A kind of high-efficiency polysilicon ingot casting method

A technology of polysilicon and ingot casting, which is applied in the field of solar cells, can solve the problems of waste of raw materials, reduce the cost of feeding high-efficiency polysilicon ingots, etc., and achieve the effects of avoiding waste, reducing the cost of feeding materials, and effectively utilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate understanding of the present invention, the present invention will be described more fully described with reference to the related drawings. Several embodiments of the invention are given in the drawings. However, the present invention can be implemented in many different forms, and is not limited to the embodiments described herein. Conversely, the purpose of providing these examples is to make the disclosure of the present invention more thoroughly.

[0027] All techniques and scientific terms used herein are identical to those skilled in the art, unless otherwise defined. The terms used herein in the specification of the present invention are intended to describe specific embodiments, and is not intended to limit the invention. The terms "and / or" as used herein include any and all combinations of one or more related list items.

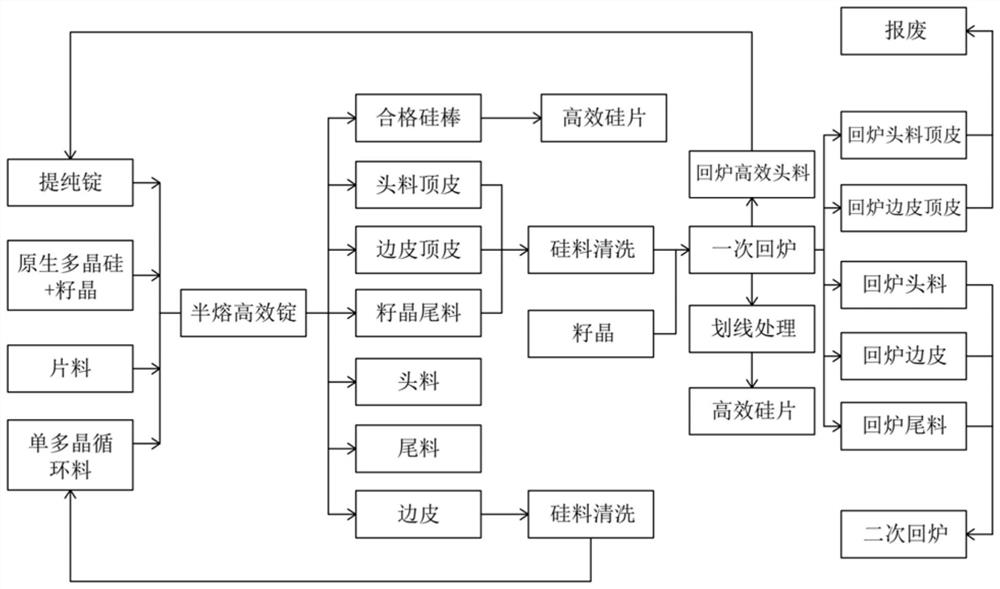

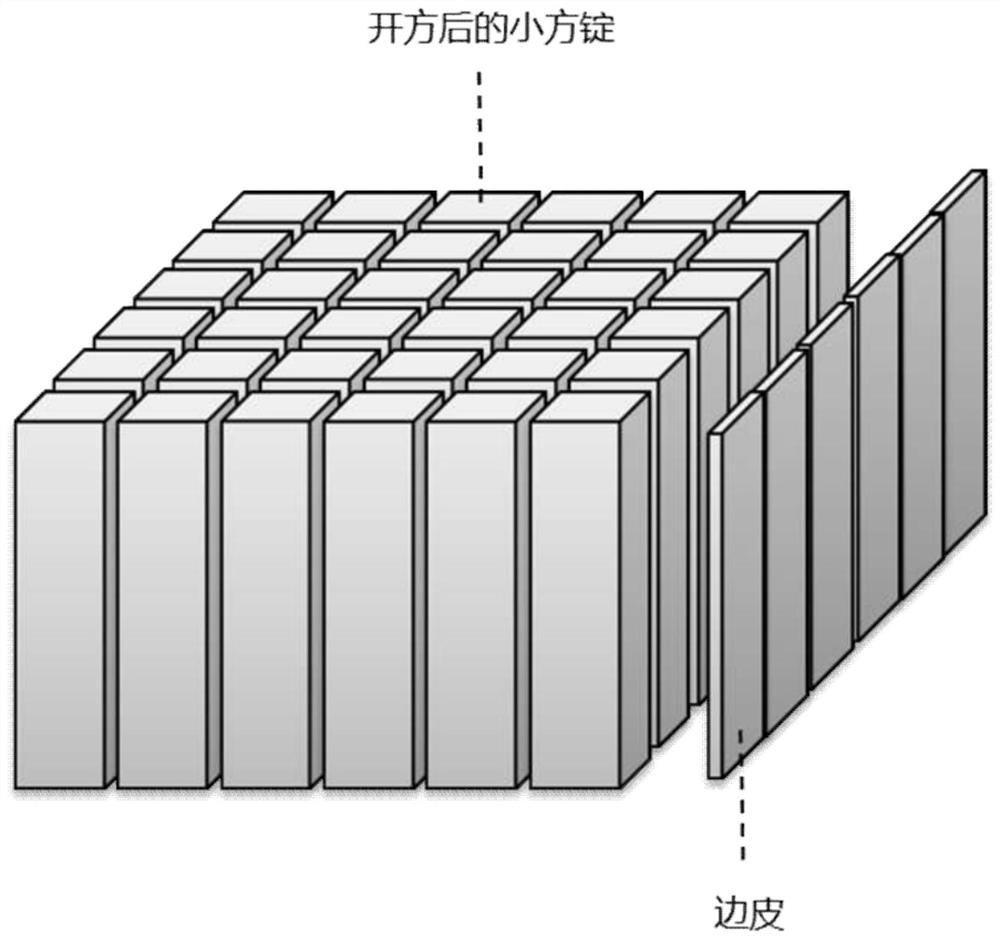

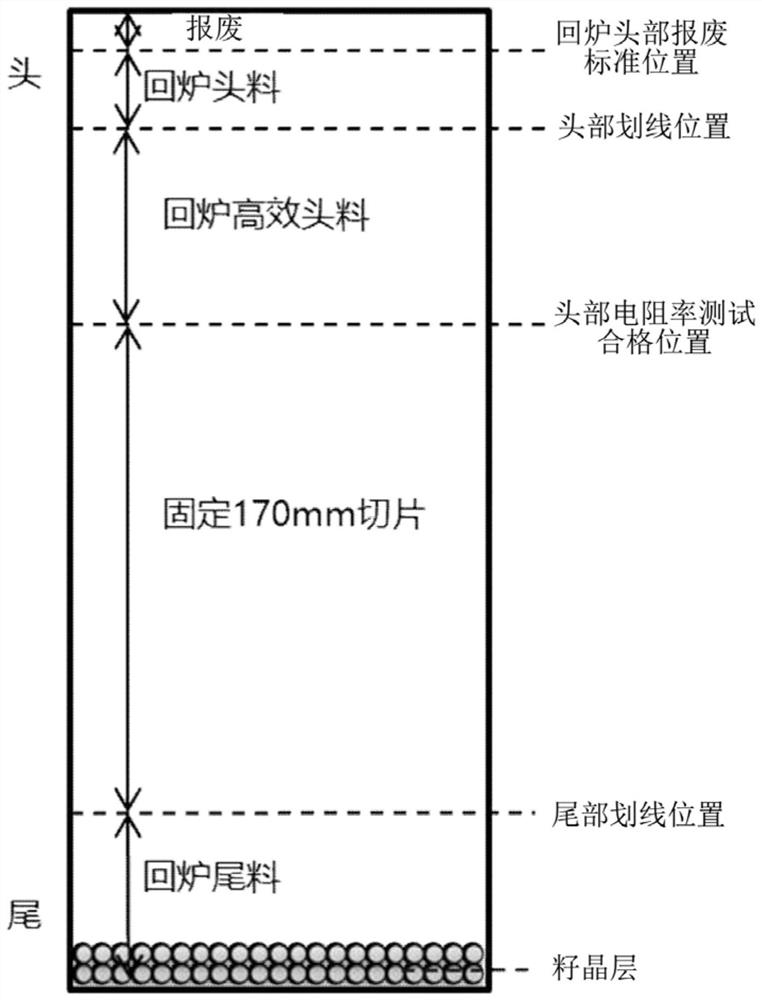

[0028] Embodiments of the present invention provide a highly efficient polycrystalline silicon ing ingot, including st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com