Hemp fiber mattress and production method thereof

A hemp fiber and bed core technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of high environmental pollution, hemp fiber spinning, poor acupuncture performance, rough and hard hemp fiber, etc., and achieve high melting point , low cost, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

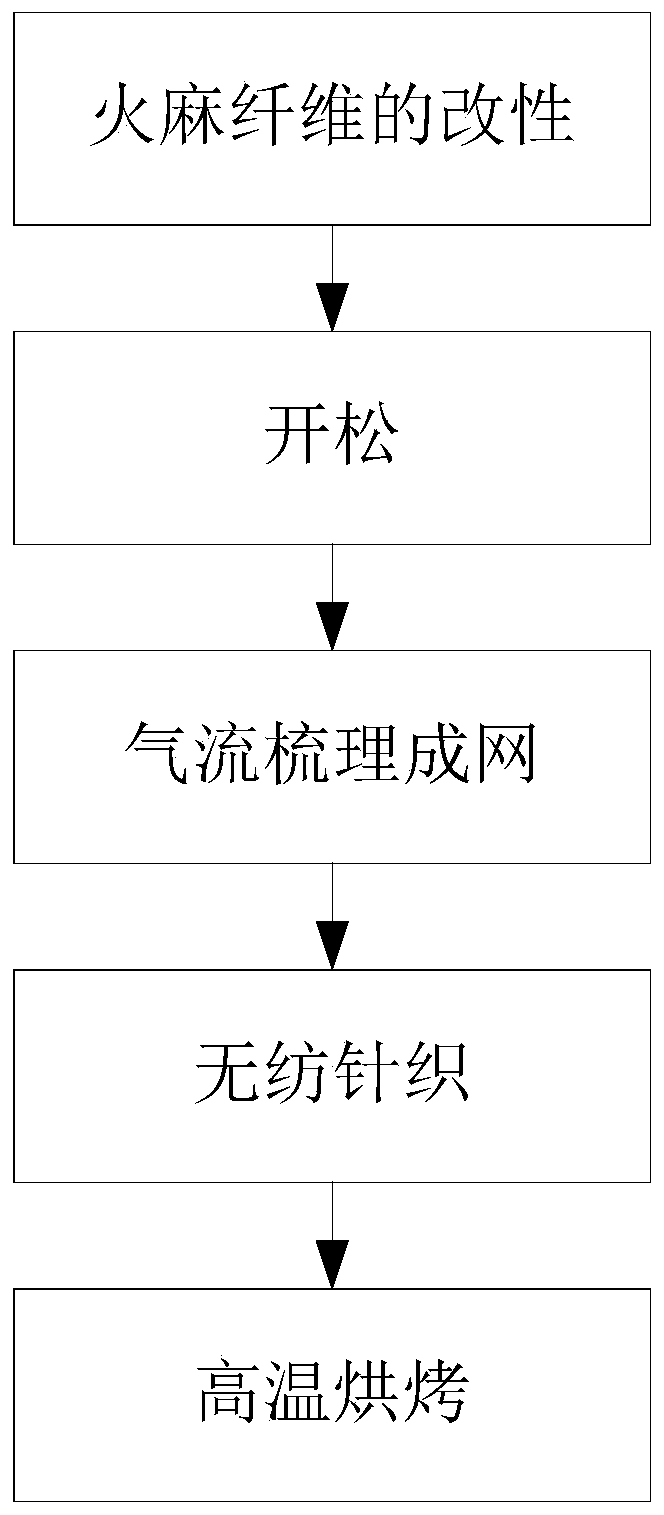

[0029] Such as figure 1 As shown, what the present invention proposes is a kind of preparation method of hemp fiber bed core with high quality and low price. It includes five main steps of modifying hemp fiber, opening, air-flow combing, non-woven knitting, and high-temperature baking. The present invention will be described in detail below in conjunction with these five steps.

[0030] (1) Modification of hemp fiber:

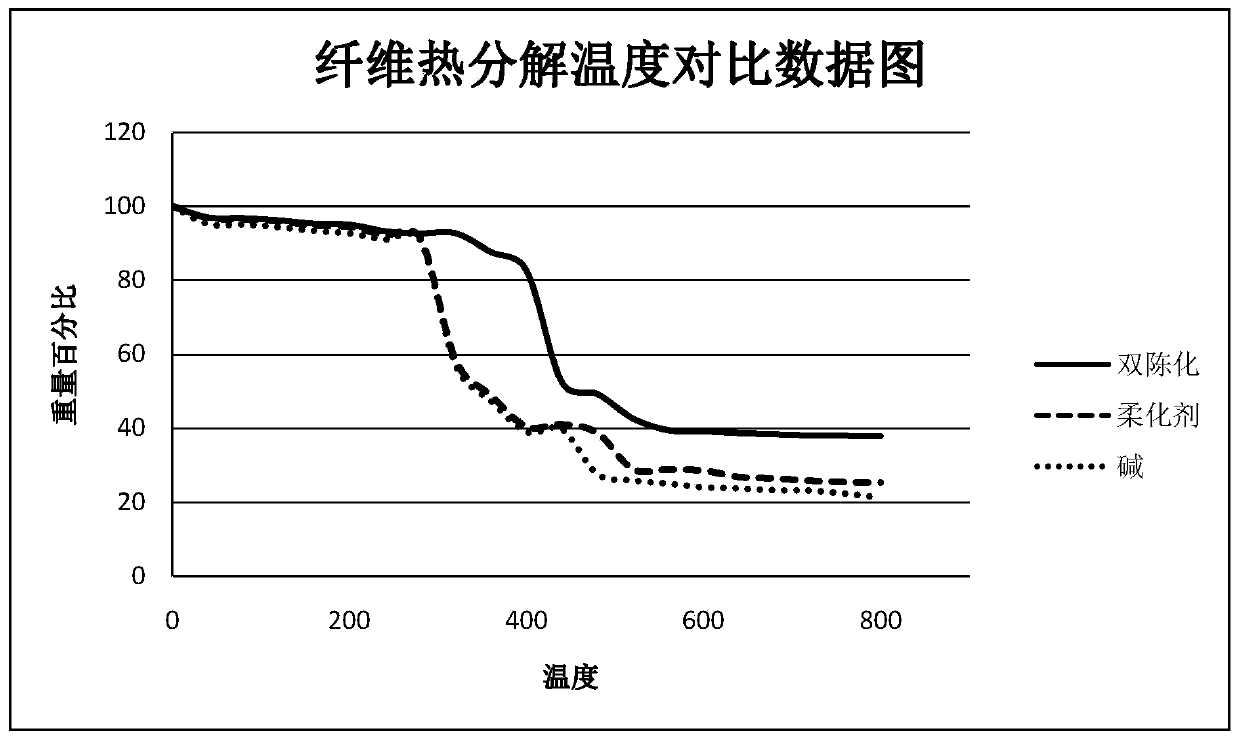

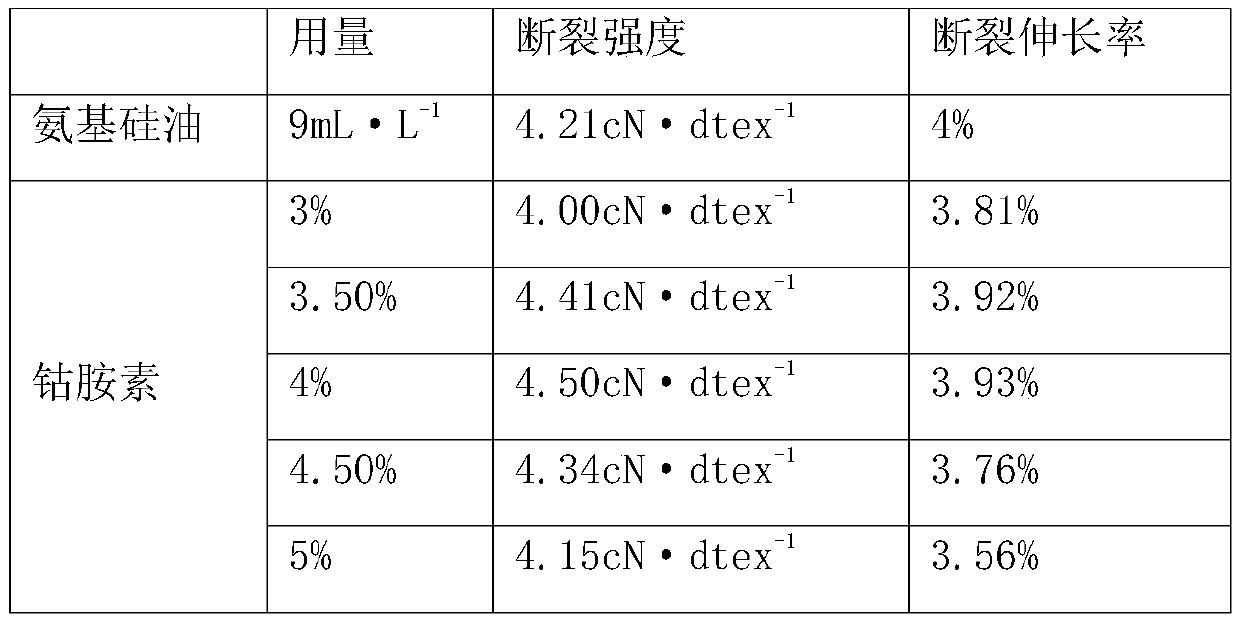

[0031] At present, there are many research reports on the spinnability modification of hemp fibers in natural fibers. The modification of natural hemp fibers mainly includes biological modification technology, chemical modification technology, and surface physical and chemical modification technology. The deficiencies of the fiber itself can improve dyeing, spinnability, wearability, etc. After searching and combining the technical content of the present invention, the inventor proposes the paper "Study on the Spinnability Modification of Nettle Fiber" writt...

Embodiment 1

[0053] The inventive method comprises:

[0054] (1) Hemp fiber modification

[0055] With 8 parts of modifying agent 23%, then add glucose 0.8%, peptone 0.8%, all the other are water, described modifying agent Acidobacillus cellulolyticum, Micromonospora and Gluconacetobacter, its addition ratio is 2 :2:3; at the same time add 3% cobalamin. Immerse 75 parts of hemp fiber in the modifier, modify it at 38°C for 15 hours, add it to the vacuum reactor, and carry out vacuum impregnation at 40°C for 20 minutes; then take it out, filter it, and use deionized water Surface wash hemp fibers to neutral.

[0056] (2) Opening: the modified hemp fibers are combed and shortened into short hemp fibers, and then the hemp fibers are sent to the opening feeder for opening;

[0057] (3) Airflow combing into a net: the short hemp fibers after opening are evenly arranged down from the drum groove through the airflow, and the short hemp fibers after opening are evenly arranged by the airflow to ...

Embodiment 2

[0062] The inventive method is:

[0063] (1) Hemp fiber modification

[0064] Use 5 parts of modifying agent 15%, then add glucose 0.5%, peptone 0.5%, and the rest is the proportion of water, the modifying agent Acidobacillus cellulolyticus, Micromonospora and Gluconacetobacter, which add The ratio is 1:3:2; at the same time, add 5% cobalamin. Immerse 80 parts of hemp fiber in the modifier, modify it at 35°C for 20 hours, add it to the vacuum reactor, and carry out vacuum impregnation at 45°C for 30 minutes; then take it out, filter it, and use deionized water Surface wash hemp fibers to neutral.

[0065] (2) Opening: the modified hemp fibers are combed and shortened into short hemp fibers, and then the hemp fibers are sent to the opening feeder for opening;

[0066] (3) Airflow combing into a net: the short hemp fibers after opening are evenly arranged down from the drum groove through the airflow, and the short hemp fibers after opening are evenly arranged by the airflow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com