Phase-change interior wall paint composite material

A composite material and interior wall paint technology, applied in the field of interior wall paint, to achieve the effects of stable performance, high heat transfer efficiency, and reduced temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

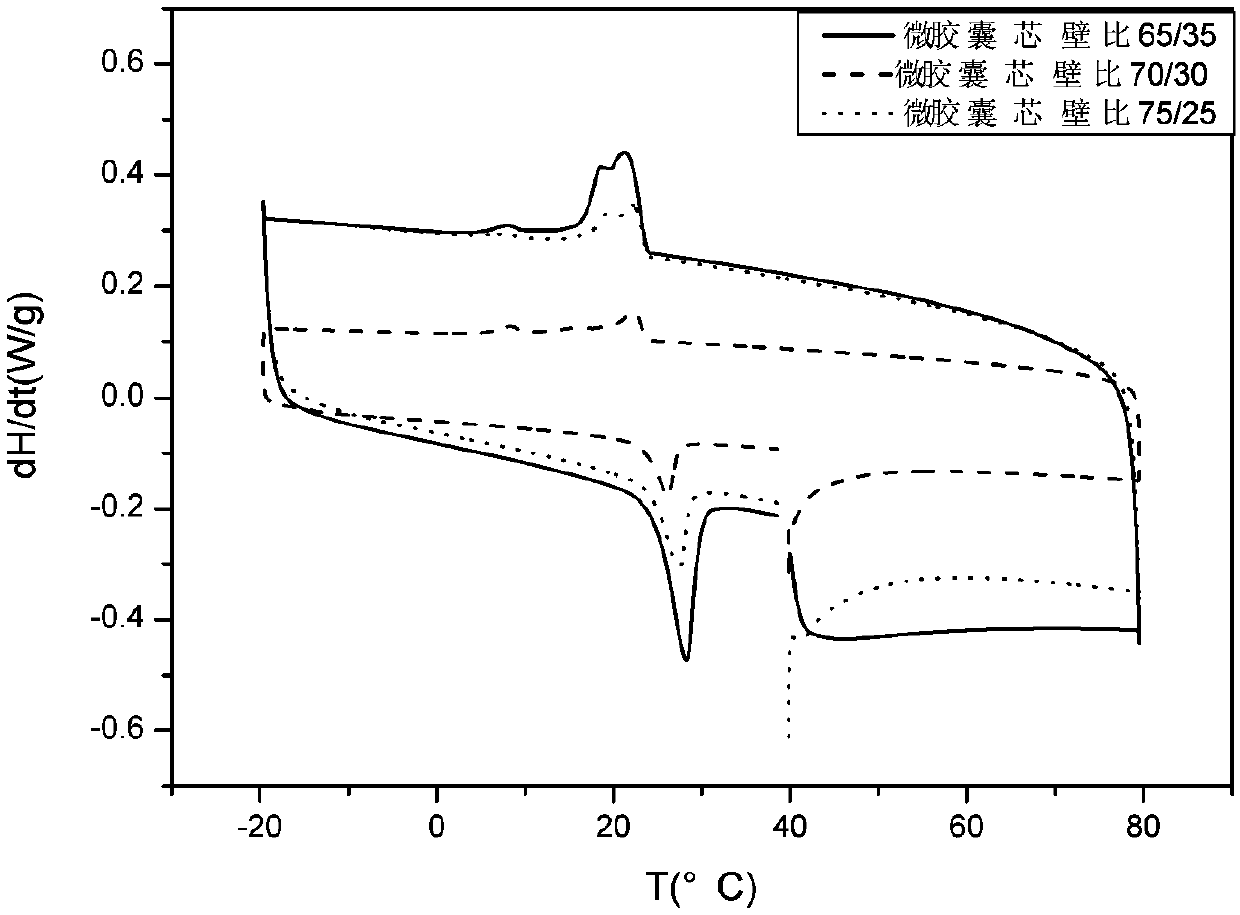

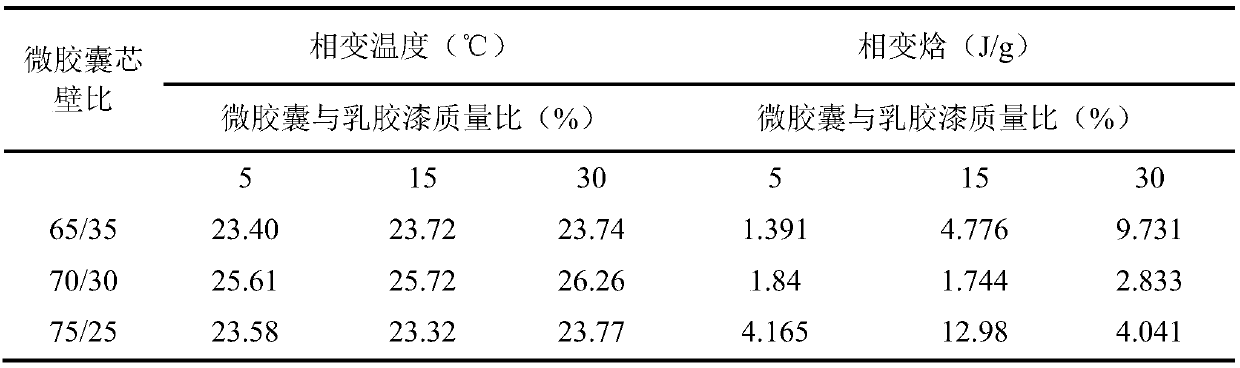

Embodiment 1

[0028] A kind of phase-change interior wall paint composite material, described interior wall paint composite material comprises latex paint and phase change microcapsule, and the total weight of described interior wall paint composite material is 100%, the phase change microcapsule The weight percentage is 5%. In the phase change microcapsules, the core material is octadecane microspheres, the wall material is urea-formaldehyde resin (the molar ratio of urea and formaldehyde is 2:1), and the core material and the wall material The mass ratio is 65:35.

Embodiment 2

[0030] A kind of phase-change interior wall paint composite material, described interior wall paint composite material comprises latex paint and phase change microcapsule, and the total weight of described interior wall paint composite material is 100%, the phase change microcapsule The weight percentage is 5%. In the phase change microcapsules, the core material is octadecane microspheres, the wall material is urea-formaldehyde resin (the molar ratio of urea and formaldehyde is 2:1), and the core material and the wall material The mass ratio is 70:30.

Embodiment 3

[0032] A kind of phase-change interior wall paint composite material, described interior wall paint composite material comprises latex paint and phase change microcapsule, and the total weight of described interior wall paint composite material is 100%, the phase change microcapsule The weight percentage is 5%. In the phase change microcapsules, the core material is octadecane microspheres, the wall material is urea-formaldehyde resin (the molar ratio of urea and formaldehyde is 2:1), and the core material and the wall material The mass ratio is 75:25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition peak temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com