Modified polyethylene terephthalate (PET) film for lithium battery flexible packaging film

A flexible packaging film and lithium battery technology, applied in the field of modified polyester, can solve the problems of poor gas barrier properties and gas barrier properties of PET, and achieve the effects of protecting the structure, uniform particle size, and accelerated water sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

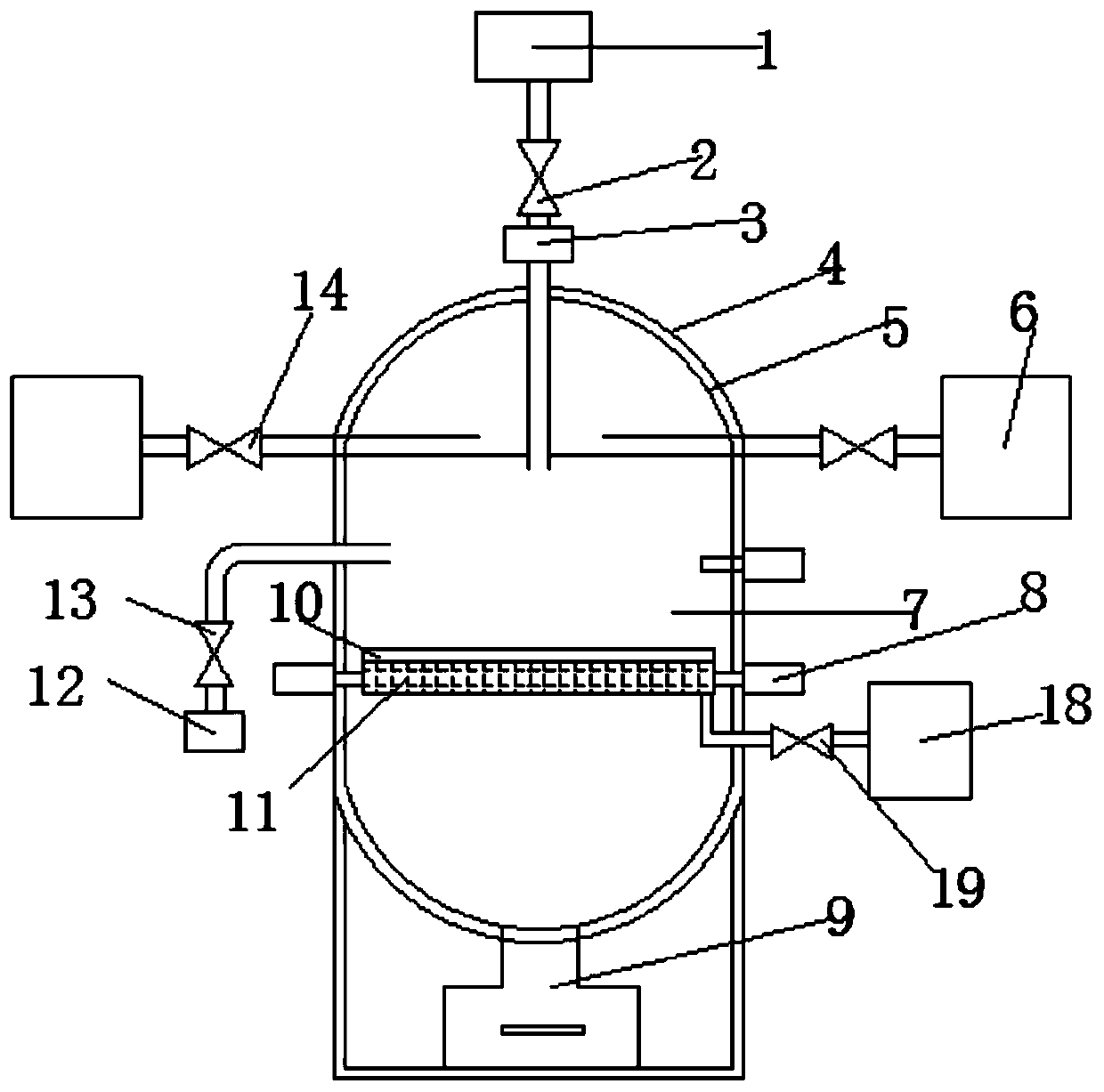

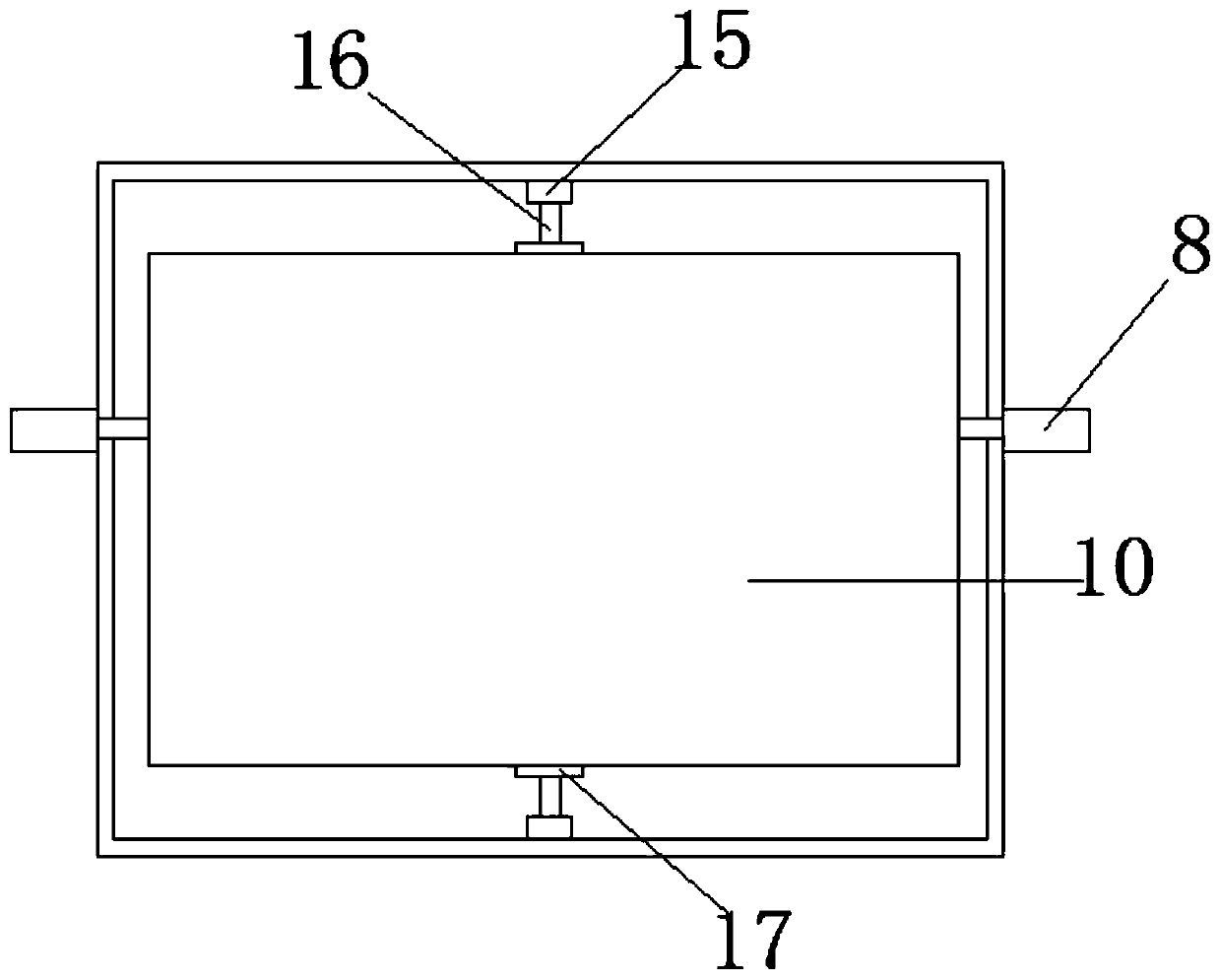

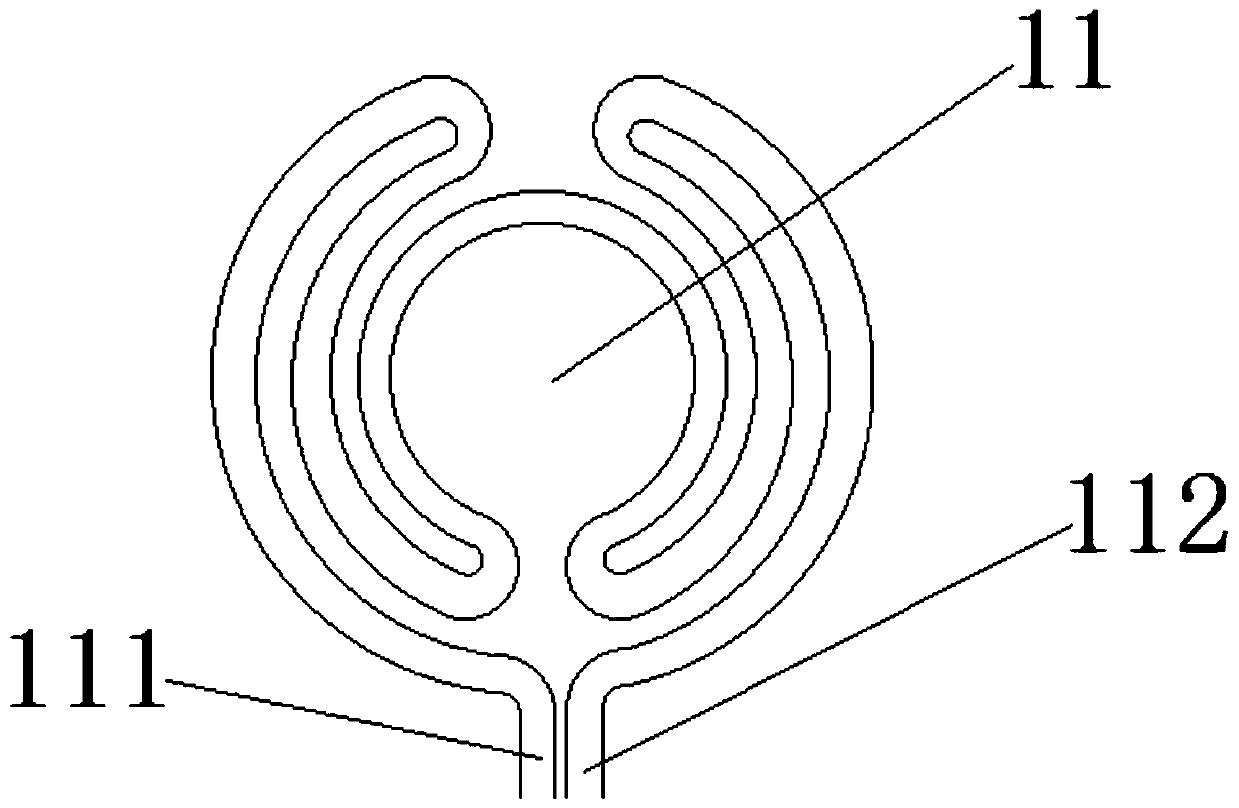

[0041] see Figure 1-3 Shown, a kind of modified PET film that is used for lithium battery flexible packaging film, this modified PET film is made up of the following components in parts by weight: 71.5 parts of terephthalic acid, 130 parts of ethylene glycol, nanometer montmorillonite 12.4 parts, 5.4 parts of polyethylene glycol, 4.8 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane;

[0042] Modified PET film preparation method:

[0043] S1. Put nano-montmorillonite, dispersant and coupling agent, terephthalic acid and ethylene glycol into the reactor. The temperature of the reactor is 195.5°C and the pressure is 0.34MPa. Terephthalic acid and ethylene glycol ester Chemical reaction obtains polyethylene terephthalate with low degree of polymerization;

[0044] S2. When the temperature of the reactor is 256°C and the pressure is 32Pa, polyethylene terephthalate with a low degree of polymerization undergoes a polycondensation reaction in the nano-montmorillonite. Durin...

Embodiment 2

[0056] see Figure 1-3 Shown, a kind of modified PET film that is used for lithium battery flexible packaging film, this modified PET film is made up of the following components in parts by weight: 73.5 parts of terephthalic acid, 136.5 parts of ethylene glycol, nanometer montmorillonite 21.6 parts, 1.6 parts of polyethylene glycol, 1.8 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane;

[0057] Modified PET film preparation method:

[0058] S1. Put nano-montmorillonite, dispersant and coupling agent, terephthalic acid and ethylene glycol into the reactor. The temperature of the reactor is 195.6°C and the pressure is 0.36MPa. Chemical reaction obtains polyethylene terephthalate with low degree of polymerization;

[0059] S2. When the temperature of the reactor is 264°C and the pressure is 30.5Pa, the poly(ethylene terephthalate) with a low degree of polymerization undergoes a polycondensation reaction in the nano-montmorillonite. During the polycondensation reaction, t...

Embodiment 3

[0070] see Figure 1-3 Shown, a kind of modified PET film that is used for lithium battery flexible packaging film, this modified PET film is made up of the following components in parts by weight: 78.5 parts of terephthalic acid, 148.5 parts of ethylene glycol, nanometer montmorillonite 20.5 parts, 8.5 parts of polyethylene glycol, 11.5 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane;

[0071] Modified PET film preparation method:

[0072] S1. Put nano-montmorillonite, dispersant and coupling agent, terephthalic acid and ethylene glycol into the reactor. The temperature of the reactor is 195.5°C and the pressure is 0.38MPa. Terephthalic acid and ethylene glycol ester Chemical reaction obtains polyethylene terephthalate with low degree of polymerization;

[0073]S2. When the temperature of the reactor is 262.5°C and the pressure is 35Pa, polyethylene terephthalate with a low degree of polymerization undergoes a polycondensation reaction in the nano-montmorillonite. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com