Method for extracting selenium polypeptide from selenium-rich passion fruit seeds

A technology of passion fruit seeds and passion fruit, which is applied in the field of polypeptide extraction, can solve the problems of waste of selenium-enriched passion fruit seeds, and achieve the effects of saving repeated protein extraction steps, avoiding the loss of selenium polypeptides, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

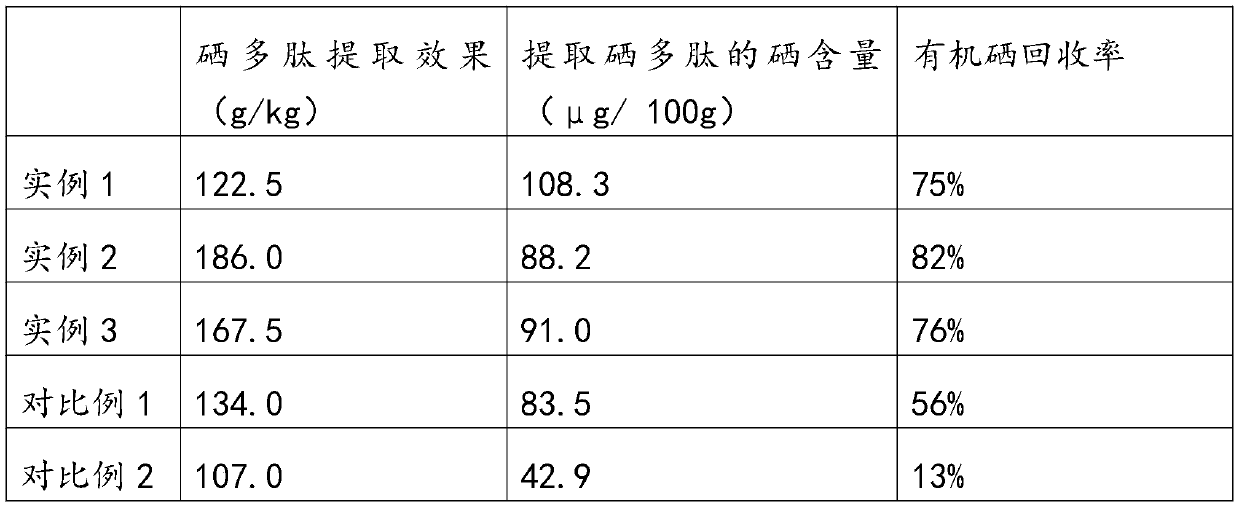

[0028] A method for extracting selenium polypeptide from selenium-enriched passion fruit seeds, the following is one or more preferred embodiments, and its specific steps are as follows:

[0029] 1. Take the selenium-enriched passion fruit, cut it in half with a knife, dig out the pulp with seeds, use a three-legged centrifuge, filter with a density of 20 mesh, and centrifuge at a speed of 5000r / min for 5min. Collect the passion fruit seeds inside the strainer.

[0030] 2. Wash the passion fruit seeds with clean water, dry them, crush them with a Chinese herbal medicine grinder, and pass through a 60-mesh sieve to remove most of the hard shells. The sieved powder is added with water according to the ratio of material to liquid 1:10 (g / mL), and homogenized with a colloid mill. The homogenization temperature is 25°C, the gap between the colloid mill is 0.1 mm, and the homogenization time is 5 minutes.

[0031] 3. The homogenized mixture passes through a 200-mesh sieve, and is t...

Embodiment 2

[0037] A method for extracting selenium polypeptide from selenium-enriched passion fruit seeds, the following is one or more preferred embodiments, and its specific steps are as follows:

[0038]1. Take the selenium-enriched passion fruit, cut it in half with a knife, dig out the seed pulp with a pulper (or by hand), use a three-legged centrifuge, filter with a density of 20 mesh, and centrifuge at a speed of 5000r / min for 8 minutes. Collect the passion fruit seeds inside the strainer.

[0039] 2. Wash the passion fruit seeds with clean water, dry them, crush them with a Chinese herbal medicine grinder, and pass through a 60-mesh sieve to remove most of the hard shells. The sieved powder is added with water according to the ratio of material to liquid 1:10 (g / mL), and homogenized with a colloid mill, wherein the homogenization temperature is 25°C, the colloid mill gap is 1 mm, and the homogenization time is 10 minutes.

[0040] 3. The homogenized mixture passes through a 200-...

Embodiment 3

[0046] A method for extracting selenium polypeptide from selenium-enriched passion fruit seeds, the following is one or more preferred embodiments, and its specific steps are as follows:

[0047] 1. Take the selenium-enriched passion fruit, cut it in half with a knife, dig out the pulp with seeds, use a three-legged centrifuge, filter with a density of 20 mesh, and centrifuge at a speed of 5000r / min for 6 minutes. Collect the passion fruit seeds inside the strainer.

[0048] 2. Wash the passion fruit seeds with clean water, dry them, crush them with a Chinese herbal medicine grinder, and pass through a 60-mesh sieve to remove most of the hard shells. The sieved powder is added with water according to the ratio of material to liquid 1:10 (g / mL), and homogenized with a colloid mill. The homogenization temperature is 25°C, the gap between the colloid mill is 0.5mm, and the homogenization time is 8 minutes.

[0049] 3. The homogenized mixture passes through a 200-mesh sieve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com