Dry hanging drill bit

A drill and dry-hanging technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of affecting the aesthetics and stability of plates, uneven fixing of multiple plates, poor accuracy and stability, etc. Drilling Efficiency and Drilling Quality, Reduced Drilling Quality Degradation, Effect of Controlling Drilling Depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment proposes a dry-hanging drill bit that is easy to discharge slag and drain and control the drilling depth, so as to improve drilling efficiency and drilling quality.

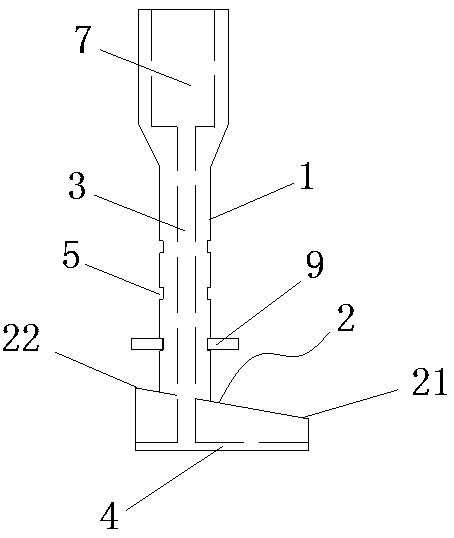

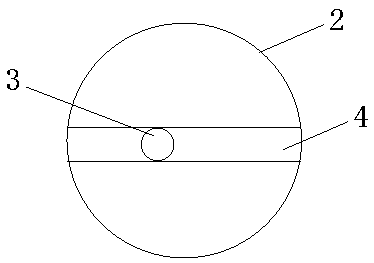

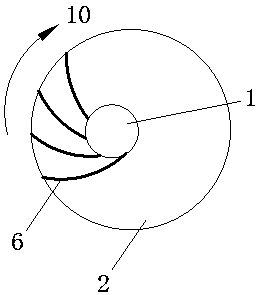

[0019] Such as figure 1 , 2 As shown, the dry-hanging drill bit of this embodiment is composed of a drill rod 1 and a cutting head 2 welded to the bottom end of the drill rod 1 in an eccentric state. The top of the hole 3 is connected to the threaded assembly hole 7 of the drill pipe 1; the bottom surface of the cutting head 2 is provided with a water guide groove 4 communicating with the water guide hole 3, and the two ends of the water guide groove 4 extend to the head end 21 of the cutting head 2 respectively. and the tail end 22; the bottom surface of the cutting head 2 is a plane, the cutting head 2 is circular, and its head end 21 is farther away from the drill pipe 1 than the tail end 22, and the thickness of the cutting head 2 gradually increases from the head end 21 to the tail en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com