Boulder blasting construction method

A construction method and boulder technology, applied in blasting and other directions, can solve the problems of affecting the construction progress, poor treatment effect, large boulder particle size, etc., to increase construction safety, improve crushing effect, and increase controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

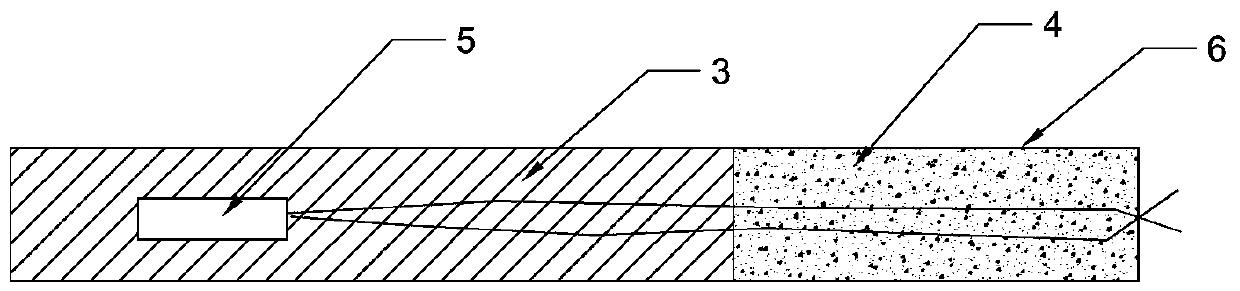

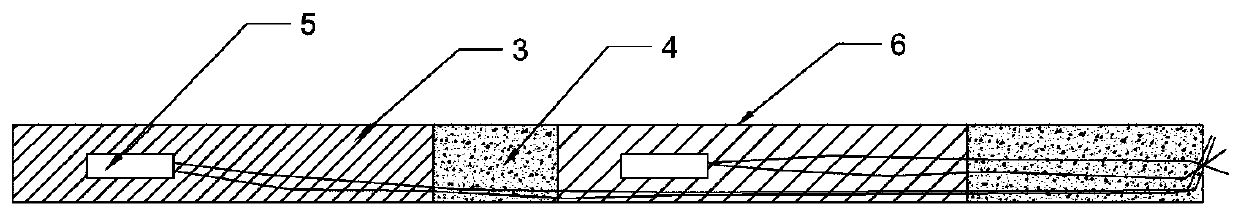

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] A construction method for boulder blasting, comprising the following steps:

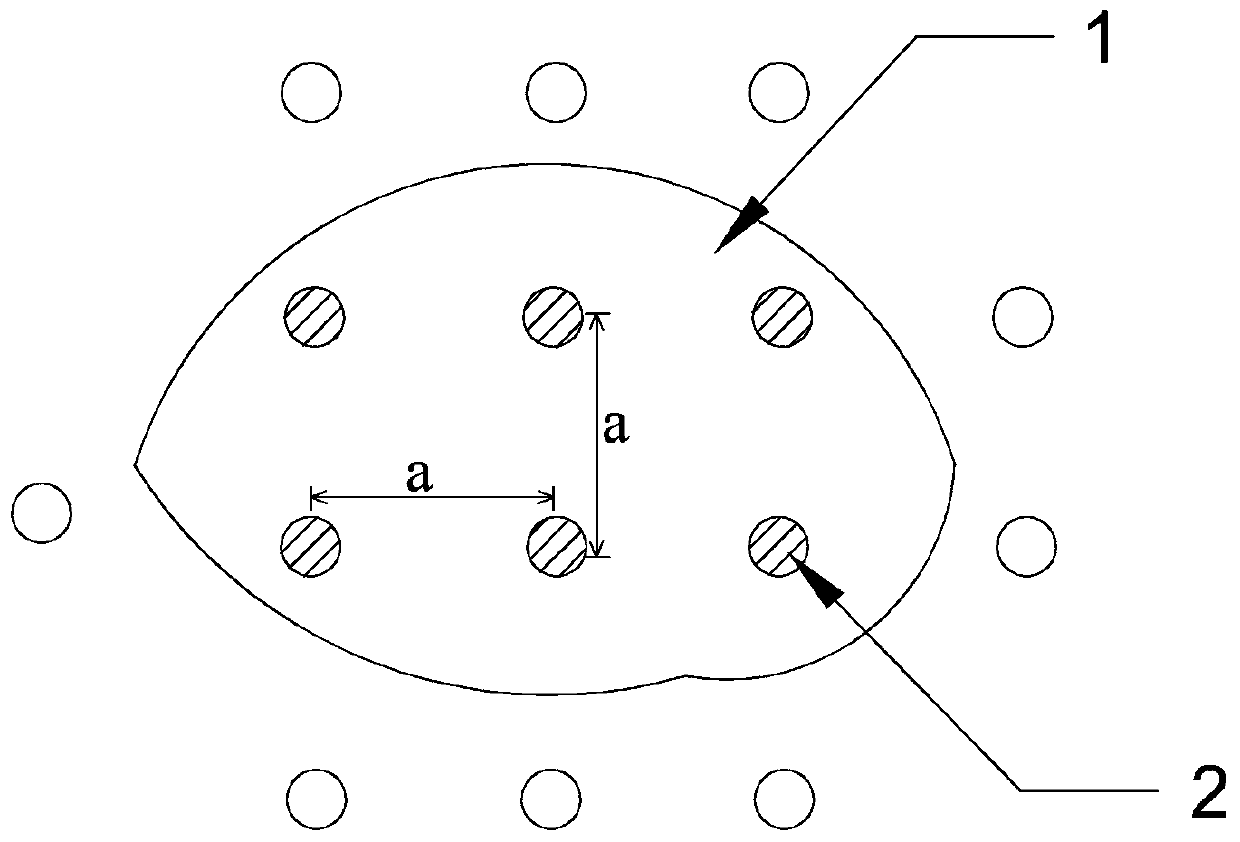

[0040] (1) The 2-bit setting of the blast hole: such as figure 1 As mentioned above, the arrangement range of the blast hole 2 is larger than the scope of the boulder 1, and the charge bag is installed in the blast hole 2 located on the boulder 1, and no charge is installed in the blast hole 2 outside the range of the boulder 1. Bag.

[0041] Boulder 1 blasting is divided into single-hole single blasting and multi-hole single blasting. The 2-position blast hole for single-hole single-body blasting is set at the center of gravity of boulder 1, and the 2-position blast hole for multi-hole single-body blasting adopts plum blossoms. Shaped or rectangular, the distance between adjacent blast holes 2 in the porous single blasting is 0.8-1.2m, and the diameter of blast holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com