Preparation method of anti-yellowing halogen-free flame retardant applied to LED lampshades

An LED lampshade and anti-yellowing technology, which is applied in the field of flame retardant processing, can solve problems such as the yellowing resistance of LED lampshades that affect the flame retardant effect of flame retardants, and improve the flame retardant performance and yellowing resistance. Simple, the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

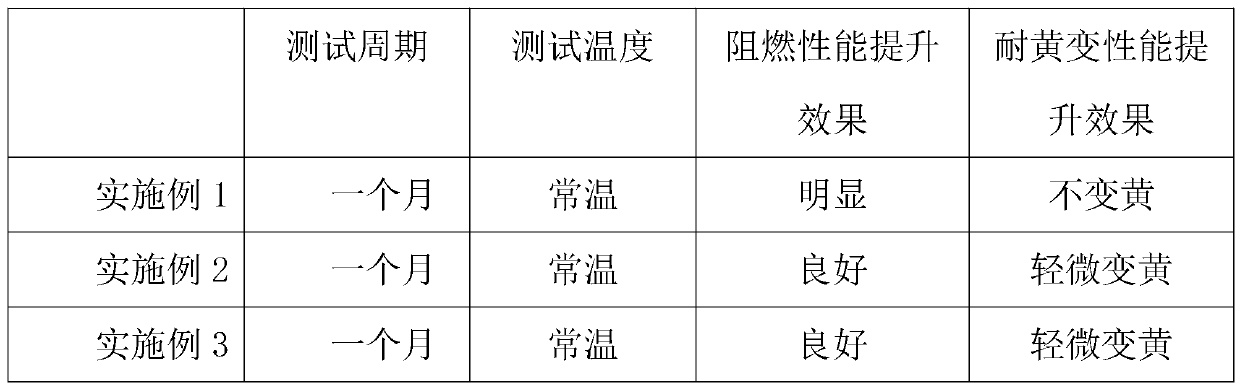

Embodiment 1

[0022] A non-yellowing non-halogen flame retardant applied to LED lampshades, comprising the following components: aluminum hydroxide particles, compatibilizer, ammonium polyphosphate powder, tricumyl phosphate, dolomite powder, clay, benzene peroxide formyl, anti-yellowing agent and deionized water;

[0023] Specifically in this embodiment, the following components by weight are included: 65 parts of aluminum hydroxide particles, 15 parts of compatibilizer, 15 parts of ammonium polyphosphate powder, 7 parts of tricumyl phosphate, 15 parts of dolomite powder, clay 30 parts, 3 parts of benzoyl peroxide, 15 parts of anti-yellowing agent and 80 parts of deionized water.

[0024] Further, among the above-mentioned ingredients, the mesh numbers of aluminum hydroxide particles, ammonium polyphosphate powder, and dolomite powder are all 200 mesh, and the compatibilizer adopts maleic anhydride graft compatibilizer or other materials with the ability to combine the two polymers Togeth...

Embodiment 2

[0031] A non-yellowing non-halogen flame retardant applied to LED lampshades, comprising the following components: aluminum hydroxide particles, compatibilizer, ammonium polyphosphate powder, tricumyl phosphate, dolomite powder, clay, benzene peroxide formyl, anti-yellowing agent and deionized water;

[0032] Specifically in this embodiment, the following components by weight are included: 60 parts of aluminum hydroxide particles, 12 parts of compatibilizer, 12 parts of ammonium polyphosphate powder, 6 parts of tricumyl phosphate, 12 parts of dolomite powder, clay 25 parts, benzoyl peroxide 2 parts, anti-yellowing agent 12 parts and deionized water 70 parts.

[0033] Further, among the above-mentioned ingredients, the mesh numbers of aluminum hydroxide particles, ammonium polyphosphate powder, and dolomite powder are all 200 mesh, and the compatibilizer adopts maleic anhydride graft compatibilizer or other materials with the ability to combine the two polymers Together polyme...

Embodiment 3

[0040] A non-yellowing non-halogen flame retardant applied to LED lampshades, comprising the following components: aluminum hydroxide particles, compatibilizer, ammonium polyphosphate powder, tricumyl phosphate, dolomite powder, clay, benzene peroxide formyl, anti-yellowing agent and deionized water;

[0041] Specifically in this embodiment, the following components by weight are included: 70 parts of aluminum hydroxide particles, 18 parts of compatibilizer, 18 parts of ammonium polyphosphate powder, 8 parts of tricumyl phosphate, 18 parts of dolomite powder, clay 35 parts, 4 parts of benzoyl peroxide, 18 parts of anti-yellowing agent and 90 parts of deionized water.

[0042] Further, among the above-mentioned ingredients, the mesh numbers of aluminum hydroxide particles, ammonium polyphosphate powder, and dolomite powder are all 100 mesh, and the compatibilizer adopts maleic anhydride graft compatibilizer or other materials capable of combining the two polymers Together poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com