An oil pipeline cleaning and detection robot

A technology for oil pipelines and robots, applied in the field of robots, can solve the problems of rising resistance in the pipeline and hindering fluid flow, and achieve the effects of reasonable structure, high work efficiency and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

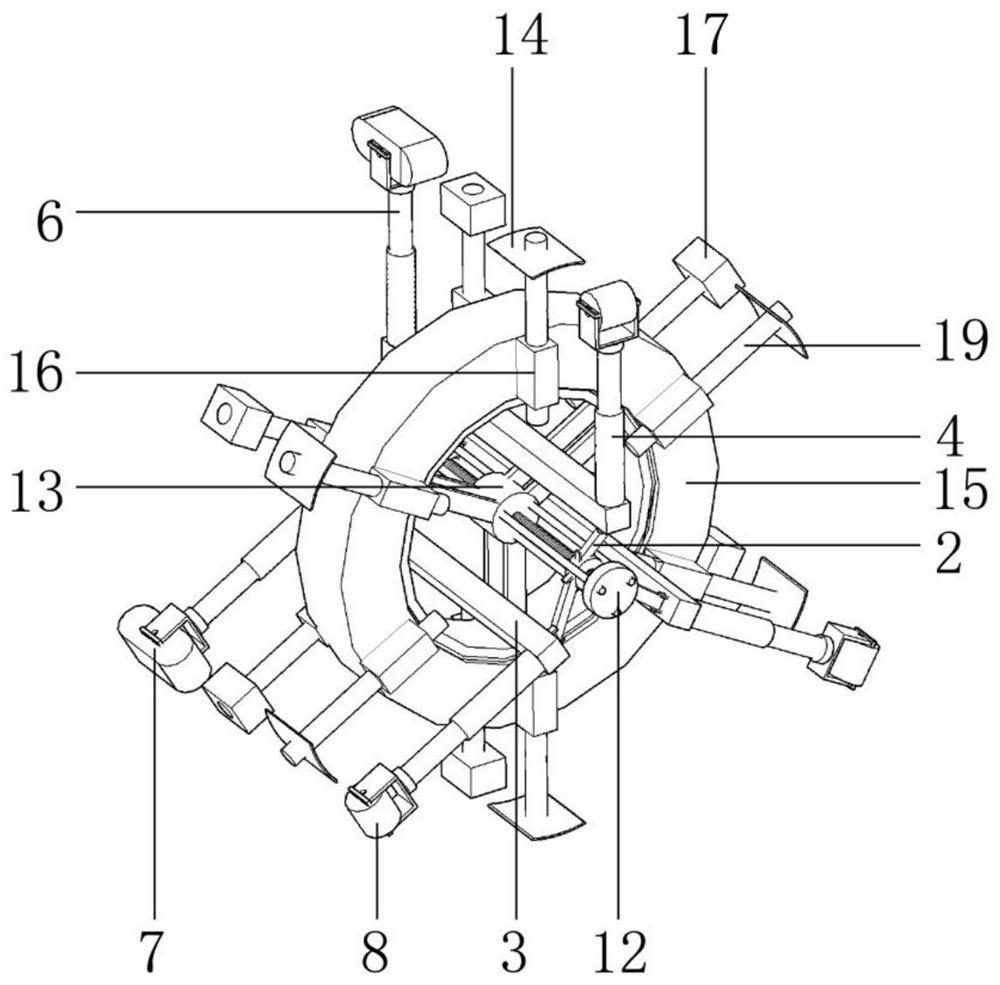

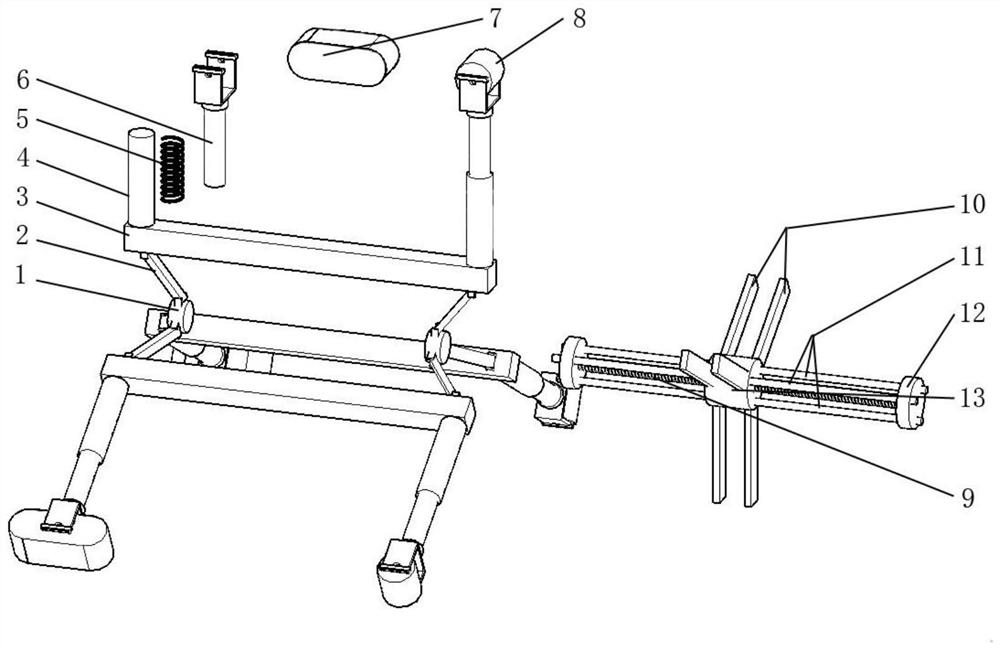

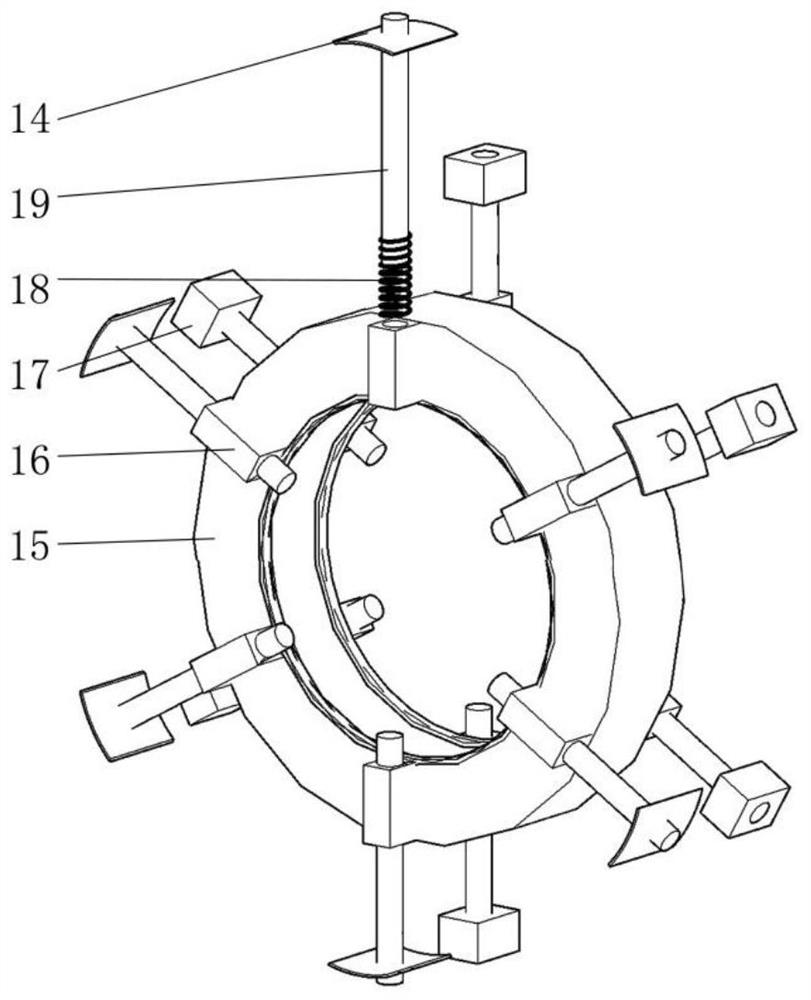

[0024] The structural principle and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] An oil pipeline cleaning and detection robot, including a traveling mechanism, a cleaning and detection mechanism, and a control mechanism;

[0026] see figure 1 , figure 2 , the walking mechanism includes a shaft motor 13, the shaft motor 13 is a biaxial motor, and the two ends of the shaft motor 13 are symmetrically arranged with two groups of radial tripod supports 10 arranged around the shaft center of the shaft motor 13; The power output end of the heart motor 13 is connected to one end of the screw rod 9 on both sides through the couplings arranged symmetrically on both sides respectively, and the other end of the screw rod 9 is connected to the fixed support 12 through the bearing, and the fixed support on both sides 12 and the axis motor 13 are respectively symmetrically provided with three fixed poles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com