Wood-bamboo hollow forming wallboard reinforcing rib continuous built-in forming method and forming device

A molding device and reinforcing rib technology are applied in the direction of wood processing appliances, pretreatment of molding materials, hollow objects, etc., which can solve the problem of failure to meet the standard requirements of wood structure building wall materials, failure to achieve industrialized production, and low production efficiency and other issues, to achieve the effect of major economic value and social benefits, tight meshing, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further specifically described below through specific examples.

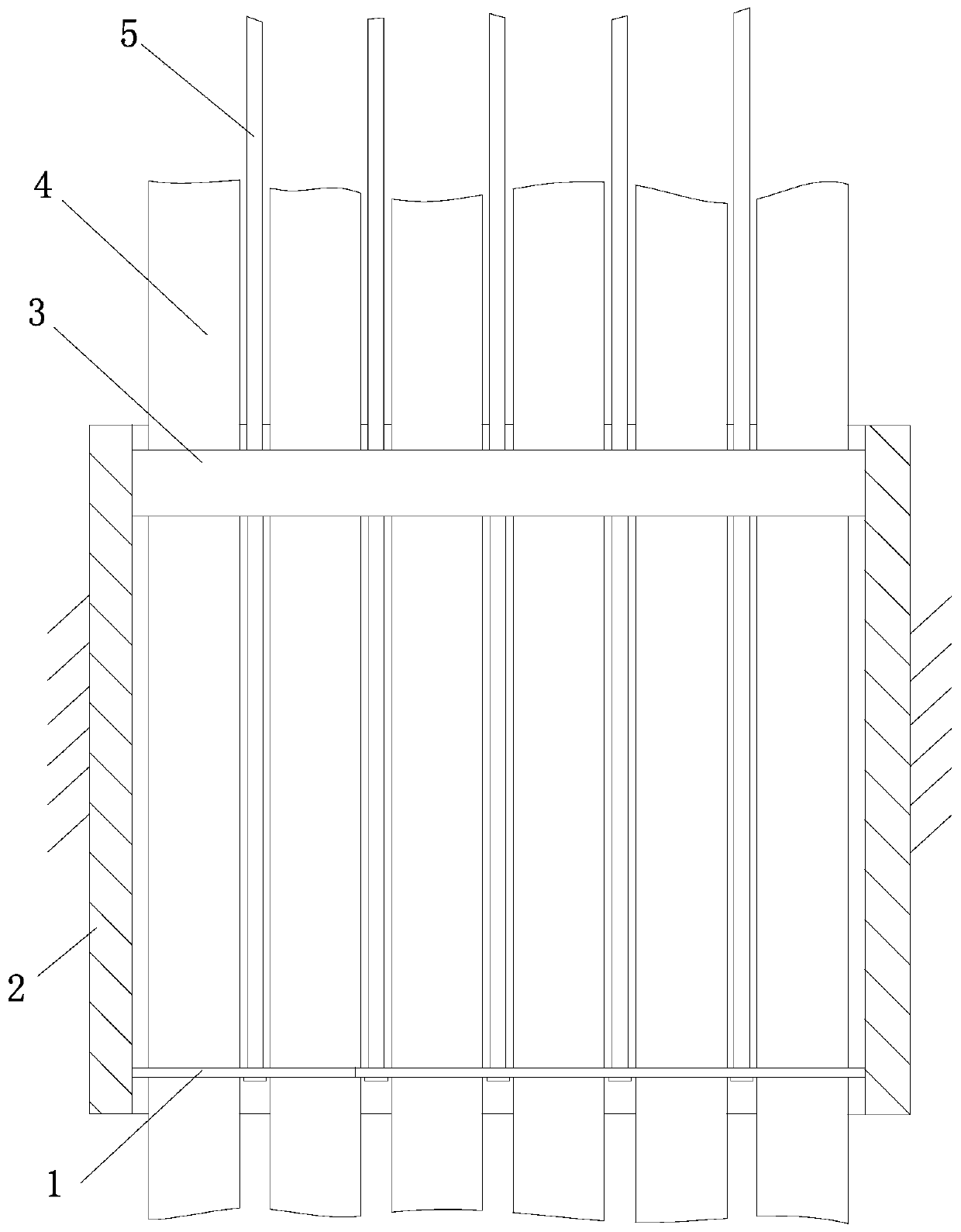

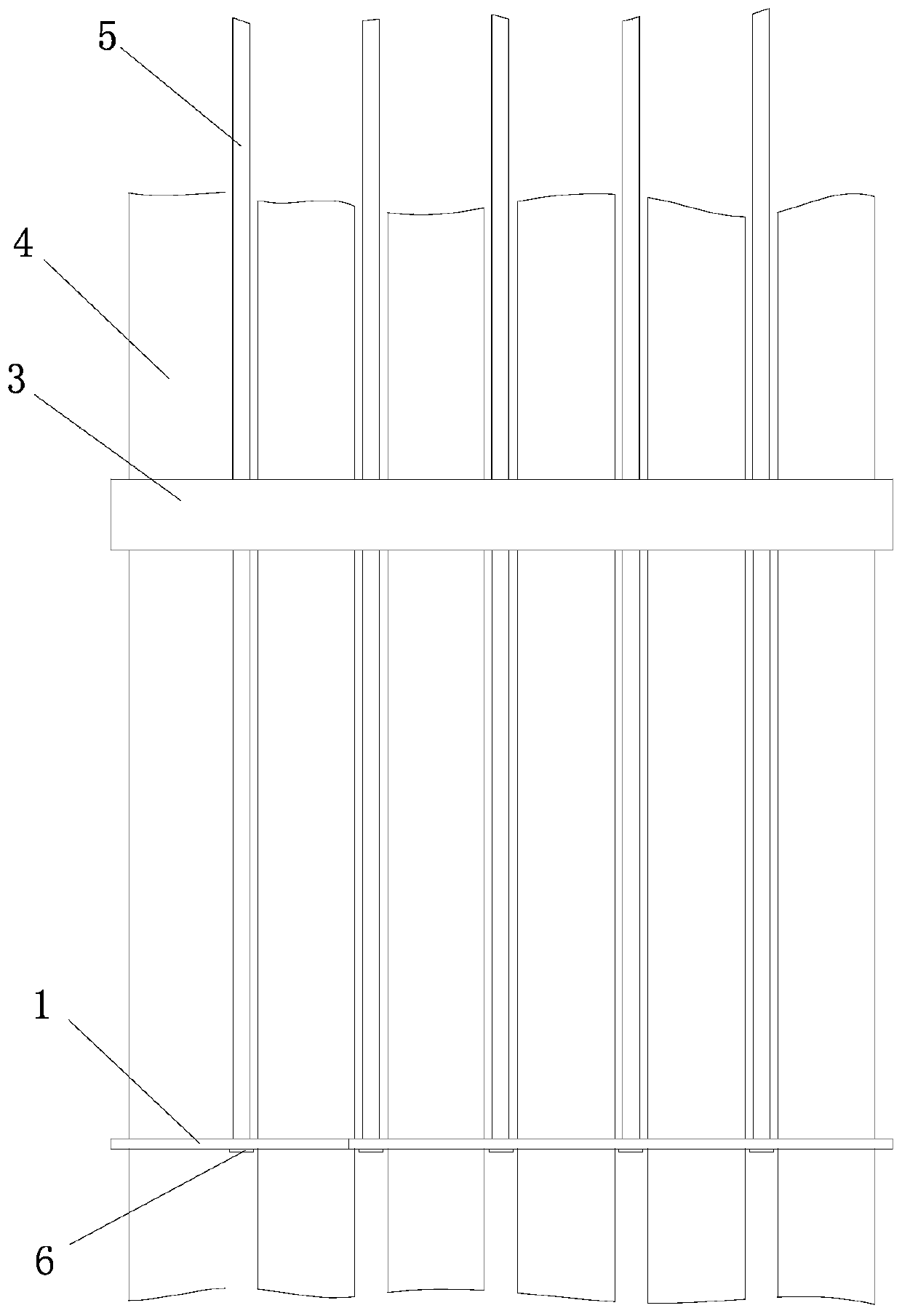

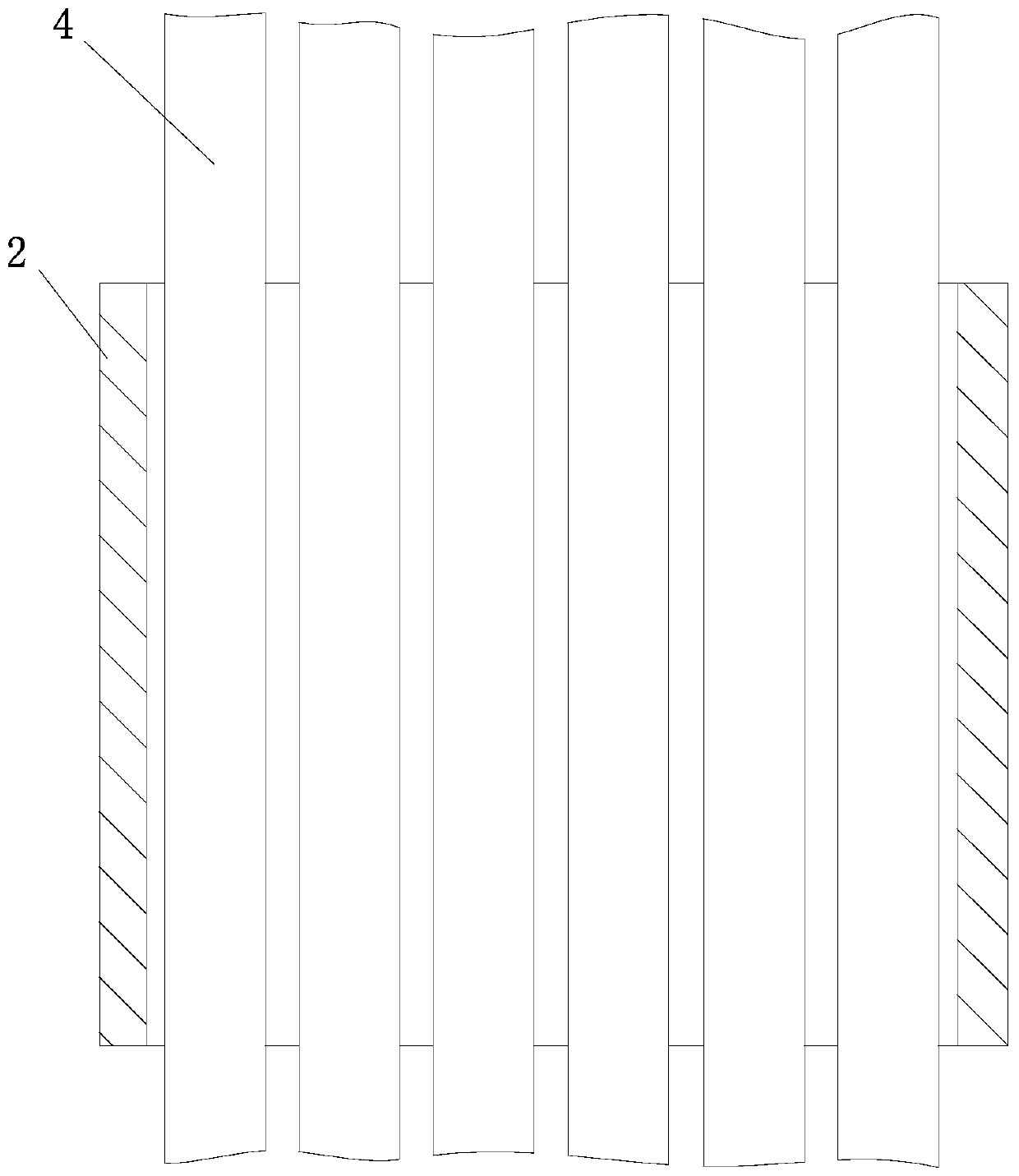

[0051] Wood and bamboo hollow forming wallboard K of the present invention (as Figure 25 As shown), its outer contour is a flat rectangular body, in which there are holes K1 arranged along the length direction and passing through both ends of the length direction; in addition, there are several reinforcing ribs K2, the extending direction of the reinforcing ribs and the extending direction of the holes Consistent, and the ribs are set between two holes and below the outer surface of the hollow slab to obtain better bonding strength with the hollow slab.

[0052] Because there are two methods for setting the reinforcing ribs of the existing wooden and bamboo hollow slabs (one is to preset openings when the wooden and bamboo hollow slabs are formed, and then insert the reinforcing ribs one by one after the wooden and bamboo hollow slabs are formed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com