Polycarboxylic acid highly-slump-retaining additive for concrete and preparation method thereof

An admixture, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve problems such as difficult pumping, large loss of concrete slump, poor fluidity, etc., to improve slump retention performance and workability, and facilitate on-site construction , Guarantee the effect of constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

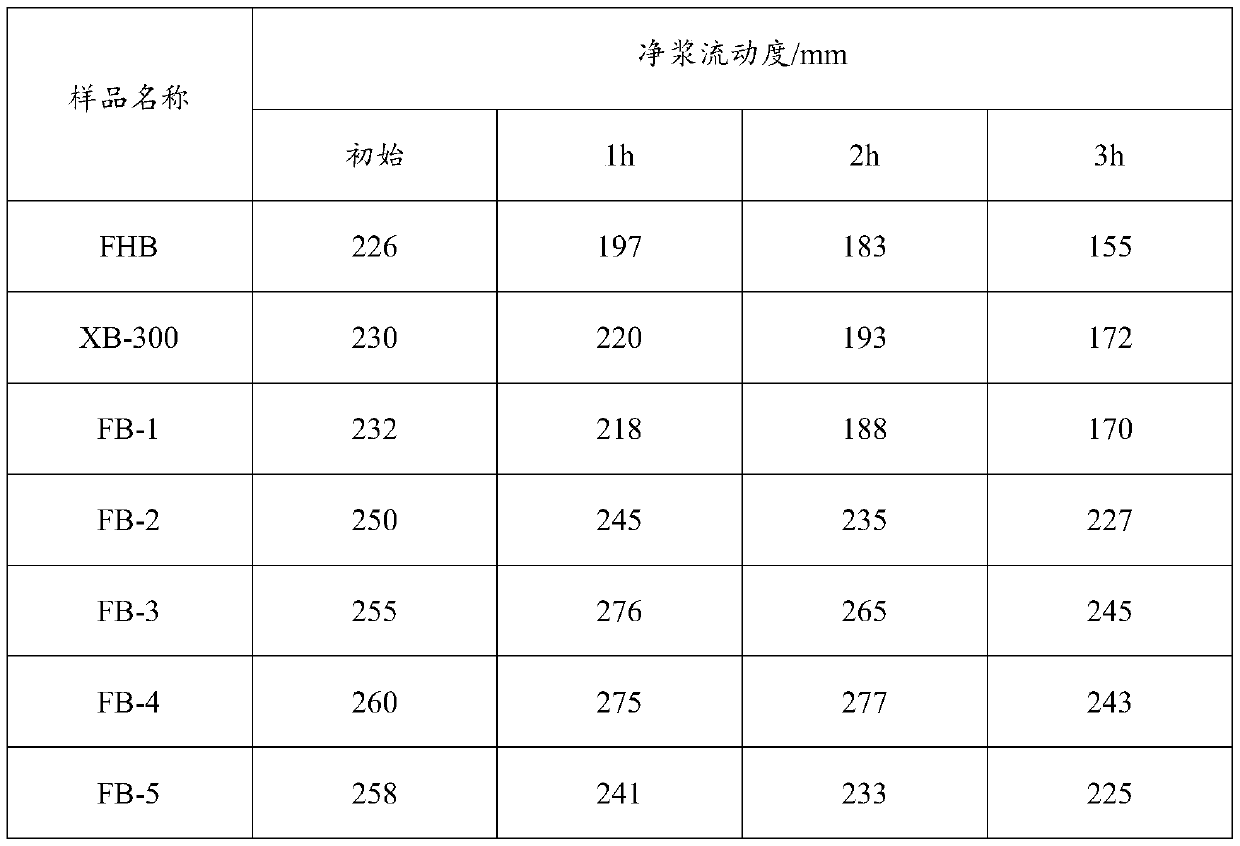

Embodiment 1

[0038] Prepare material A: add 50.45g of water to the container, then add 21.18g of AA, 0.22g of HA and AM, mix well and set aside;

[0039] Prepare material B: add 69.29g of water to the container, then add 0.81g of TGA and 0.4g of VC, mix well and set aside;

[0040] Add 120g of water into the reactor, then put in 180g of TPEG, start stirring until it is fully dissolved, and raise the temperature to 50°C; when the TPEG is completely dissolved, add 1g of initiator hydrogen peroxide, stir for 30min, then start to drop A and B materials, A The material is added dropwise for 1-4 hours, the material B is added dropwise for 1-5 hours, after the completion of the dropwise addition, it is incubated for 1-4 hours, then neutralized to neutral with 30% NaOH, and finally 56.43g of water is added to obtain the product FB-2.

Embodiment 2

[0042] Prepare material A: add 50.45g of water to the container, then add 20.32g of AA, 0.65g of HA and AM, mix well and set aside;

[0043] Prepare material B: add 69.29g of water to the container, then add 0.81g of TGA and 0.4g of VC, mix well and set aside;

[0044] Add 120g of water into the reactor, then put in 180g of TPEG, start stirring until it is fully dissolved, and raise the temperature to 50°C; when the TPEG is completely dissolved, add 1g of initiator hydrogen peroxide, stir for 30min, then start to drop A and B materials, A The material is added dropwise for 1-4 hours, and the material B is added dropwise for 1-5 hours. After the dropwise addition, it is incubated for 1-4 hours, then neutralized to neutral with 30% NaOH, and finally 56.43 g of water is added to obtain the product FB-3.

Embodiment 3

[0046] Prepare material A: add 50.45g of water to the container, then add 19.46g of AA, 1.08g of HA and AM, mix well and set aside;

[0047]Prepare material B: add 69.29g of water to the container, then add 0.81g of TGA and 0.4g of VC, mix well and set aside;

[0048] Add 120g of water into the reactor, then put in 180g of TPEG, start stirring until it is fully dissolved, and raise the temperature to 50°C; when the TPEG is completely dissolved, add 1g of initiator hydrogen peroxide, stir for 30min, then start to drop A and B materials, A The material is added dropwise for 1-4 hours, the material B is added dropwise for 1-5 hours, after the dropwise addition is completed, it is incubated for 1-4 hours, then neutralized to neutral with 30% NaOH, and finally 56.43 g of water is added to obtain the product FB-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com