Environment-friendly energy-saving furnace

An environmental protection and energy-saving furnace body technology, which is applied to household furnaces/stoves, furnaces/stoves with hot water devices, heating methods, etc., can solve insufficient coal combustion, reduce heat conversion efficiency, and affect environmental quality, etc. problems, to achieve the effect of ensuring the efficiency and quality of heat transfer, improving the quality of preheating, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

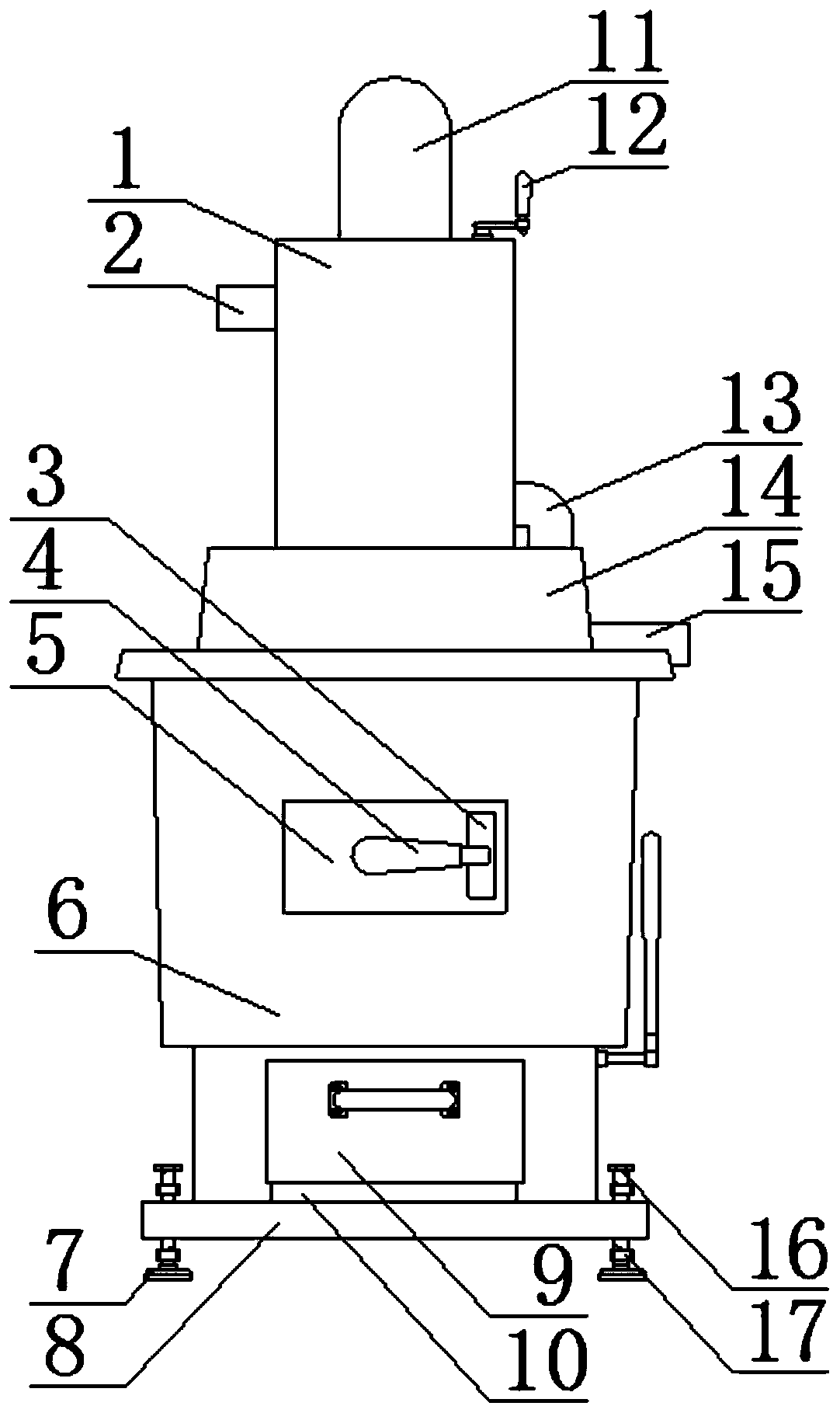

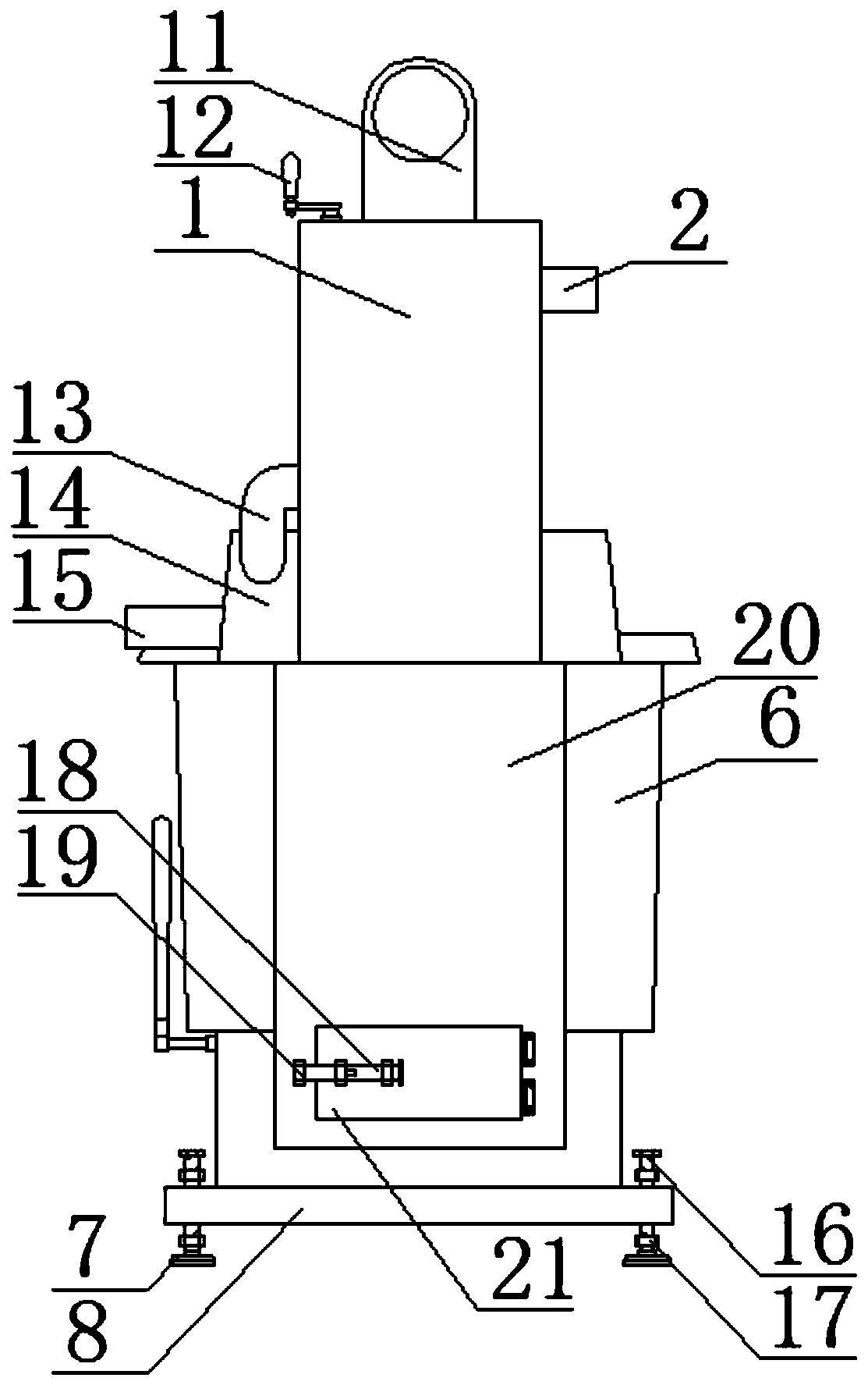

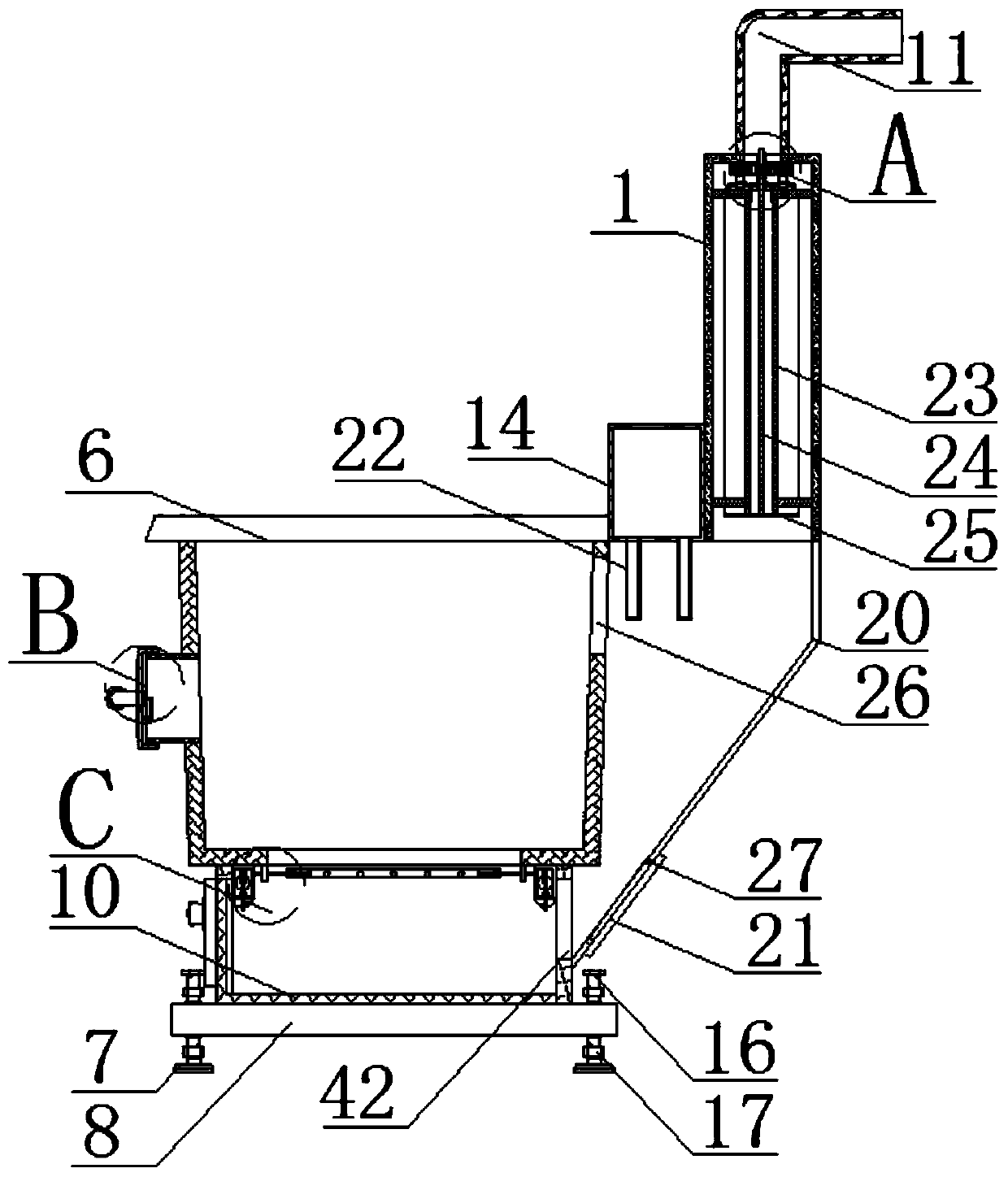

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0039] refer to Figure 1-12 , an environmentally friendly and energy-saving furnace, including a furnace body 6, the lower end of the furnace body 6 is provided with a support mechanism, which can well adapt to the ground in different situations, ensures the stability of the furnace body 6, and avoids the instability of the furnace body 6 due to uneven ground Situation takes place, avoid body of heater 6 toppling over, and support mechanism comprises the base plate 8 that is fixed on the lower end of body of heater 6, and base plate 8 is fixed on the lower end of body of heater 6 by welding, promotes the solid degree of connection.

[0040] In the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com