Method for measuring and calculating dispersity of load type metal catalyst based on atomic resolution electron microscope

A metal-loaded, dispersity technology, applied in material analysis using radiation, material analysis using radiation diffraction, etc., can solve the problem of lack of catalyst dispersion measurement method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

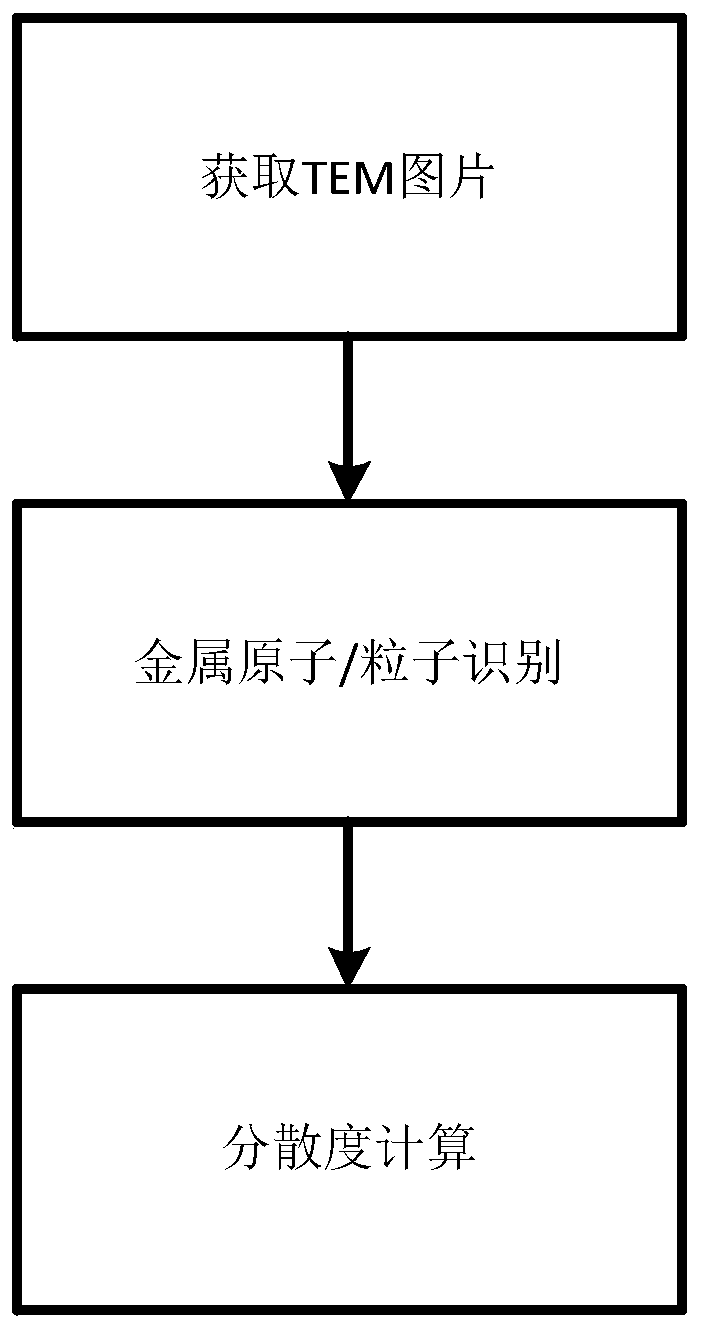

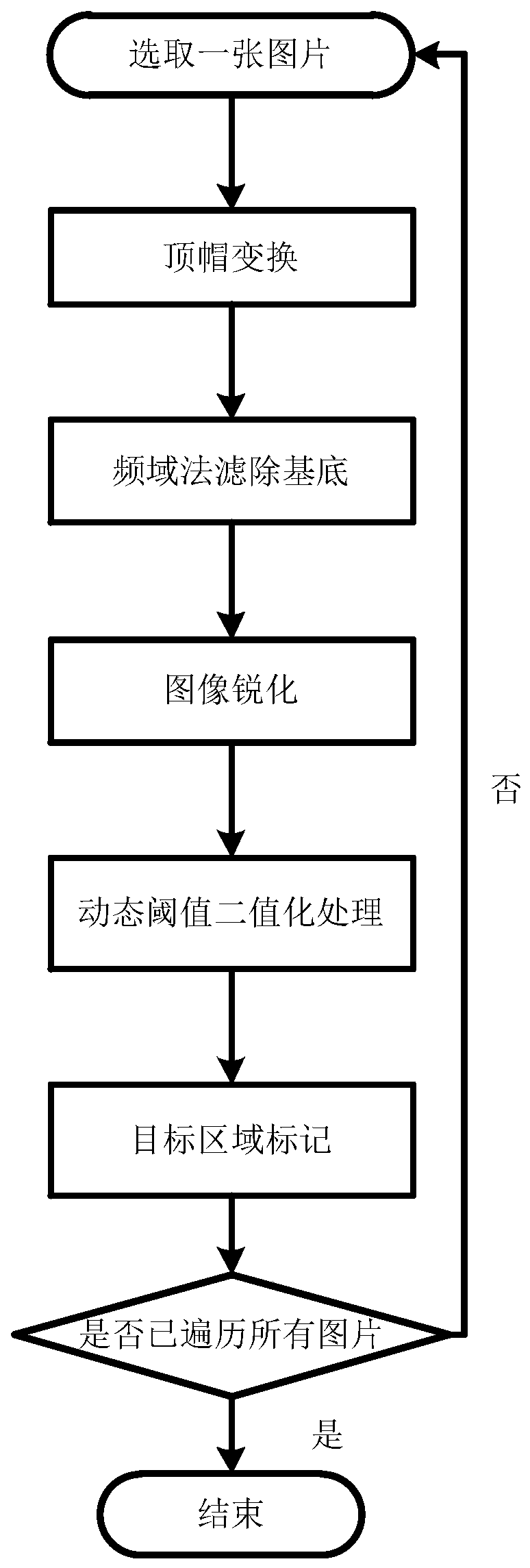

[0053] like figure 1 As shown, the present invention provides a method for measuring the dispersion degree of metal atoms of a supported catalyst by utilizing electron microscope characterization, image program identification and information statistics, which specifically includes the following steps:

[0054] (1) Use a transmission electron microscope (TEM) to obtain pictures of the metal catalyst; before using the transmission electron microscope, select the parameters of the scanning transmission electron beam (STEM-HAADF) and set the parameters of the imaging sensor: the parameters of the scanning transmission electron beam include the acceleration voltage , aperture size and camera constant, etc.; the parameters of the imaging sensor include signal gain, signal baseline compensation and image contrast display mode, etc.;

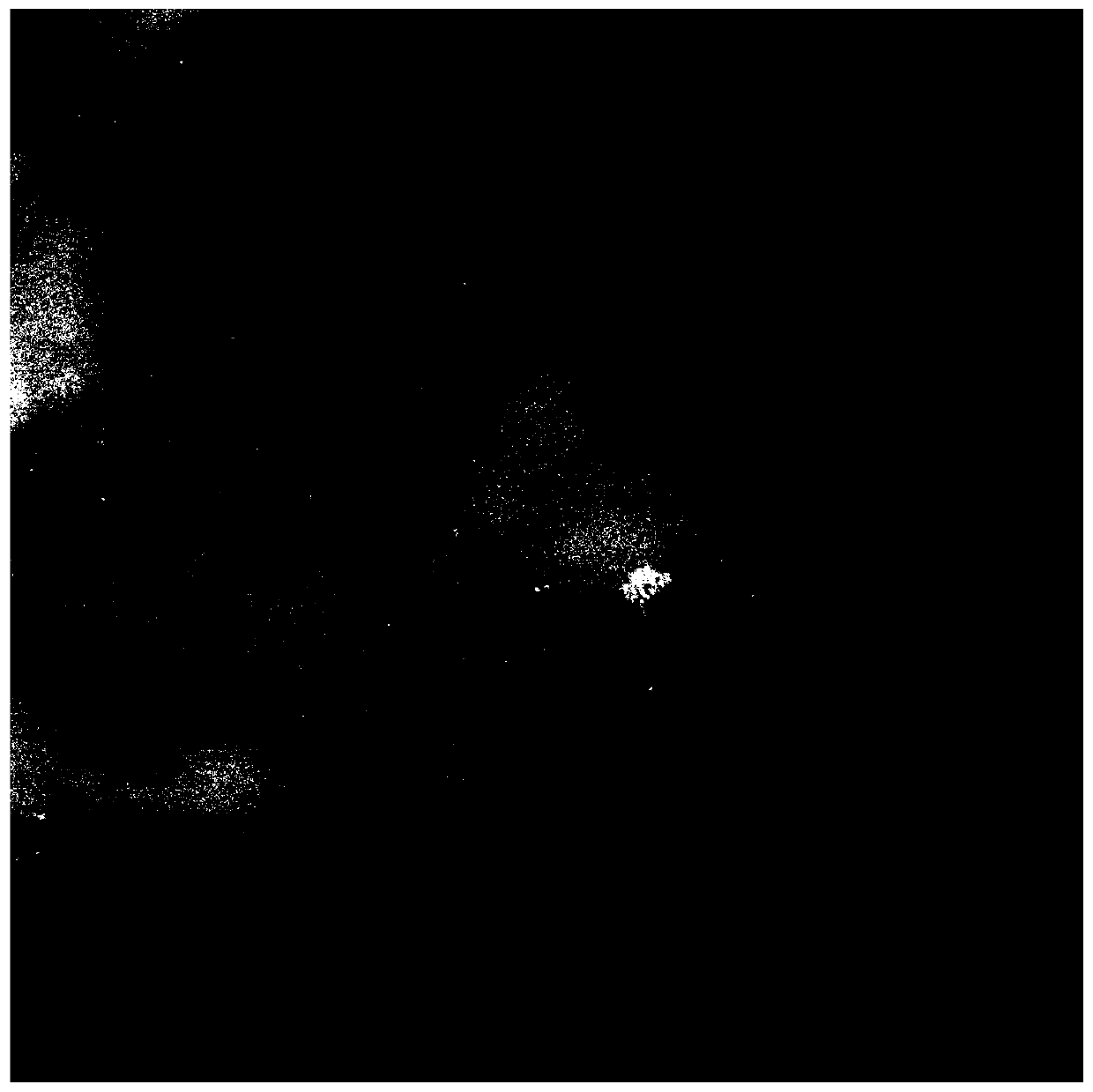

[0055] (2) Metal particle identification processing, followed by top hat transformation, frequency domain method to filter out the base, image sharpeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com