An automatic cutting equipment for hardware pipe fittings

A technology for cutting equipment and pipe fittings, which is applied in the field of automatic cutting equipment for hardware pipe fittings, can solve the problems of large manual labor, unfavorable production efficiency, and low work efficiency, and achieve a high degree of automation, convenient feeding and cutting, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

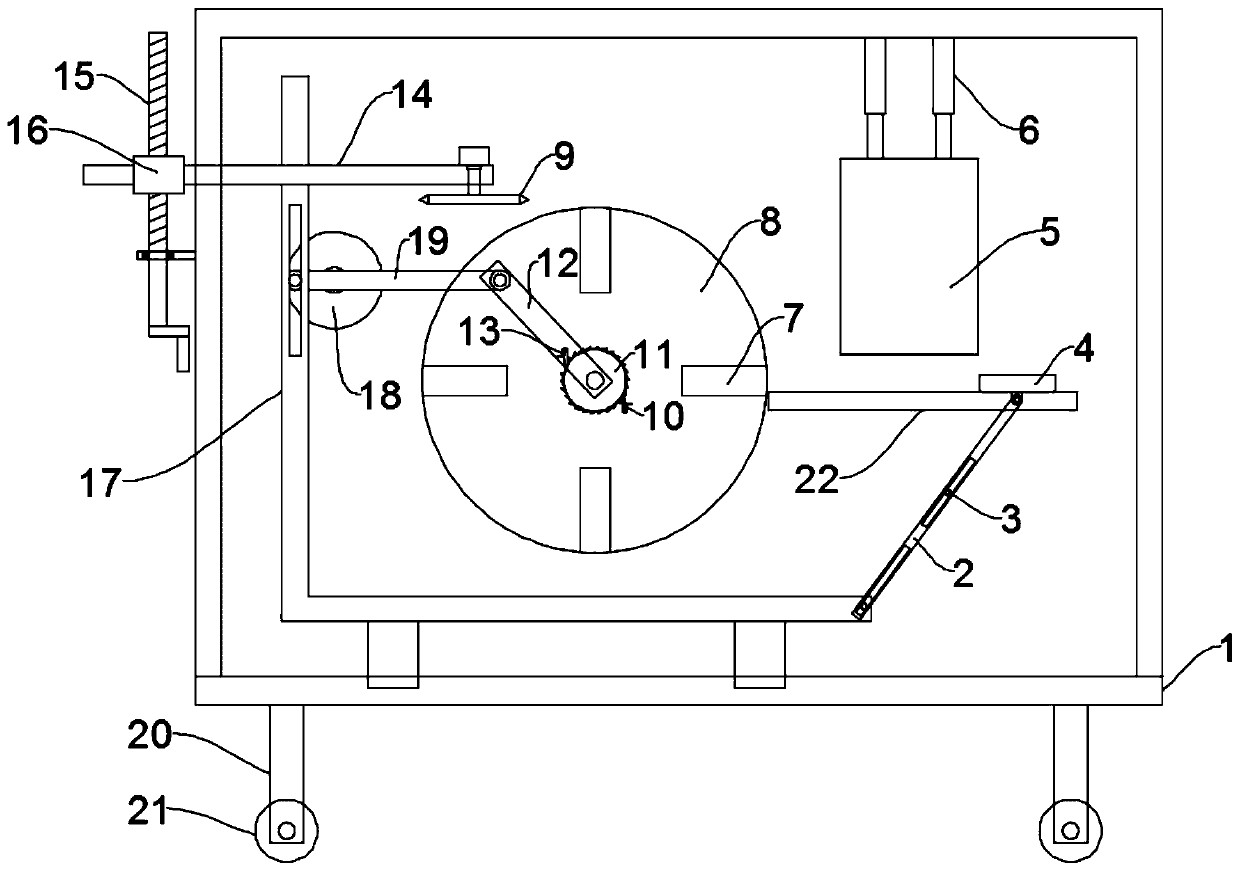

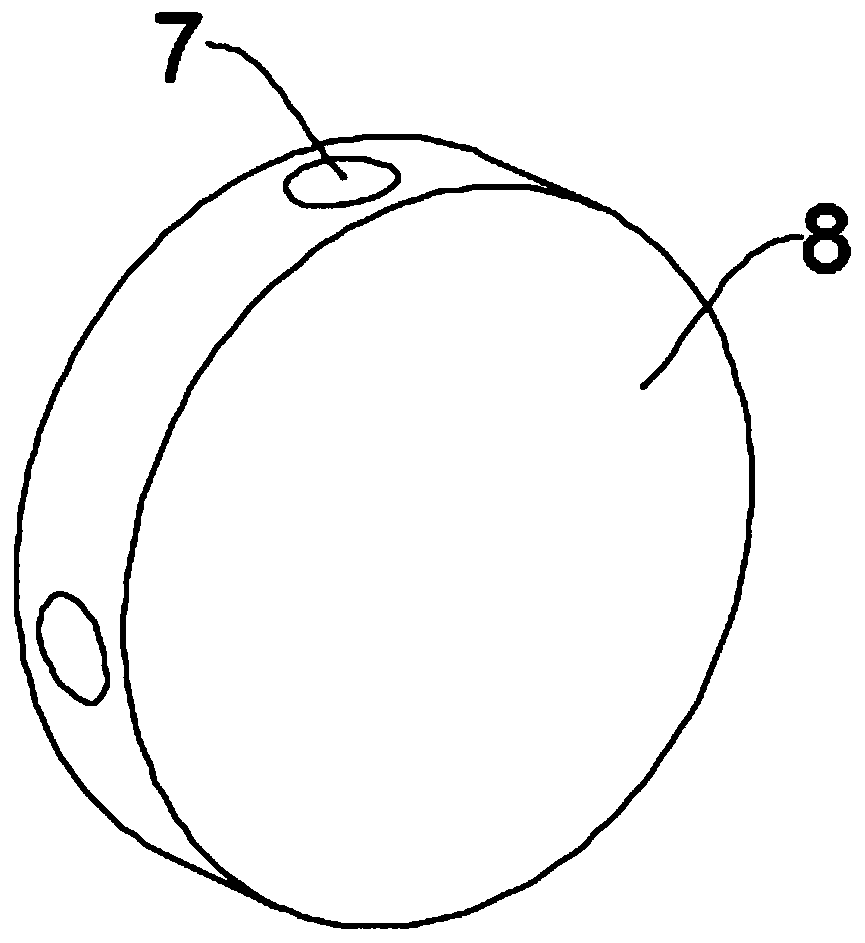

[0025] see Figure 1~2 , in the embodiment of the present invention, an automatic cutting equipment for metal pipe fittings, including a frame 1 and a cutting assembly 9, support legs 20 are evenly and symmetrically installed on the bottom of the frame 1, and rollers 21 are installed at the bottom of the support legs 20, the The roller 21 is a self-locking roller, and the cutting assembly 9 includes a cutting disc 18 and a drive motor for driving the disc 18 to rotate, and also includes a conveying mechanism that automatically transports the pipe to the cutting station for the cutting assembly 9 to cut, The conveying mechanism includes a drum 8, a pipe groove 7 provided on the drum 8 for accommodating pipe fittings, a feeding assembly for feeding pipe fittings into the pipe groove 7, and a driving mechanism for driving the drum 8 to rotate intermittently, The drum 8 is rotatably mounted on the frame 1, the feeding assembly includes a support plate 22, a hopper 5, a push block ...

Embodiment 2

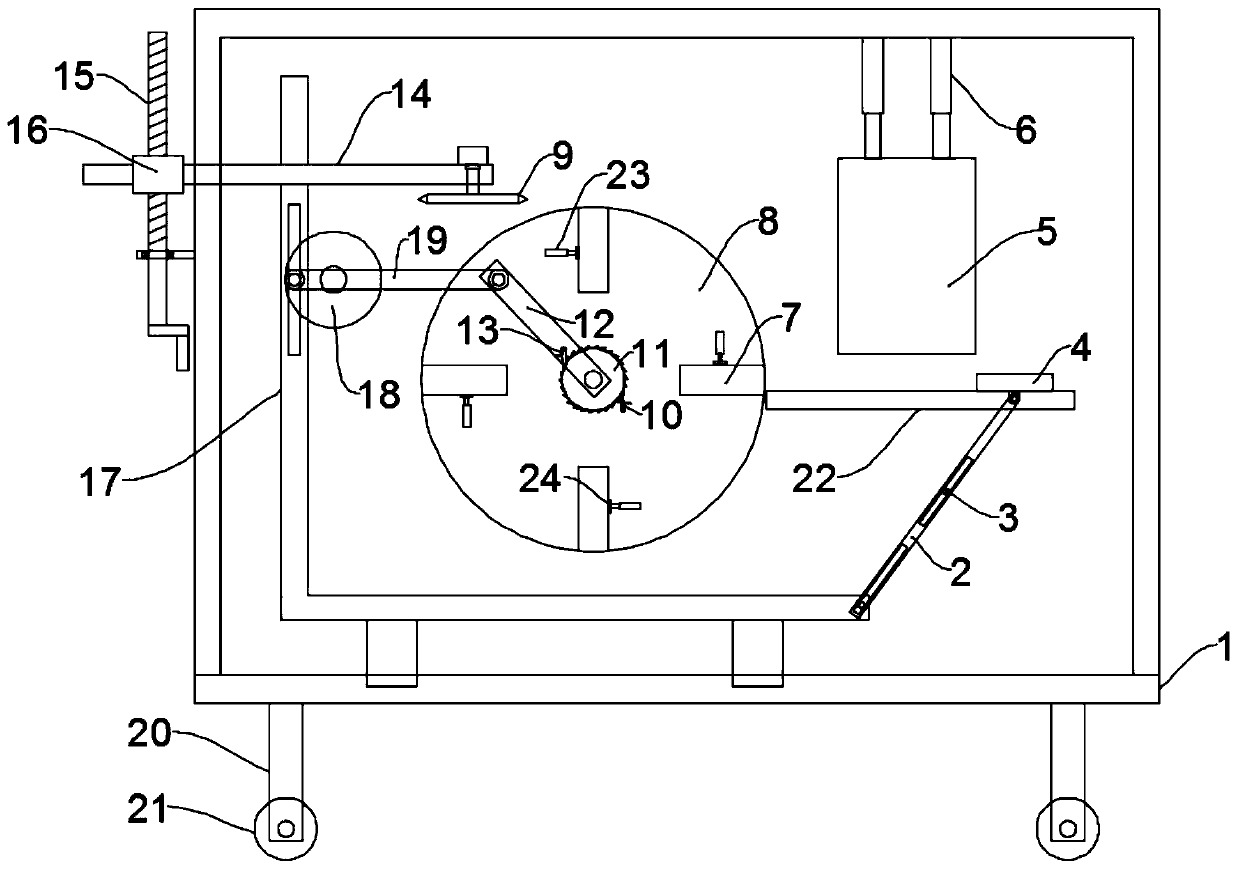

[0028] see image 3The difference between this embodiment of the present invention and Embodiment 1 is that further, in order to be able to adapt to pipes of different diameters, a second electric push rod 23 is installed on one side of the pipe groove 7 in the drum 8, and the second electric push rod 23 is installed on the side of the pipe groove 7. The end of the telescopic rod of the push rod 23 extends to the pipe groove 7 and is equipped with a positioning plate 24, which is stretched or shortened by the second electric push rod 23, so that the positioning plate 24 is pressed against pipe fittings of different diameters to facilitate cutting.

[0029] The working principle of the present invention is: when the present invention is in use, start the motor, the motor drives the disc 18 to rotate, the disc 18 drives the cylindrical pin to revolve, and the cylindrical pin drives the L-shaped rod 17 to reciprocate left and right, and the L-shaped rod 17 passes through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com