Organic composite phase change energy storage material and preparation method and application thereof

A technology of composite phase change and energy storage materials, applied in the field of organic composite phase change energy storage materials and their preparation, can solve the problems of high requirements for thermal insulation measures, difficult long-term storage of heat, etc. Simple, long recovery half-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

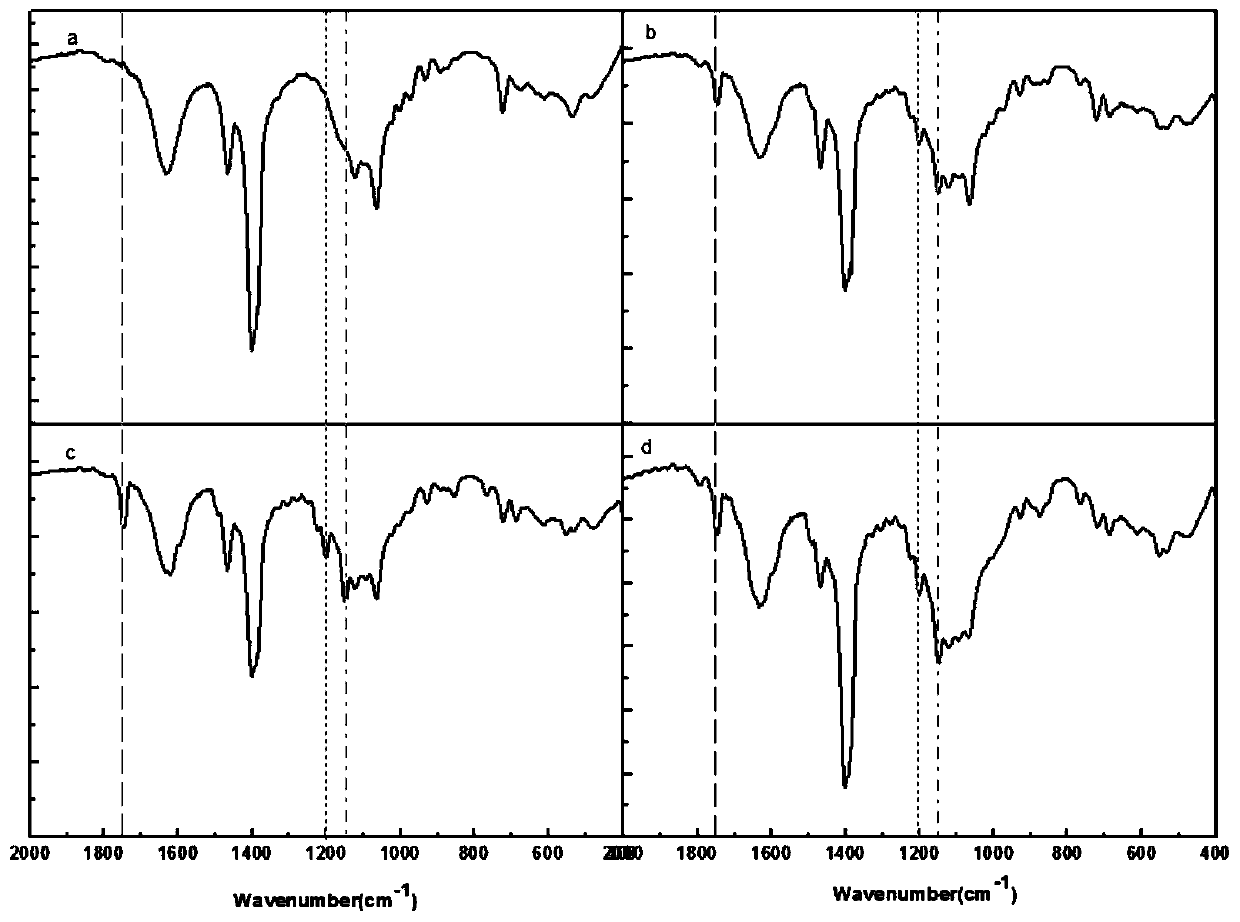

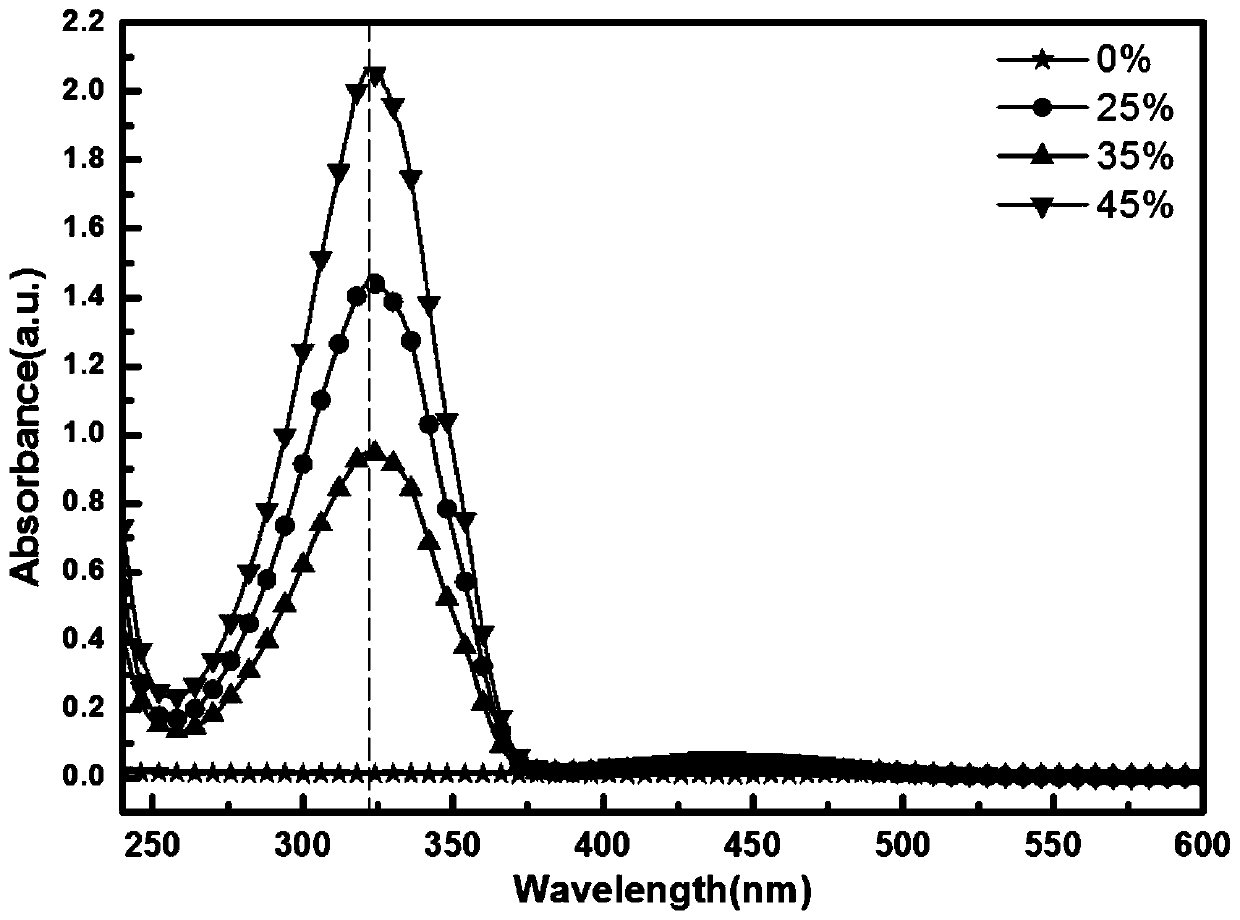

Embodiment 1

[0039] Preparation of azobenzene compound: myristate chloride is reacted to generate tetradecanoic acid chloride, tetradecanoic acid chloride is esterified with 4-(phenylazo)phenol, suction filtered and washed to obtain myristate azobenzene .

[0040] Mix 0.25 g of myristate azobenzene and 0.75 g of myristyl alcohol to obtain a mixture, add 5 mL of dichloromethane to the mixture to completely dissolve, nitrogen purging and vacuum drying at room temperature to obtain an organic composite phase change energy storage material.

Embodiment 2

[0042] Preparation of azobenzene compound: myristate chloride is reacted to generate tetradecanoic acid chloride, tetradecanoic acid chloride is esterified with 4-(phenylazo)phenol, suction filtered and washed to obtain myristate azobenzene .

[0043] Mix 0.35 g of myristate azobenzene and 0.65 g of myristyl alcohol to obtain a mixture, add 5 mL of dichloromethane to the mixture to completely dissolve, nitrogen purging and vacuum drying at room temperature to obtain an organic composite phase change energy storage material.

Embodiment 3

[0045] Preparation of azobenzene compound: myristate chloride is reacted to generate tetradecanoic acid chloride, tetradecanoic acid chloride is esterified with 4-(phenylazo)phenol, suction filtered and washed to obtain myristate azobenzene .

[0046] Mix 0.45 g of myristate azobenzene and 0.55 g of myristyl alcohol to obtain a mixture, add 5 mL of dichloromethane to the mixture to completely dissolve, nitrogen purging and vacuum drying at room temperature to obtain an organic composite phase change energy storage material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com