A kind of preparation method of neoprene latex for engineering waterproofing

A neoprene latex and engineering technology, which is applied in the field of preparation of neoprene latex for engineering waterproofing, can solve the problems of poor adsorption and inapplicability of anionic latex, and achieve high stability and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

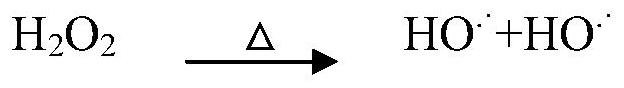

Method used

Image

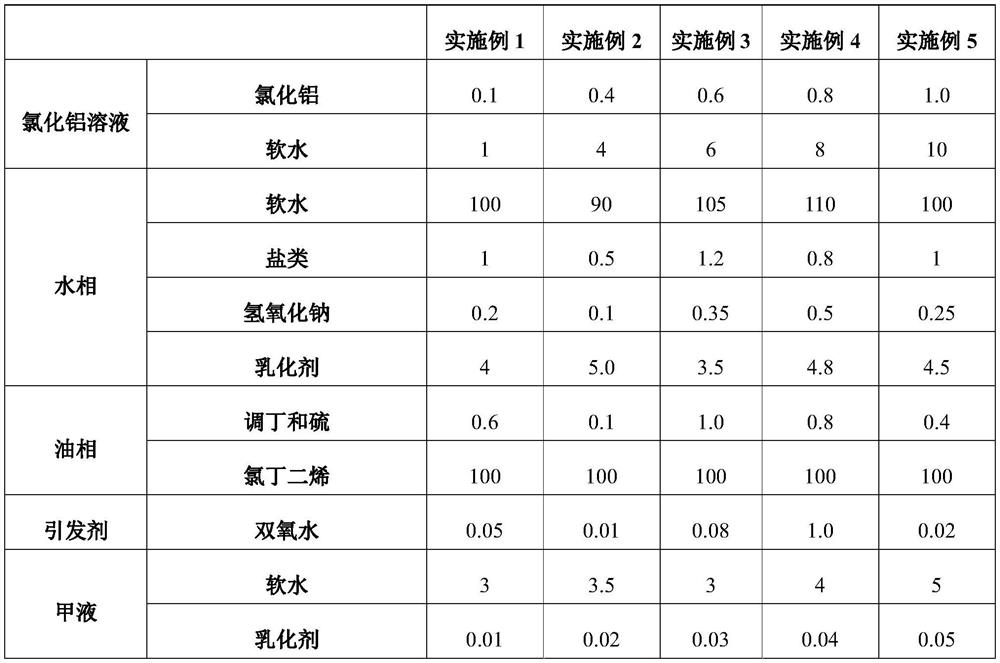

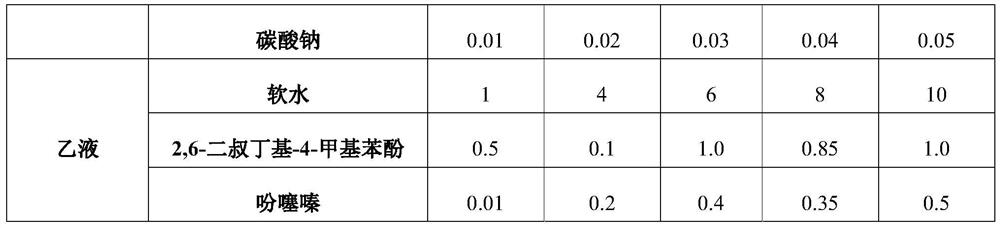

Examples

Embodiment 1

[0039] Taking preparation example 1 as example, the preparation method of neoprene latex is described in detail, a kind of preparation method of engineering waterproof neoprene latex, comprises the following steps:

[0040] Step 1 prepares aluminum chloride solution:

[0041] Add the weighed aluminum chloride (i.e. aluminum trichloride) into the preparation barrel, slowly add soft water (without calcium, magnesium and other ions) under continuous stirring, so that the aluminum chloride is completely dissolved, cool to normal temperature, and set aside.

[0042] Step 2 Prepare the water phase:

[0043] After the soft water has been measured in the water phase preparation tank, the weighed sodium hydroxide, salts and dodecyltrimethylammonium chloride are added successively under stirring to obtain the water phase, and the prepared aluminum chloride solution Pour it into the water phase liquid, and at the same time use the pump to circulate, so that the substances added to the w...

Embodiment 1~4 and comparative example 1

[0066] Carry out experimental detection to above-mentioned embodiment 1~4 and comparative example 1~3:

[0067] 1. Stability testing

[0068] According to the measurement standard SH / T 1151-1992 (confirmed in 1998) for the high-speed mechanical stability of synthetic latex, the amount of gel produced under high-speed stirring is detected to examine the stability of chloroprene latex. The test results are shown in Table 2 below:

[0069] Table 2 is the stability of embodiment 1~4 and comparative example 1~3 chloroprene latex

[0070] Numbering Example 1 Example 2 Example 3 Example 4 Comparative example 1 Comparative example 2 Comparative example 3 Gel amount none none none none trace a small amount a small amount

[0071] In conjunction with Table 2, it can be seen that the neoprene latex obtained in Examples 1 to 4 does not have gel during the experiment, that is, the stability is good, and the adhesive will not be affected by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com