Crystal form B of flunarizine hydrochloride and preparation method thereof

A technology of flunarizine hydrochloride and its crystal form, which is applied in the field of flunarizine hydrochloride crystal form B and its preparation, can solve problems not involved in polymorph research, etc., and achieve favorable storage, simple preparation method, and hygroscopicity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

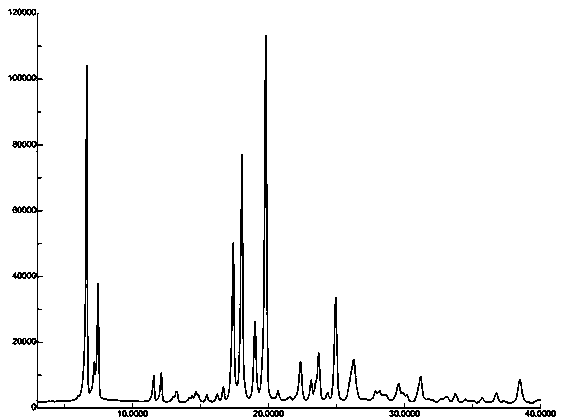

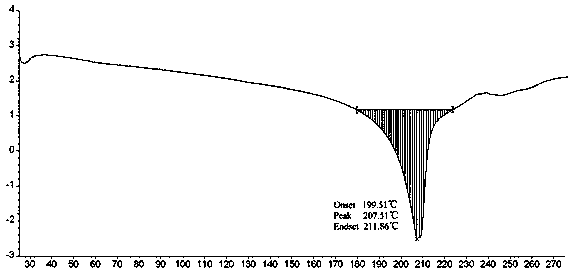

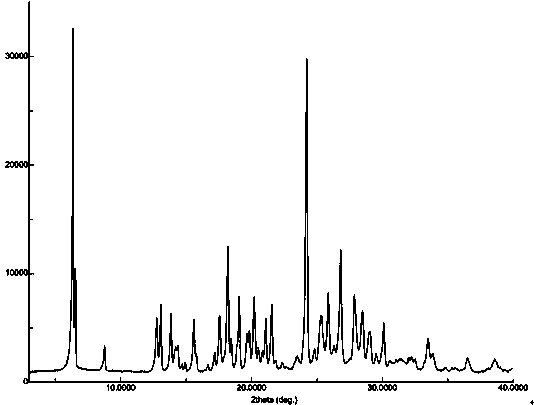

Image

Examples

Embodiment 1

[0036] Put 10 g of flunarizine hydrochloride into 330 g of acetonitrile aqueous solution (mass ratio, acetonitrile: water = 4:1), stir continuously at 65°C for about 40 min until dissolved; add activated carbon, stir for 40 min to decolorize, and filter with suction ; Move the filtrate into a crystallizer at 50°C and keep it warm; add 330 g of acetonitrile to the crystallizer at a constant speed within 1 hour, and continue to stir at a constant temperature for 2 hours after the overall solution is obviously turbid; then slowly cool the system down to 35°C within 3 hours , and stirred at a constant temperature for 4 h at the end of cooling; then quickly cooled the system to 10°C within 30 min, and stirred at a constant temperature for 1 h at the end of cooling; filtered with suction, washed the filter cake with 70% acetonitrile aqueous solution; collected the filter cake, and dried it at 65°C Vacuum (0.08MPa) dried for 12 h, collected the product, and obtained 8.56 g of white gr...

Embodiment 2

[0038]Put 10 g of flunarizine hydrochloride into 100 g of acetonitrile aqueous solution (mass ratio, acetonitrile: water = 7:3), stir continuously at 70°C for about 1 h until dissolved; add activated carbon, stir for decolorization for 60 min, and filter with suction ; Move the filtrate into a crystallizer at 55°C and keep it warm; add 300 g of acetonitrile to the crystallizer at a constant speed within 30 min, and continue to stir at a constant temperature for 1 h after the overall solution is obviously turbid; then slowly cool the system down to 45°C within 4 h. ℃, and stirred at a constant temperature for 2 h at the end of cooling; then quickly cooled the system to 5 °C within 45 min, and stirred at a constant temperature for 3 h at the end of cooling; filtered with suction, and washed the filter cake with 80% acetonitrile aqueous solution; The product was dried under vacuum (0.1MPa) for 15 h, and the product was collected to obtain 9.23 g of white granular flunarizine hydro...

Embodiment 3

[0040] Put 10 g of flunarizine hydrochloride into 180 g of acetonitrile aqueous solution (mass ratio, acetonitrile: water = 3:1), stir continuously at 65°C for about 40 min until dissolved; add activated carbon, stir for 50 min to decolorize, and filter with suction ; Move the filtrate into a crystallizer at 52°C and keep it warm; add 270 g of acetonitrile to the crystallizer at a uniform speed within 45 minutes, and continue to stir at a constant temperature for 90 minutes after the overall solution is obviously turbid; then slowly cool the system to 40 within 2 hours. ℃, and stirred at a constant temperature for 2 h at the end of cooling; then quickly cooled the system to 6°C within 40 min, and stirred at a constant temperature for 30 min at the end of cooling; filtered with suction, and washed the filter cake with 75% acetonitrile aqueous solution; The product was dried under vacuum (0.08 MPa) for 15 h, and the product was collected to obtain 8.69 g of white granular flunari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com