Blast furnace slag taking and conveying and slag pool toxic water vapor pollution treatment comprehensive system

A blast furnace slag and pollution treatment technology, applied in the field of environmental treatment, to achieve the effect of saving investment, easy implementation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

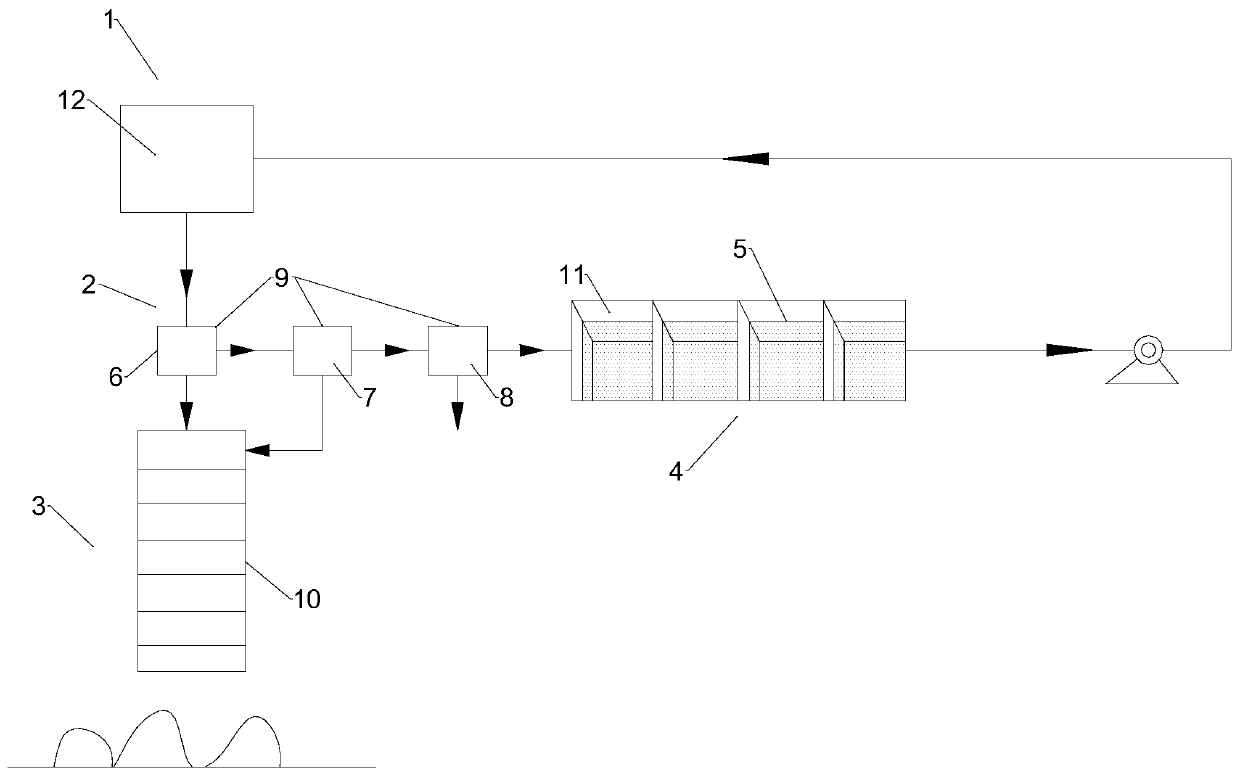

Embodiment 1

[0043] see figure 1 , providing a comprehensive system for taking and delivering blast furnace slag and controlling toxic water vapor pollution in slag ponds, including a slag flushing unit 1, a slag and water separation unit 2, a slag conveying unit 3 and a water storage unit 4; the slag flushing unit 1 includes flushing A slag pool 12 and a slag flushing ditch, the slag and water separation unit 2 includes a slag and water separation part 9, the slag conveying unit 3 includes a slag conveying part 10, and the water storage unit 4 includes a clean water storage part 11; The slag flushing trench 12 is connected to the slag and water separation part 9 through the slag flushing trench, and the slag and water separation part 9 is respectively connected to the slag conveying part 10 and the clean water storage part 11, and the slag and water separation part 9 will separate The finished slag is transferred to the slag conveying part 10, and the slag and water separation part 9 tran...

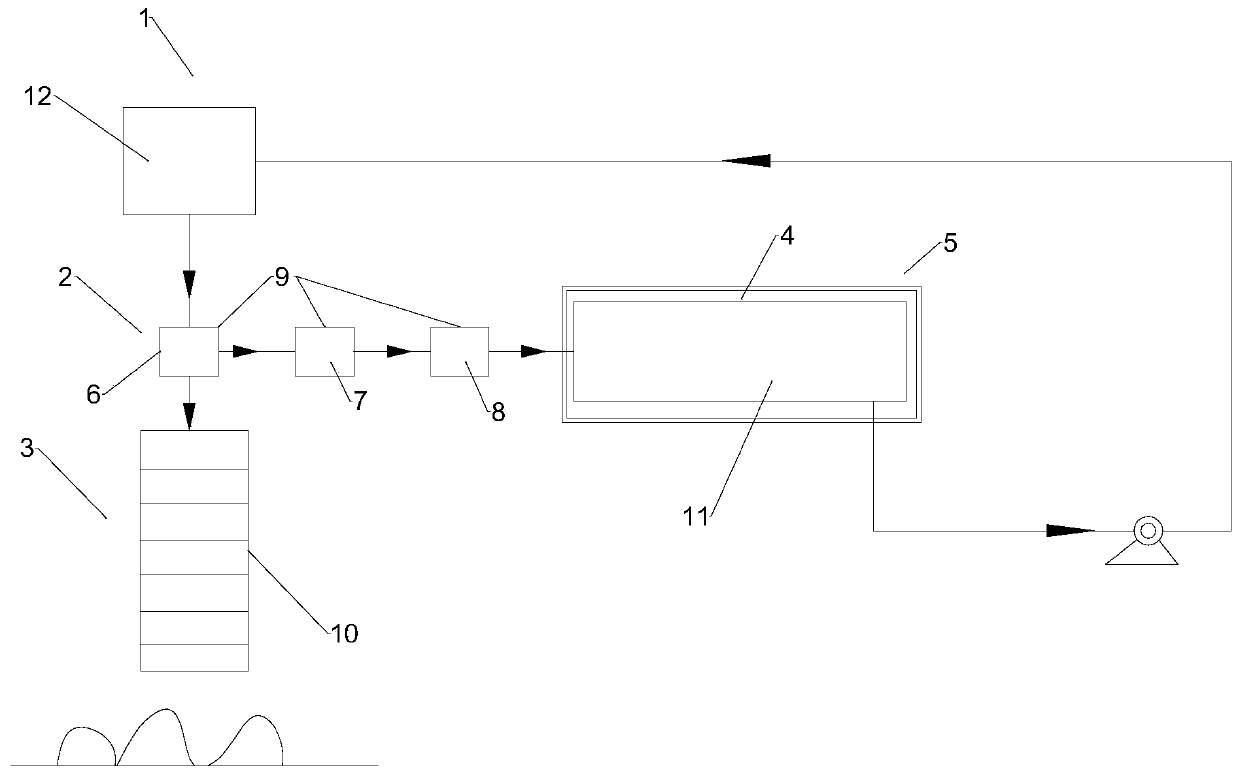

Embodiment 2

[0049] see figure 2 , providing a comprehensive system for taking and delivering blast furnace slag and controlling toxic water vapor pollution in slag ponds, including a slag flushing unit 1, a slag and water separation unit 2, a slag conveying unit 3 and a water storage unit 4; the slag flushing unit 1 includes flushing A slag pool 12 and a slag flushing ditch, the slag and water separation unit 2 includes a slag and water separation part 9, the slag conveying unit 3 includes a slag conveying part 10, and the water storage unit 4 includes a clean water storage part 11; The slag flushing tank 12 is connected to the slag and water separation part 9 through the slag flushing ditch, and the slag and water separation part 9 is respectively connected to the slag conveying part 10 and the clean water storage part 11, and the slag and water separation part 9 will separate The finished slag is transferred to the slag conveying part 10, and the slag and water separation part 9 transf...

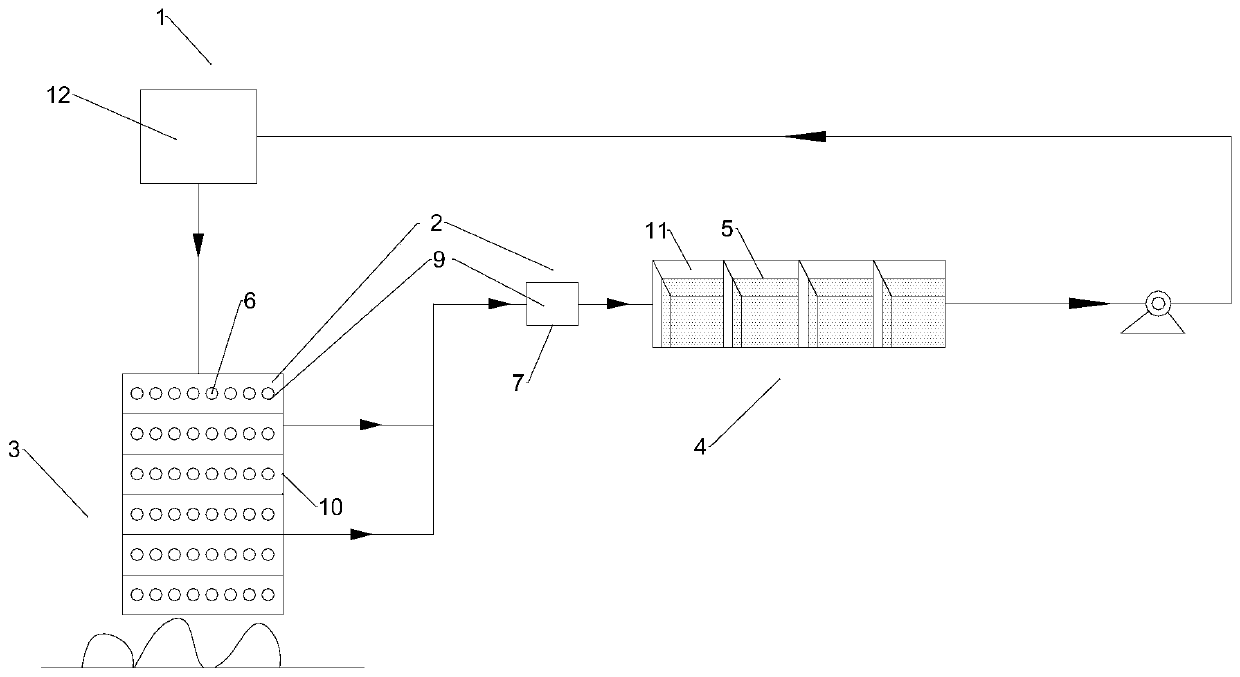

Embodiment 3

[0055] see image 3 , providing a comprehensive system for taking and delivering blast furnace slag and controlling toxic water vapor pollution in slag ponds, including a slag flushing unit 1, a slag and water separation unit 2, a slag conveying unit 3 and a water storage unit 4; the slag flushing unit 1 includes flushing A slag pool 12 and a slag flushing ditch, the slag and water separation unit 2 includes a slag and water separation part 9, the slag conveying unit 3 includes a slag conveying part 10, and the water storage unit 4 includes a clean water storage part 11; The slag flushing tank 12 is connected to the slag and water separation part 9 through the slag flushing ditch, and the slag and water separation part 9 is respectively connected to the slag conveying part 10 and the clean water storage part 11, and the slag and water separation part 9 will separate The finished slag is transferred to the slag conveying part 10, and the slag and water separation part 9 transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com