Fingerstall with sterile pressing function

A technology of finger cots and pressing parts, which is applied in the field of medical devices, can solve problems such as inadequate pressing of puncture points, infection of puncture points, poor blood supply of fingers, etc., to avoid skin necrosis, bruising, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

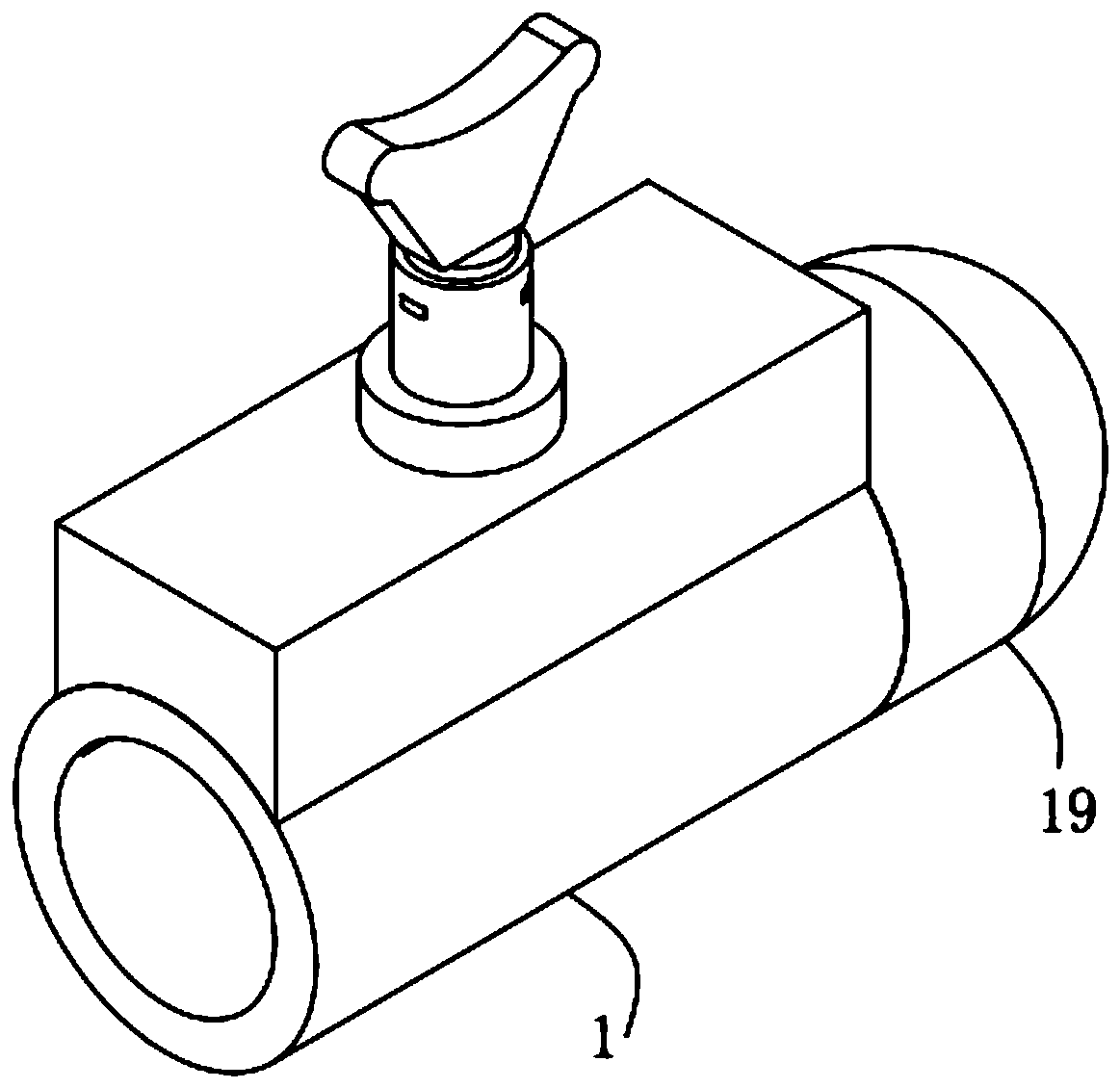

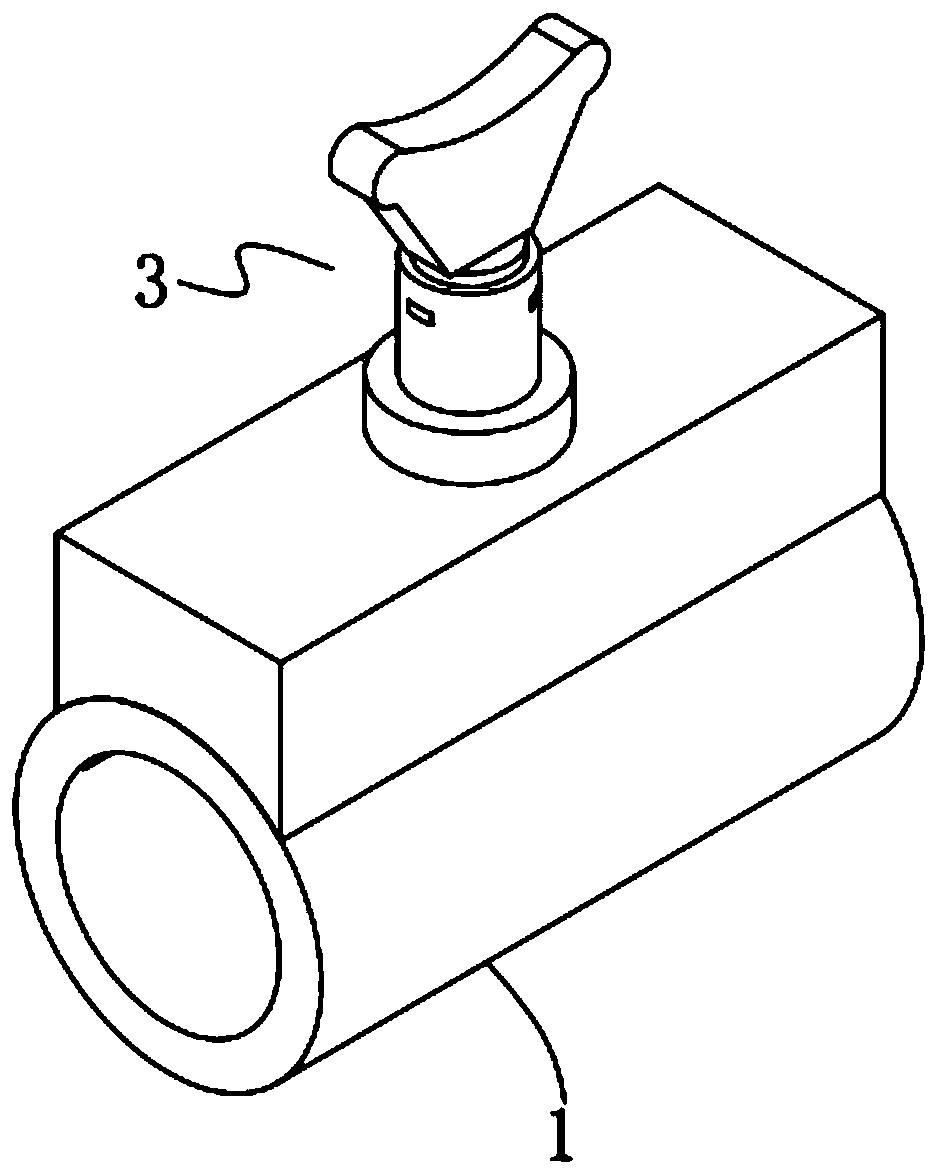

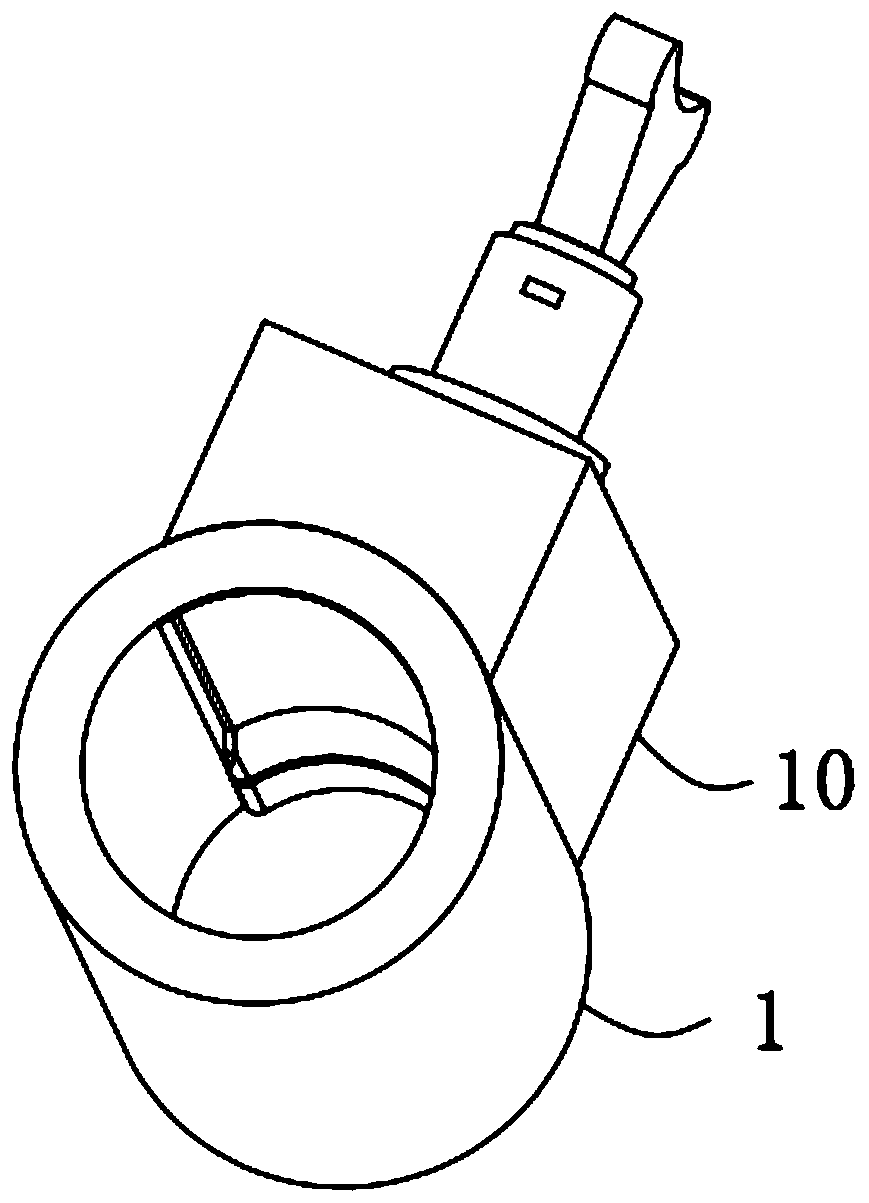

[0048] A finger cot with sterile compression such as Figure 1-2 And as shown in 6-8, it includes a sleeve 1, a pressing unit 2, an adjustment unit 3 and a sterile protection unit 4. Both ends of the sleeve 1 are open structures, and the side wall of the sleeve 1 is provided with There is a through groove 5, the pressing unit 2 is movably installed inside the through groove 5, the adjusting unit 3 is fixedly installed on the outer side wall of the sleeve 1, and the adjusting unit 3 and the pressing unit 2 in transmission connection, the sterile protection unit 4 is fixedly installed at one end of the sleeve 1.

[0049] By adopting the above-mentioned technical scheme, the sleeve 1 is used as the structural main body of the finger cot, and at the same time, it is used to cover the patient's punctured finger; the pressing unit 2 can not only fix the finger cot on the patient's punctured finger, but also The puncture point on the finger is pressed; the adjusting unit 3 is used t...

Embodiment 2

[0077] The difference from Example 1 lies in the preparation of the arc-shaped silicone gasket 6, and its specific preparation method is as follows:

[0078] Take the following raw materials and weigh them by weight: 75 parts of methyl vinyl phenyl silicone rubber, 14 parts of polyurethane, 11 parts of zinc oxide powder, 25 parts of nano-silver powder, 11 parts of calcium carbonate powder, 3 parts of p-phenylenediamine 3 parts, 3 parts of diethylthiourea, 3 parts of paraffin oil, 3 parts of tricresyl phosphate;

[0079] S1. Put the weighed methyl vinyl phenyl silicone rubber and polyurethane into the pulverizer for pulverization, set the speed of the pulverizer to 600r / min, and keep the particle diameter of the pulverized mixed material at 7mm, In this way, a pulverized mixed material is obtained;

[0080] S2. Put the pulverized mixed material prepared in step S1 into an internal mixer for internal mixing, set the temperature of the internal mixer to 140° C., the rotational s...

Embodiment 3

[0086] The difference from Example 1 lies in the preparation of the arc-shaped silicone gasket 6, and its specific preparation method is as follows:

[0087] Take the following raw materials and weigh them by weight: 80 parts of methyl vinyl phenyl silicone rubber, 16 parts of polyurethane, 12 parts of zinc oxide powder, 30 parts of nano-silver powder, 12 parts of calcium carbonate powder, 4 parts of p-phenylenediamine 4 parts, 4 parts of diethylthiourea, 4 parts of paraffin oil, 4 parts of tricresyl phosphate;

[0088] S1. Put the weighed methyl vinyl phenyl silicone rubber and polyurethane into the pulverizer for pulverization, set the speed of the pulverizer to 700r / min, and keep the particle diameter of the pulverized mixed material at 8mm, In this way, a pulverized mixed material is obtained;

[0089] S2. Put the pulverized mixed material prepared in step S1 into the internal mixer for internal mixing, set the temperature of the internal mixer to 150°C, the speed to 800r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com