good, the effect of reducing weight and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

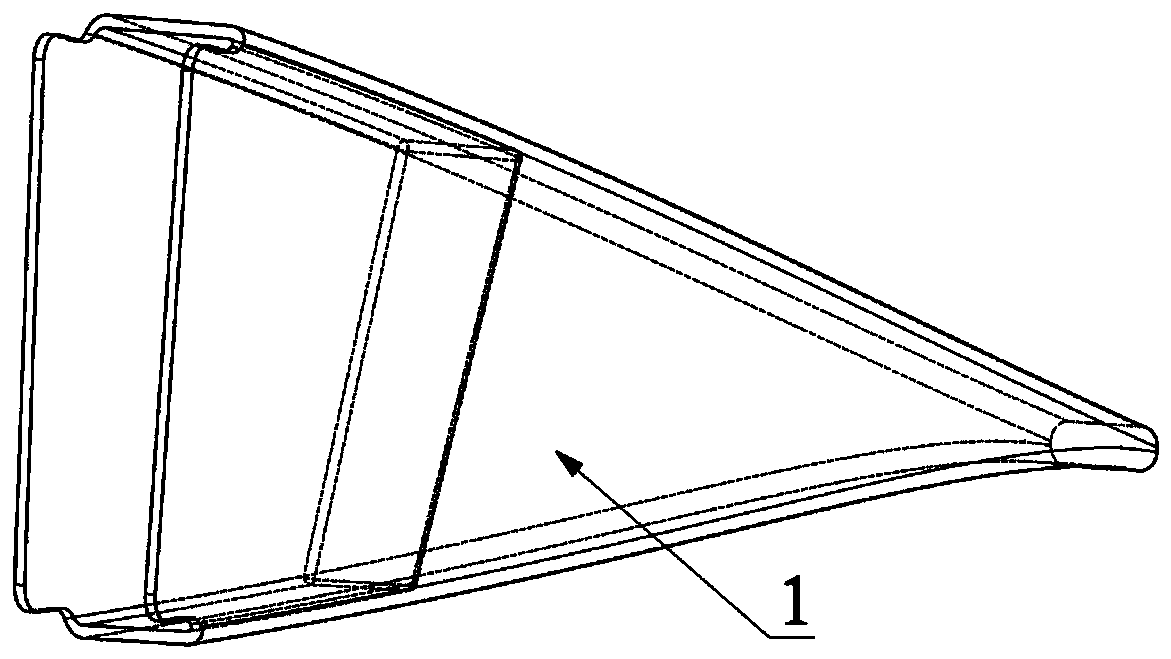

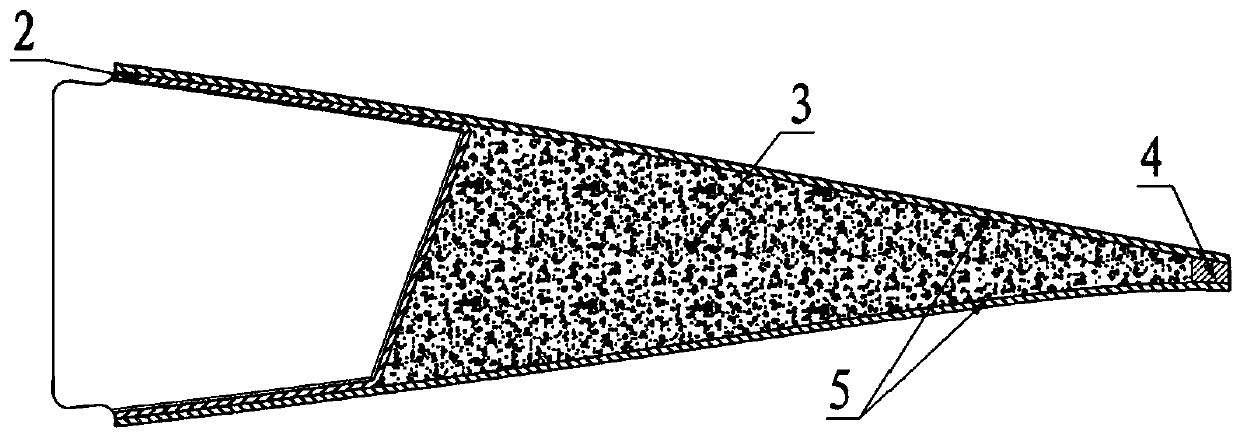

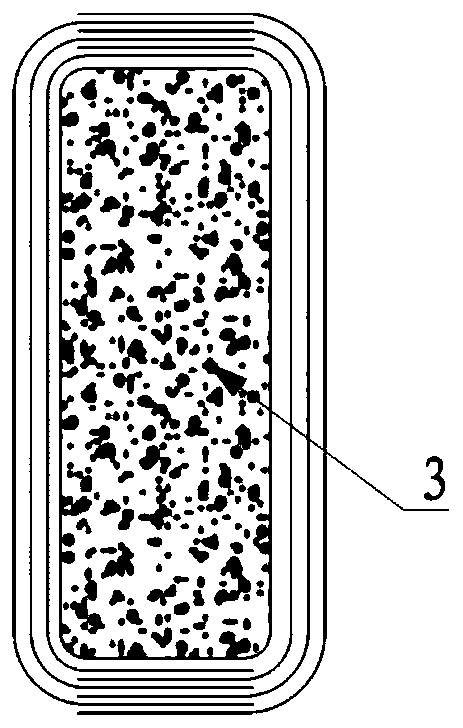

[0019] See attached picture, such as Figure 1 to Figure 4 As shown, the aircraft wing trailing edge composite bulkhead structure provided by the application, the front end of the bulkhead structure 1 is connected to the wing box section, and the two sides of the bulkhead structure 1 are connected with the movable wing surface 10 and the movable wing surface 12. Adjacent, the frame structure 1 is a wedge-shaped cantilever structure integrally formed of composite materials. Its front end has an open cavity, and its two sides are parallel to the movable wing surface. The frame structure 1 includes an outer panel 5 and a frame core. , the outer panel 5 covers the bulkhead core to form an integrated structure, the upper and lower surfaces of the outer panel 5 are the theoretical shape of the wing, the bulkhead core contains the inner panel 2 and the foam core 3, and the inner panel 2 is located in the bulkhead The inner side of the front section of structure 1 is a trapezoidal fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com