Human fibrin in-vitro degradation method

A technology for fibrin and degradation products, applied in the field of in vitro degradation of human fibrin, can solve the problems of FDP and D-dimer purity and stability, complex methods, and inability to be used as quality control or standard products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

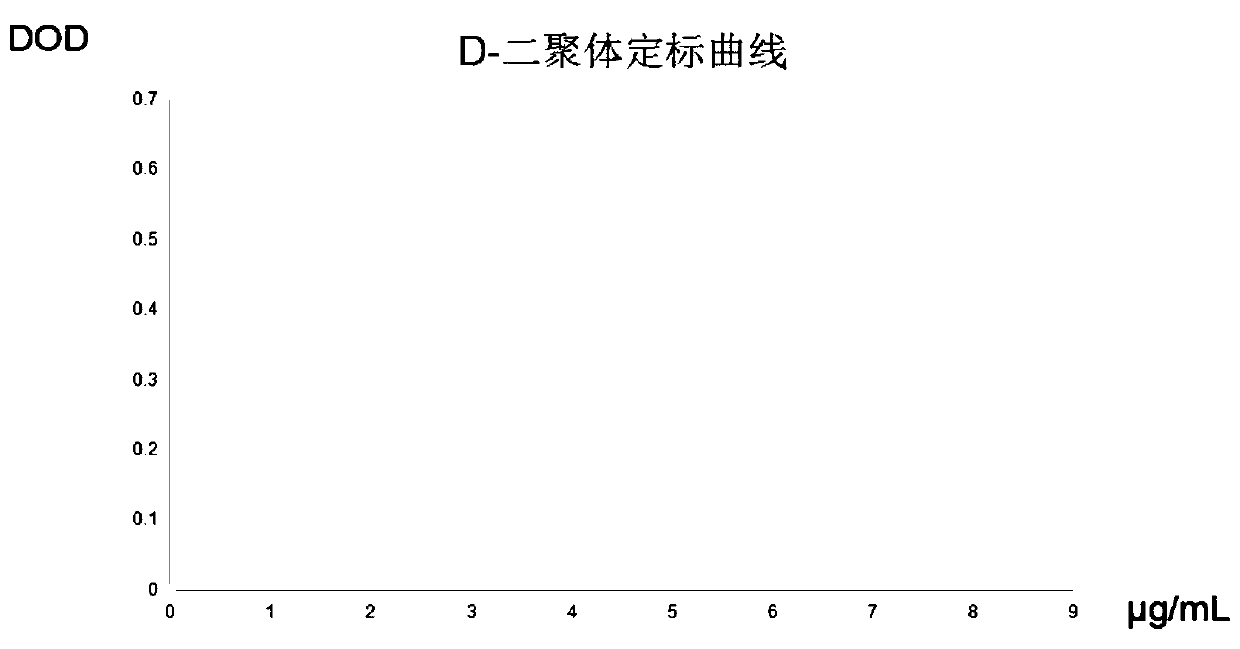

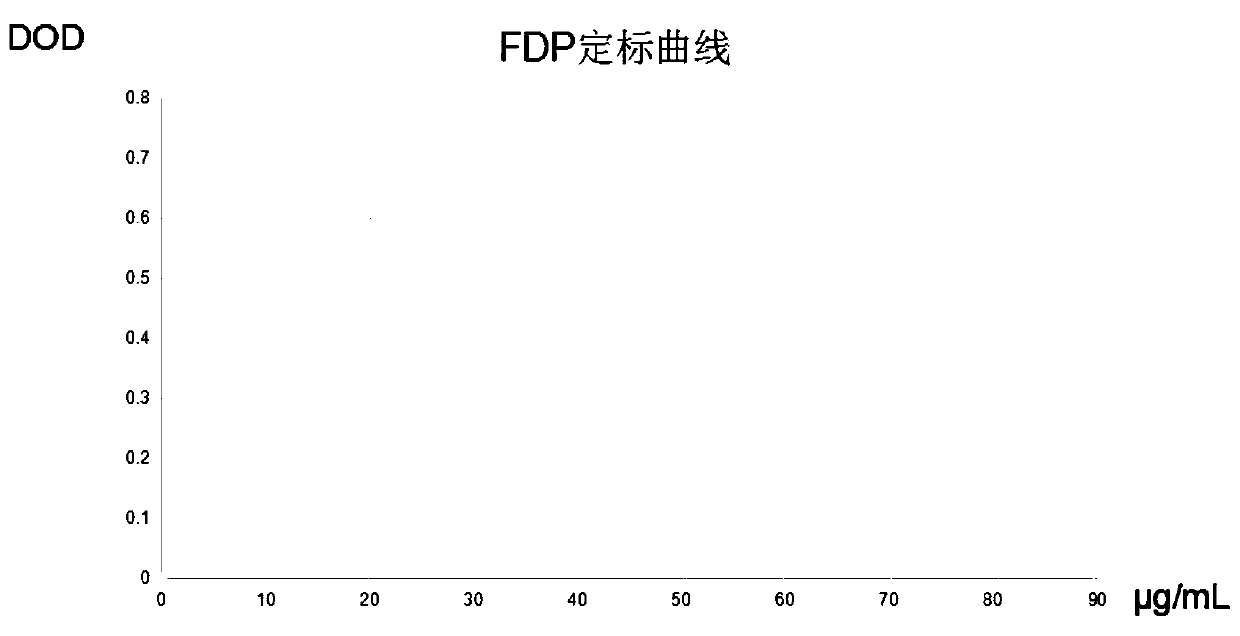

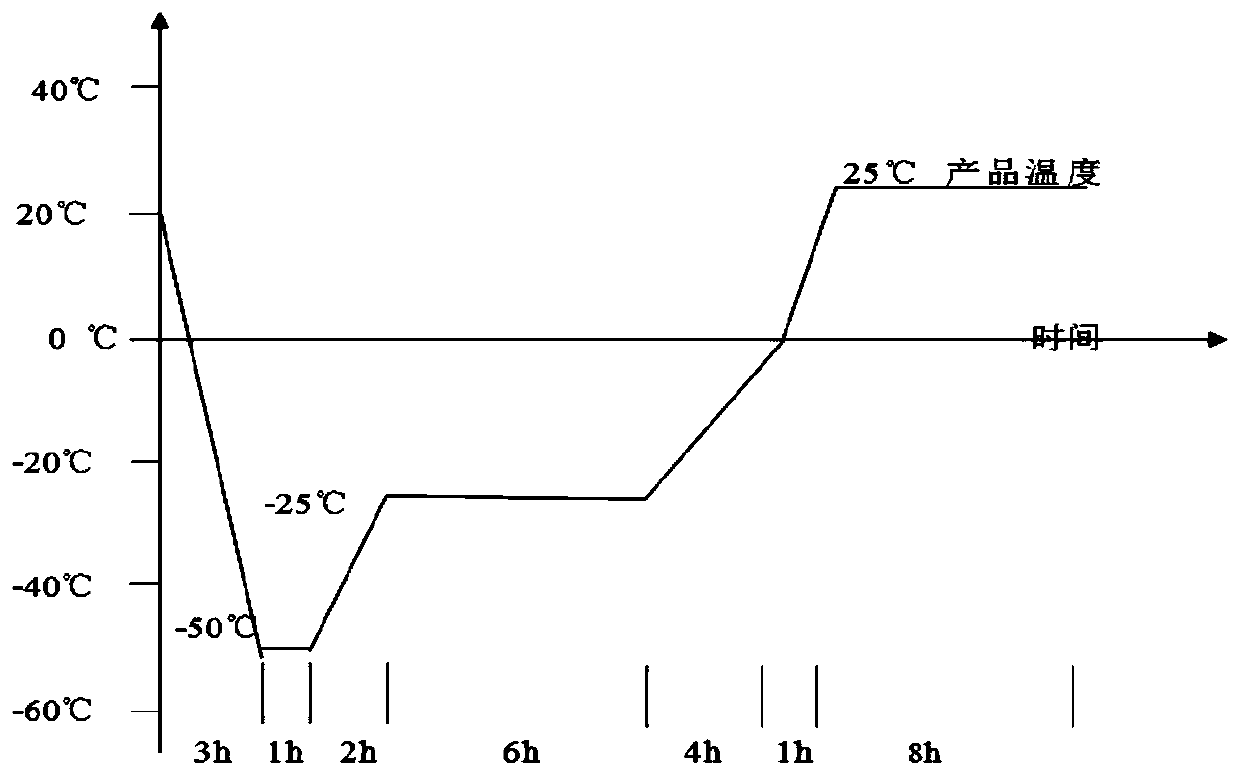

Image

Examples

Embodiment 1

[0039] Embodiment 1 preparation process screening

[0040] 1. Raw material preparation and preparation

[0041] 1.1. Tris (Tris) sodium chloride degradation buffer: 50 mM Tris-HCl, 0.9% normal saline, 0.1% sodium benzoate, pH 8.5.

[0042] 1.2, 2× freeze-drying buffer: 4-hydroxyethylpiperazineethanesulfonic acid (Hepes) 4%, trehalose 1g / L, bovine albumin 70g / L, mannitol 40g / L, sodium benzoate 0.2wt%, pH 7.6-7.8;

[0043] 1 × lyophilization buffer: 4-hydroxyethylpiperazineethanesulfonic acid (Hepes) 2%, trehalose 0.5g / L, bovine albumin 35g / L, mannitol 20g / L, sodium benzoate 0.1wt%, pH 7.6-7.8;

[0044] 1.3, calcium chloride (CaCl 2 ) solution: 25mM CaCl 2 solution.

[0045] 1.4. Fibrinolytic enzyme: Fibrinolytic enzyme purchased from Sigma, reconstituted in pure water, frozen in aliquots and stored in a -20°C refrigerator.

[0046] 1.5. Thrombin: dissolved in normal saline to prepare 120U / ml. Add thrombin to a final concentration of 2-3U / mL each time.

[0047] 1.6, pla...

Embodiment 2

[0084] According to the result of embodiment 1, select following steps to degrade:

[0085] 1. Raw material preparation and preparation

[0086] 1.1 Tris (Tris) sodium chloride degradation buffer: 50 mM Tris-HCl, 0.9% normal saline, 0.1% sodium benzoate, pH 8.5.

[0087] 1.2 2× freeze-drying buffer: 4-hydroxyethylpiperazineethanesulfonic acid (Hepes) 4%, trehalose 1g / L, bovine albumin 70g / L, mannitol 40g / L, sodium benzoate 0.2wt%, pH 7.6-7.8;

[0088] 1 × lyophilization buffer: 4-hydroxyethylpiperazineethanesulfonic acid (Hepes) 2%, trehalose 0.5g / L, bovine albumin 35g / L, mannitol 20g / L, sodium benzoate 0.1wt%, pH 7.6-7.8;

[0089] 1.3 Calcium chloride (CaCl 2 ) solution: 25mM CaCl 2 solution.

[0090] 1.4 Plasmin: Plasmin purchased from Sigma, reconstituted in pure water, frozen in aliquots and stored in a -20°C refrigerator.

[0091] 1.5 Thrombin: dissolved in normal saline to make 120U / ml. Add thrombin to a final concentration of 2-3U / mL each time.

[0092] 1.6 Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com