Full-continuous polylactic acid production equipment and technological process

A production equipment and polylactic acid technology, applied in the field of production equipment and process flow of fully continuous polylactic acid, can solve problems such as poor fluidity, and achieve the effects of large process adjustment range, improved order removal efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

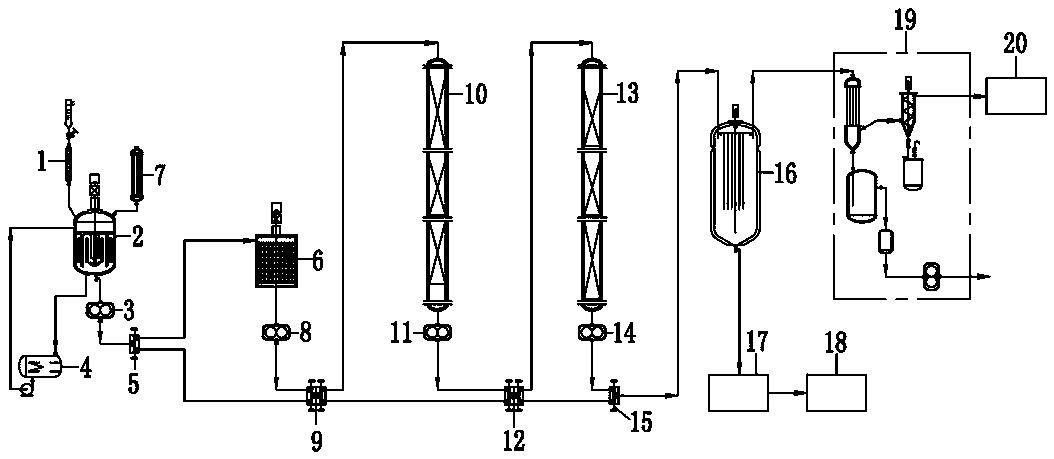

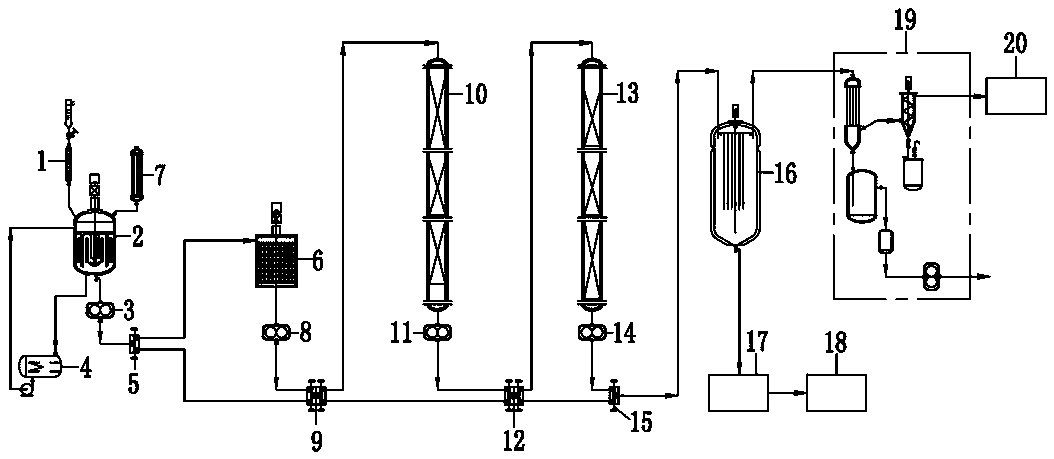

[0018] Such as figure 1 as shown in figure 1 A fully continuous polylactic acid production equipment and process flow are shown, mainly including a first polymerization tank 2, a reflux condenser 7, a second polymerization tank 6, a third polymerization tower 10, a fourth polymerization tower 13, and a single removal tank 16 , Underwater granulator 18, vacuum packaging machine 19, vacuum pump unit 20.

[0019] Such as figure 1 A full-continuous polylactic acid production equipment is shown. The slurry configured from the melting dispensing device 1 enters the first polymerization kettle 2 for preliminary polymerization. The first polymerization kettle 2 is a jacketed structure and is connected to an independent heat medium system 4. Independent temperature adjustment, the first gear pump 3 is provided at the bottom of the first polymerization kettle 2, and the first gear pump 3 is connected with the first three-way valve 5 to adjust the direction of the melt and adapt to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com