Negative-pressure smokeless barrel type incineration system

A cartridge type, negative pressure technology, applied in the field of negative pressure smokeless cartridge incineration system, can solve problems such as inability to clear, increase in tail gas volume, and difficult disposal of radioactive waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

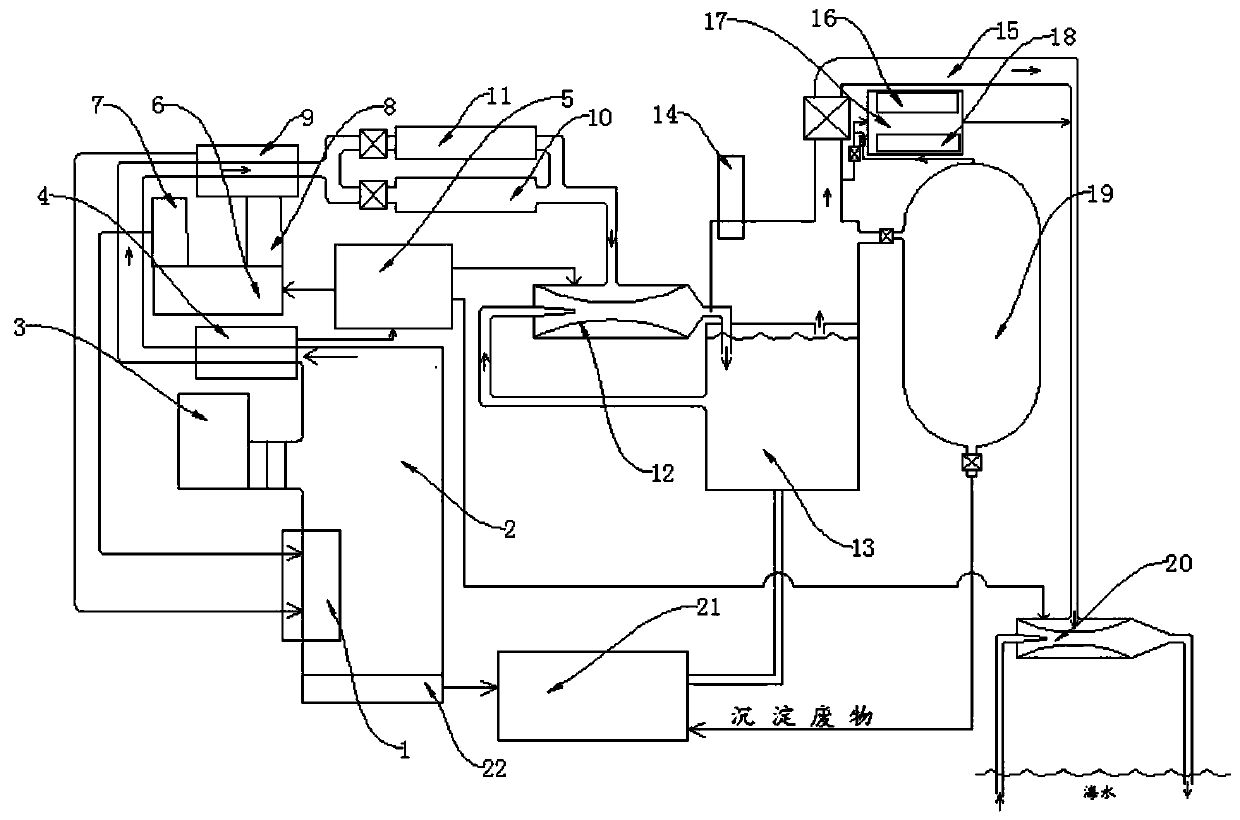

[0014] Such as figure 1 As shown, the negative pressure smokeless cylinder type incineration system in this embodiment includes a hydrogen-oxygen igniter 1, an incinerator 2, a feed port 3, a heat exchanger 4, a waste heat generator 5, a water ionizer 6, and an ionized hydrogen gas collection Device 7, ionized oxygen collector 8, oxygen / air heat exchanger 9, first aerosol filter 10, second aerosol filter 11, water jet negative pressure generator 12, water tank 13, first radioactive detector 14. Gas discharge channel 15, compressed and retained gas storage tank 19, secondary washing negative pressure generator 20, waste solidification chamber 21 and furnace ash chamber 22, wherein:

[0015] The hydrogen-oxygen igniter 1 is connected with the bottom of the incinerator 2, the ash chamber 22 is connected with the bottom of the incinerator 2, and the ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com