Cement nano-suspension concrete early strength agent and preparation method thereof

A nano-suspension, concrete technology, applied in the field of concrete early strength agent, can solve the problems of easy cracking of concrete, no benefit in later strength, energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

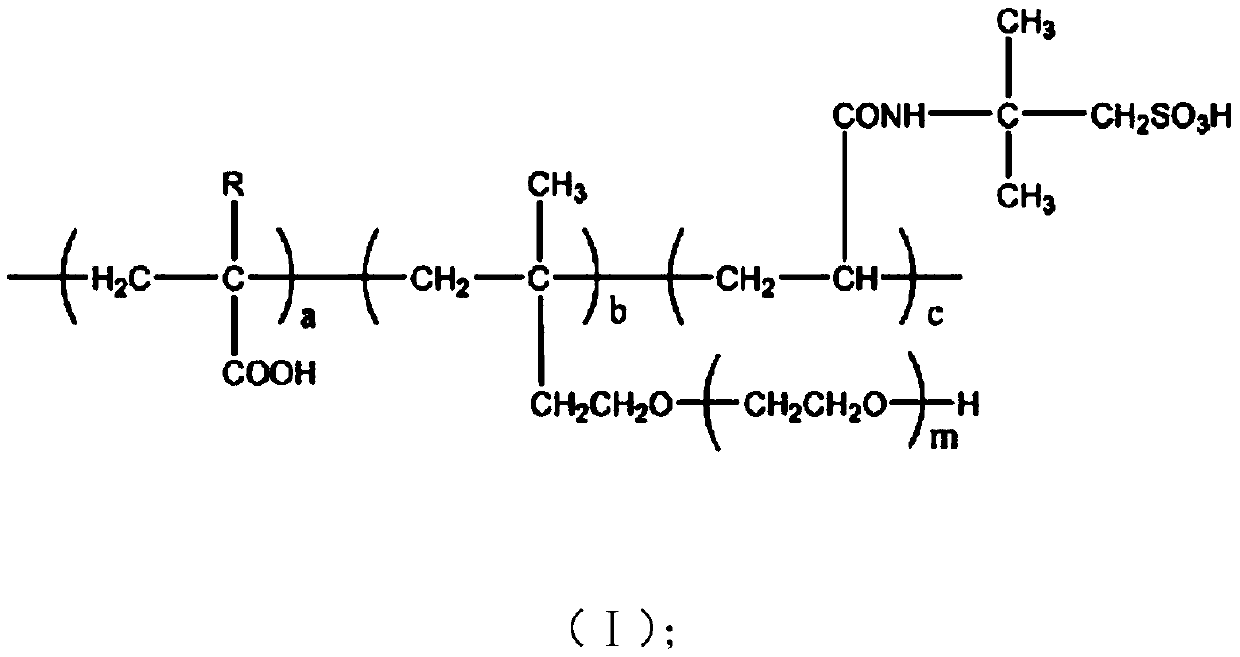

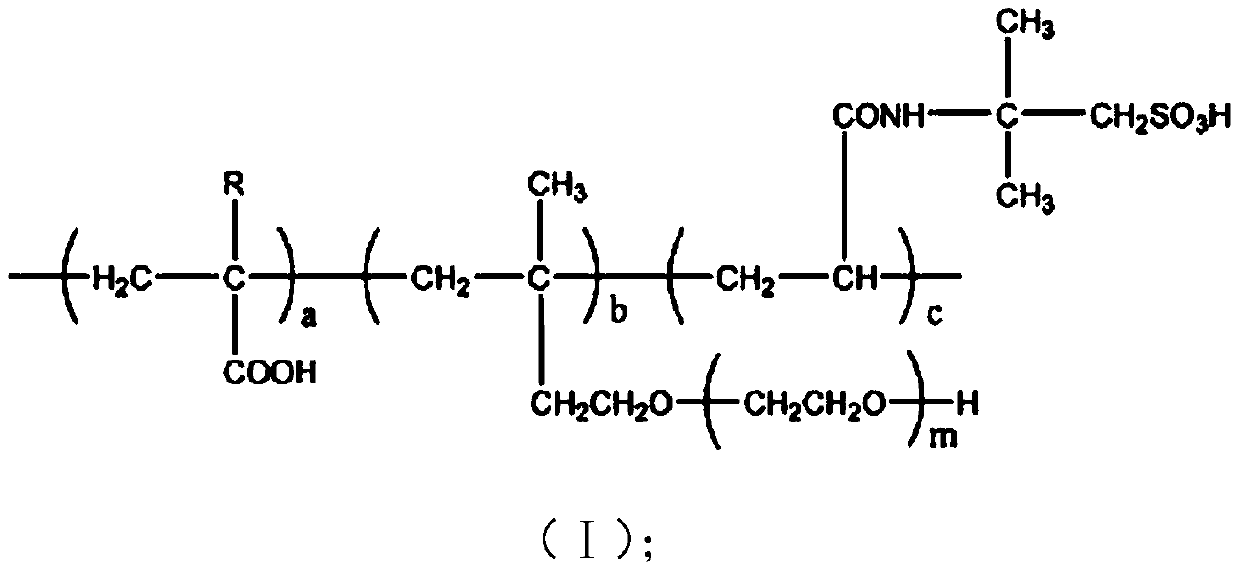

Method used

Image

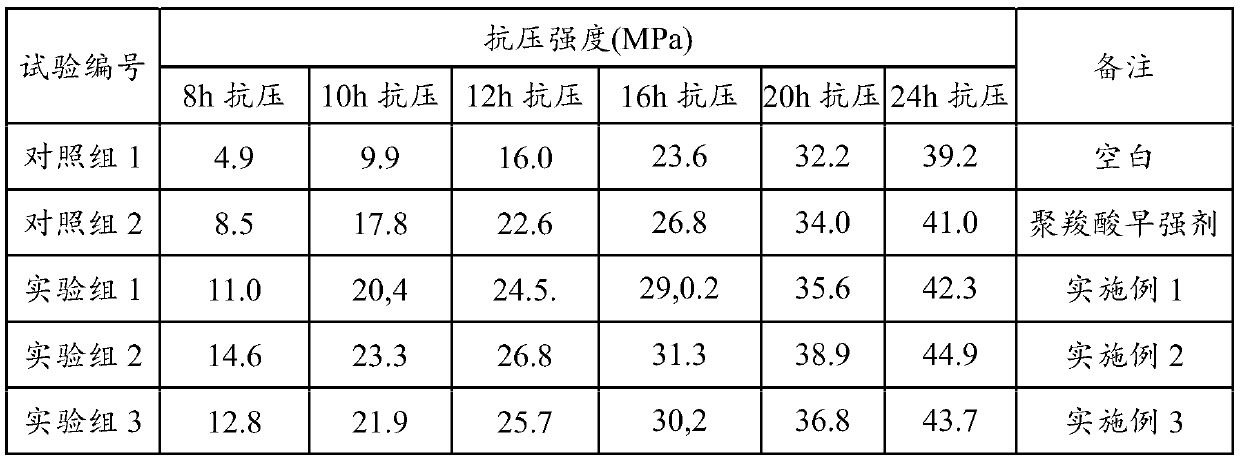

Examples

Embodiment 1

[0026] An embodiment of the cement nano-suspension concrete early-strength agent of the present invention, the cement nano-suspension concrete early-strength agent described in this embodiment comprises the following components by weight: 2 parts of nano-portland cement, polycarboxylic acid 25 parts of dispersants and 10 parts of polyvinylpyrrolidone (PVP); the solid content of the polycarboxylate water reducer is 25%; the nano Portland cement is ground by PI, PII Portland cement The clinker is mainly composed of calcium silicate crystals with a particle size ranging from 400nm to 900nm.

[0027] The preparation method of cement nano-suspension concrete early strength agent of the present invention, comprises the following steps:

[0028] (1) In a 500ml three-necked flask, add metered polycarboxylic acid dispersant and metered PVP, stir to fully dissolve PVP, and use sodium hydroxide (or potassium hydroxide, calcium hydroxide, three Ethylamine, triethanolamine, triisoethanola...

Embodiment 2

[0031] An embodiment of the cement nano-suspension concrete early-strength agent of the present invention, the cement nano-suspension concrete early-strength agent described in this embodiment comprises the following components by weight: 6 parts of nano-portland cement, polycarboxylic acid 40 parts of dispersants and 16 parts of polyvinylpyrrolidone (PVP); the solid content of the polycarboxylate water reducer is 40%; the nano Portland cement is ground by PI, PII Portland cement The clinker is mainly composed of calcium silicate crystals with a particle size ranging from 400nm to 900nm.

[0032] The preparation method of cement nano-suspension concrete early strength agent of the present invention, comprises the following steps:

[0033] (1) In a 500ml three-necked flask, add metered polycarboxylic acid dispersant and metered PVP, stir to fully dissolve PVP, and use sodium hydroxide (or potassium hydroxide, calcium hydroxide, three Ethylamine, triethanolamine, triisoethanola...

Embodiment 3

[0036] An embodiment of the cement nano-suspension concrete early-strength agent of the present invention, the cement nano-suspension concrete early-strength agent described in this embodiment comprises the following components by weight: 4 parts of nano-portland cement, polycarboxylic acid 32 parts of dispersants and 13 parts of polyvinylpyrrolidone (PVP); the solid content of the polycarboxylate water reducer is 32%; the nano Portland cement is ground by PI, PII Portland cement The clinker is mainly composed of calcium silicate crystals with a particle size ranging from 400nm to 900nm.

[0037] The preparation method of cement nano-suspension concrete early strength agent of the present invention, comprises the following steps:

[0038] (1) In a 500ml three-necked flask, add the metered polycarboxylate water reducer PCE and the metered PVP, stir to make the PVP fully dissolve, as the bottom material of the flask, use sodium hydroxide (or potassium hydroxide, calcium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com