Anti-seismic reinforcing method for loess cave dwelling by replacing covering soil in vault sheared area

A technology for replacing soil and vaults, applied in building maintenance, building types, construction, etc., can solve the problems of loess cave dwelling safety hazards, loess cave dwelling instability, loss of stability, etc., and achieve low construction cost, less construction equipment, achieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

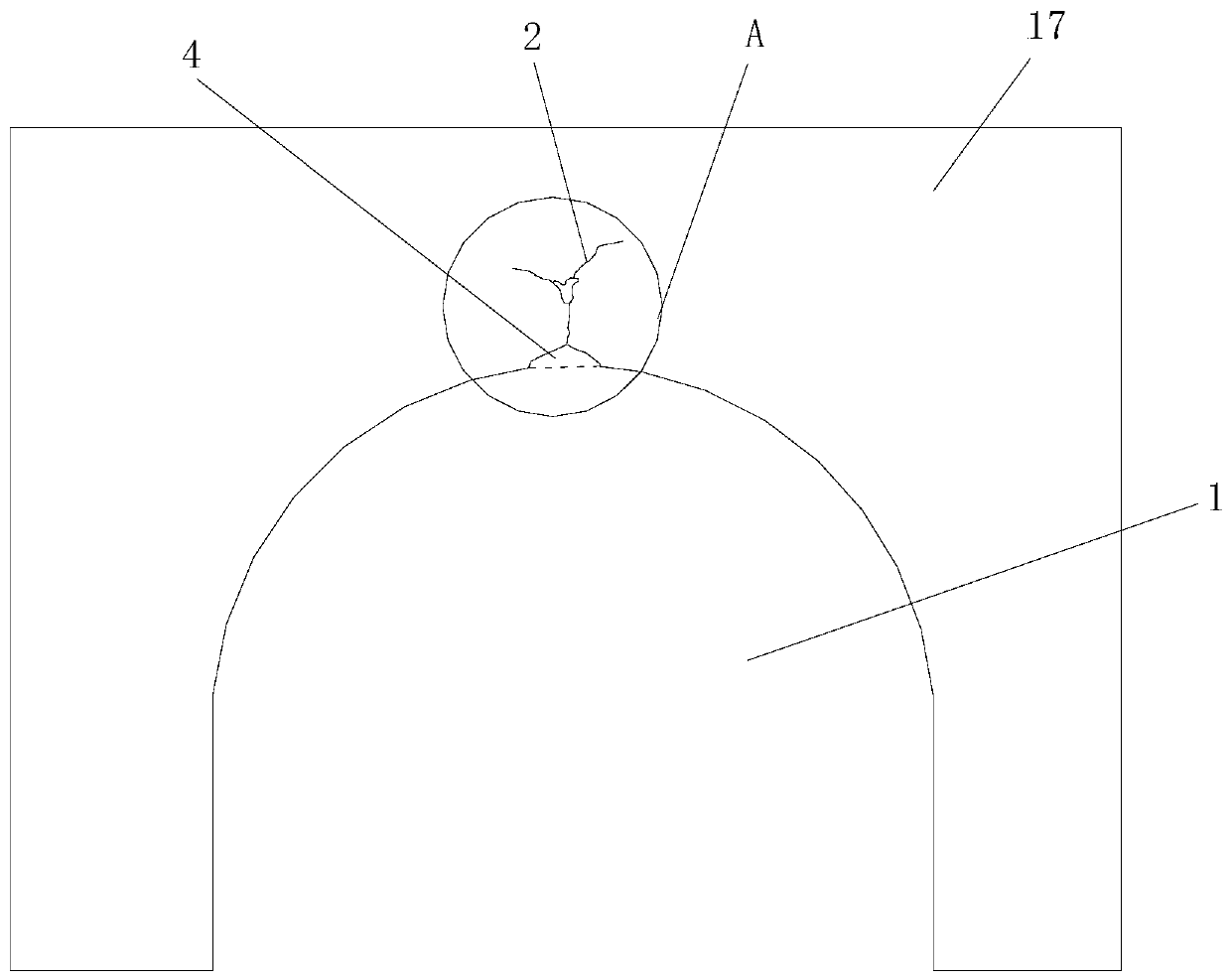

[0076] Such as figure 2 As shown in a loess cave dwelling seismic reinforcement method that replaces the covering soil in the sheared area of the vault, there are two cracks 2 in the covering soil layer above the arch ring of the reinforced loess cave dwelling 1, and the two cracks 2 are arranged crosswise. Arranged in an X shape, the overlapped gap between the two cracks 2 is an intersecting seam 13, the upper area of the intersecting seam 13 is a cavity 3, and the lower area of the intersecting seam 13 is a roof fall area 4, see figure 1 ;

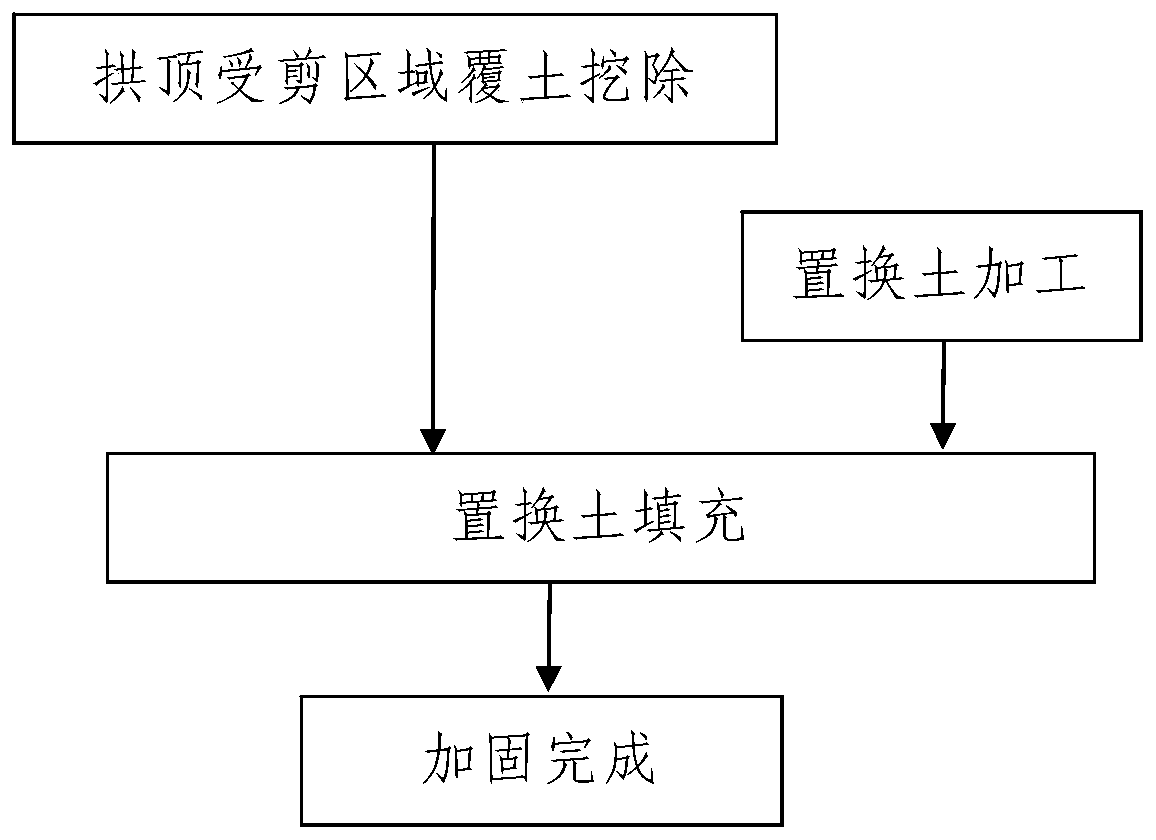

[0077] When the loess cave dwelling 1 is reinforced, the following steps are included:

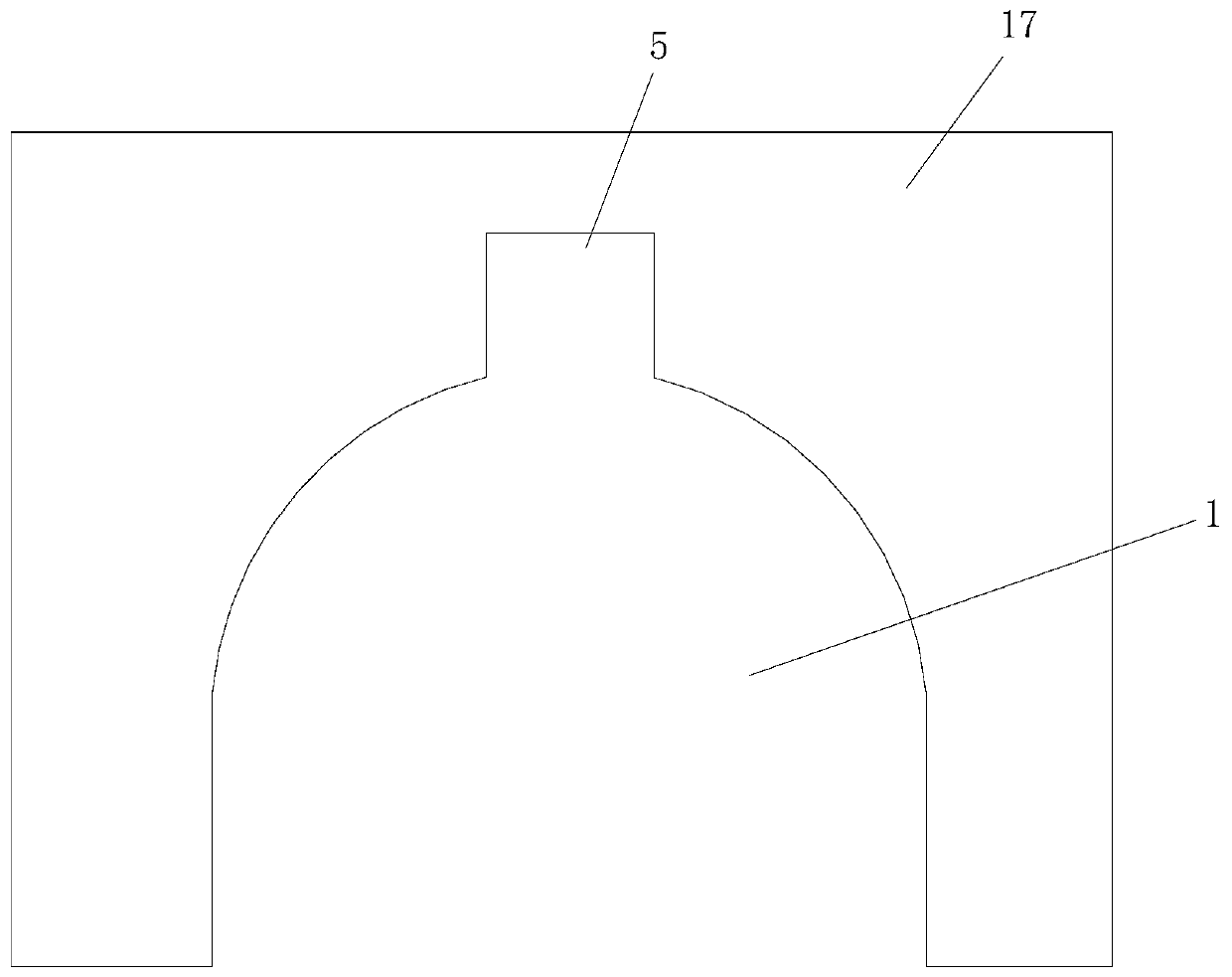

[0078] Step 1. Excavation of the overburden in the shear area of the vault: Excavate the overburden in the shear area of the vault in the overburden layer to obtain the shear replacement cavity 5 of the vault. For details, see image 3 ;

[0079] The two cracks 2 are located in the shear area of the vault, and the shear replacement ca...

Embodiment 2

[0130] Such as Figure 8 As shown, in this embodiment, the difference from Embodiment 1 is that in the step 2, a steel skeleton is arranged in the shear replacement layer 6 of the vault, and the steel skeleton is arranged horizontally and along the depth direction of the loess cave 1. Layout; the steel skeleton is a cube skeleton and it is fastened and fixed in the shear replacement layer 6 of the vault;

[0131] The steel bar skeleton includes four horizontally arranged stressed steel bars 12 and multiple vertically arranged tie bars 14, the four stressed reinforced bars 12 are arranged along the depth direction of the loess cave 1, and the four roads The length of the stressed steel bars 12 is the same as the depth of the loess cave 1, and they are respectively arranged on the top of the left and right sides and the lower parts of the left and right sides of the vault shear replacement cavity 5; the multiple tie bars 14 are all rectangular steel bars And they are all set on...

Embodiment 3

[0141] Such as Figure 9 As shown, in this embodiment, the difference from Embodiment 1 is that in step 1, a door-shaped tie net 7 is fixed in the vault shear replacement chamber 5, and the door-shaped tie net 7 is fixed by a It consists of a horizontal tension net on the top surface of the vault shear displacement chamber 5 and two vertical tension nets respectively fixed on the left and right side walls of the vault shear displacement chamber 5;

[0142] After the replacement soil is filled in step 2, the glyph-shaped tie net 7 is fixed between the vault shear replacement layer 6 and the covering soil layer on the side of the vault shear replacement cavity 5 .

[0143] In this embodiment, the horizontal tie net and the two vertical tie nets in the door-shaped tie net 7 are tightly connected as one, and the unfolded sheet of the door-shaped tie net 7 is one Integral rectangular mesh. The upper parts of the two vertical tie nets are respectively connected to the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com