Injection molding mold assembly convenient to disassemble and assemble

A technology of injection molding and mould, applied in the field of injection molding mold components, can solve the problems of inconvenient maintenance and repair cleaning, unreasonable structure setting, complex structure, etc., and achieve compact structure, easy disassembly and maintenance, and stable bottom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

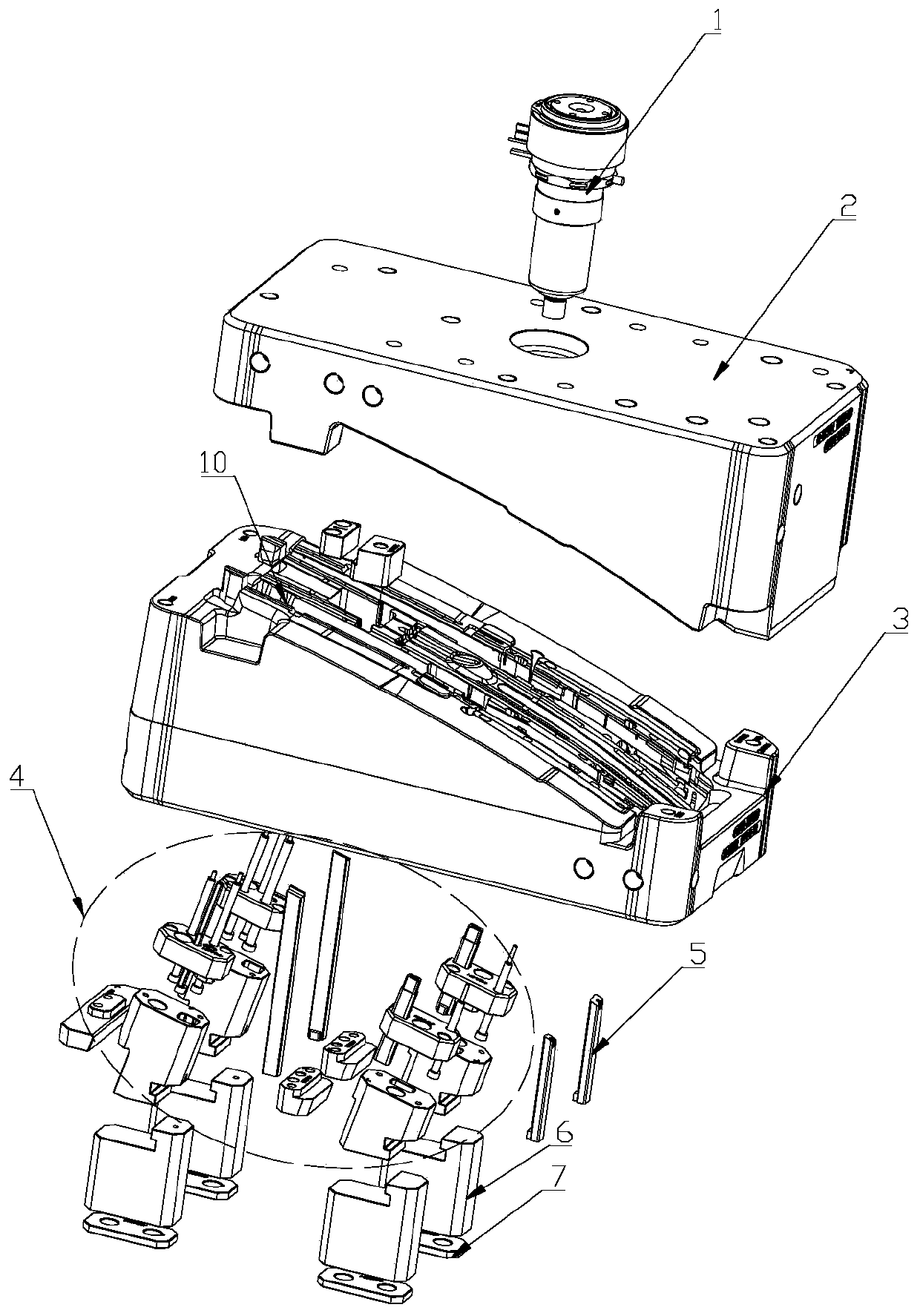

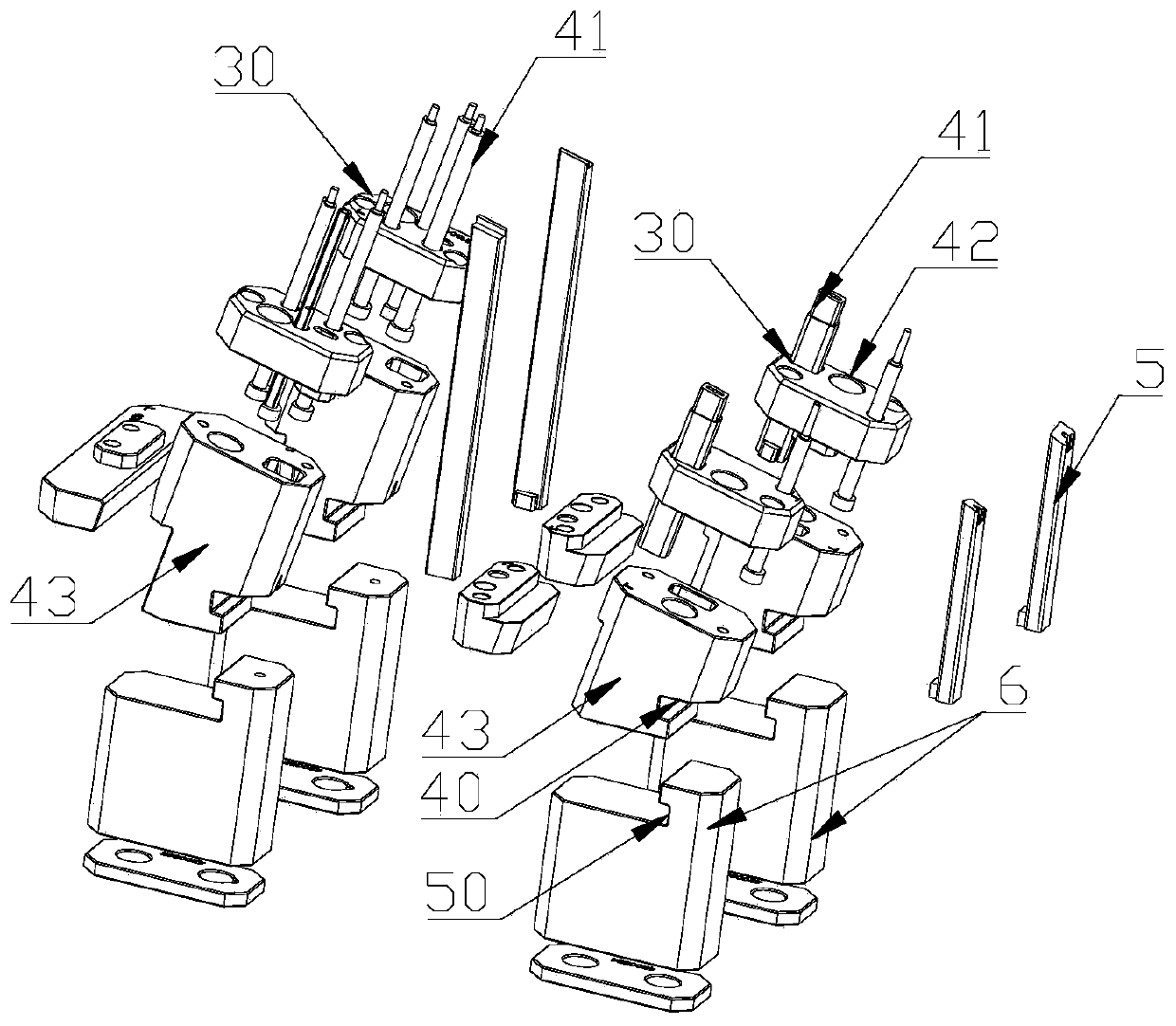

[0023] Such as figure 1 As shown, an injection molding mold assembly that is easy to disassemble includes a hot nozzle 1, a front mold core 2, and a rear mold core 3. The hot nozzle 1 is sleeved in the front mold core 2, and the rear mold core 3 is arranged on the lower side of the front mold core 2, and the rear mold core 3 is provided with a plurality of row insert assemblies 4 and a rear mold insert 5, and the lower end of the row insert assemblies 4 is also provided with There is a shovel base 6 and a shovel base block 7, a mold product cavity 10 is formed between the front mold core 2 and the rear mold core 3, and the hot nozzle 1 is used to inject molten plastic material into the mold from the nozzle of the injection molding machine Internal entrance.

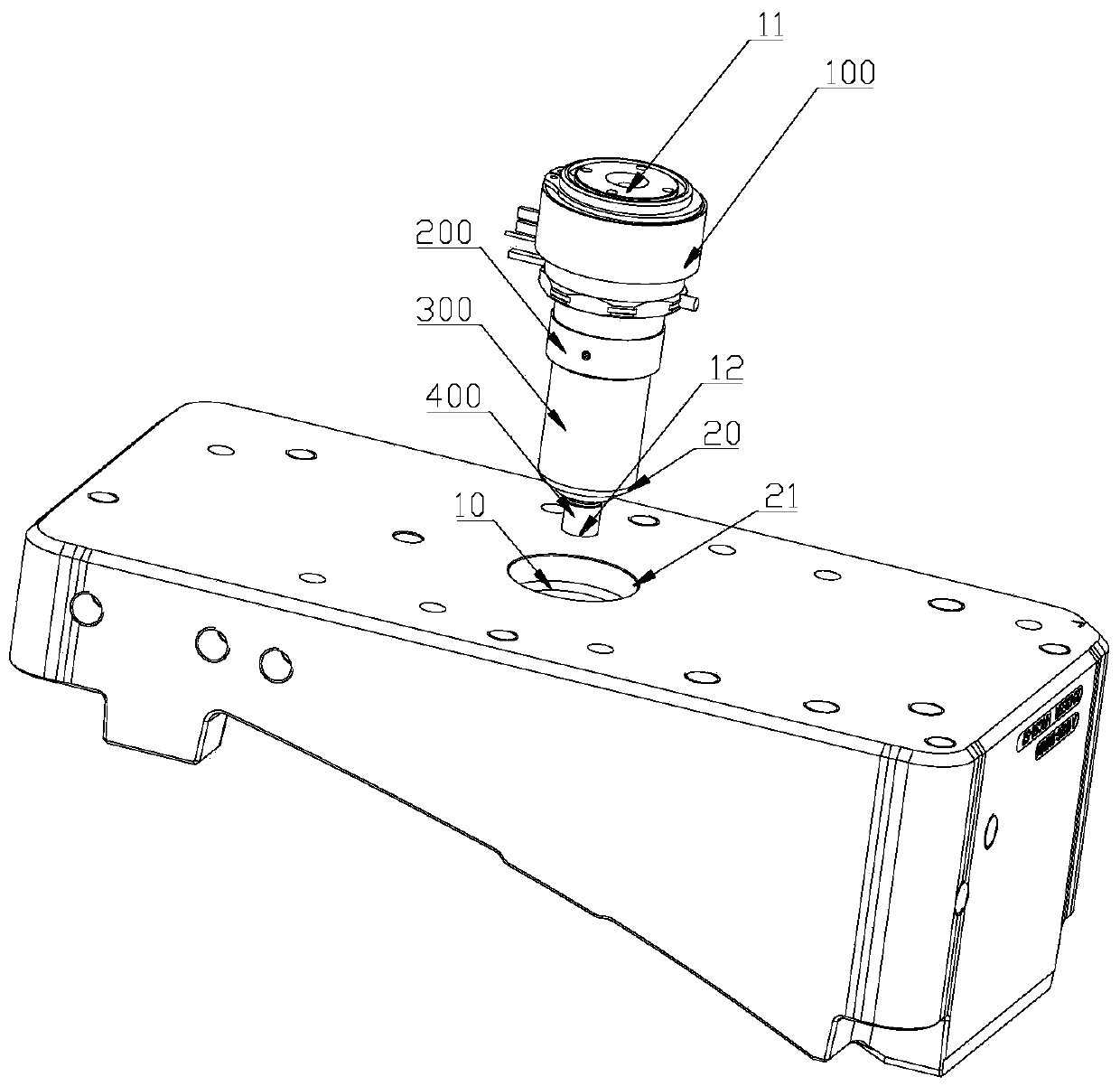

[0024] combine figure 2 As shown, the upper end of the hot nozzle 1 is provided with an injection inlet 11, and the lower end is provided with an injection outlet 12, and an injection flow channel is formed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com