Machining method of 3D product and machining device

A processing method and processing device technology, applied in the field of grinding processing, can solve the problems of easy wear and service life of processing tools, high impact of surface roughness, unfavorable heat dissipation and cooling, etc., so as to save labor costs, realize automatic processing, save The effect of R&D spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

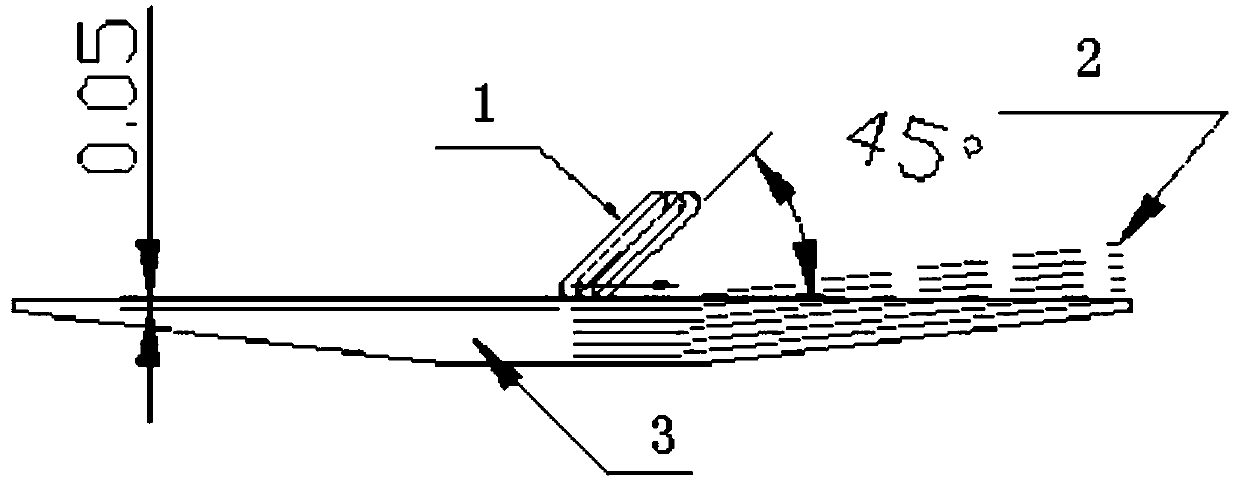

[0033] A processing device for 3D products includes a CNC numerical control machine tool, a rotating base and a product fixing fixture. The CNC numerical control machine tool includes a workbench and a spindle for processing, and the spindle is provided with a processing tool 1 for processing a workpiece 3 to be processed.

[0034] The rotating base includes a body, a motor and a vertically arranged output shaft. The body is arranged on the workbench. The motor is arranged on the body and connected to one end of the output shaft to provide rotational power. The output shaft The other end is connected to the product fixing jig, and the product fixing jig is driven to rotate through the combination of the motor and the output shaft.

[0035] The product positioning fixture also includes a pneumatic gripper positioned directly below the processing tool 1 on the main shaft, and the pneumatic gripper is used for positioning and clamping the workpiece 3 to be processed; the processi...

Embodiment 2- Embodiment 9

[0049] The processing device of embodiment 2-embodiment 9 is the same as embodiment 1.

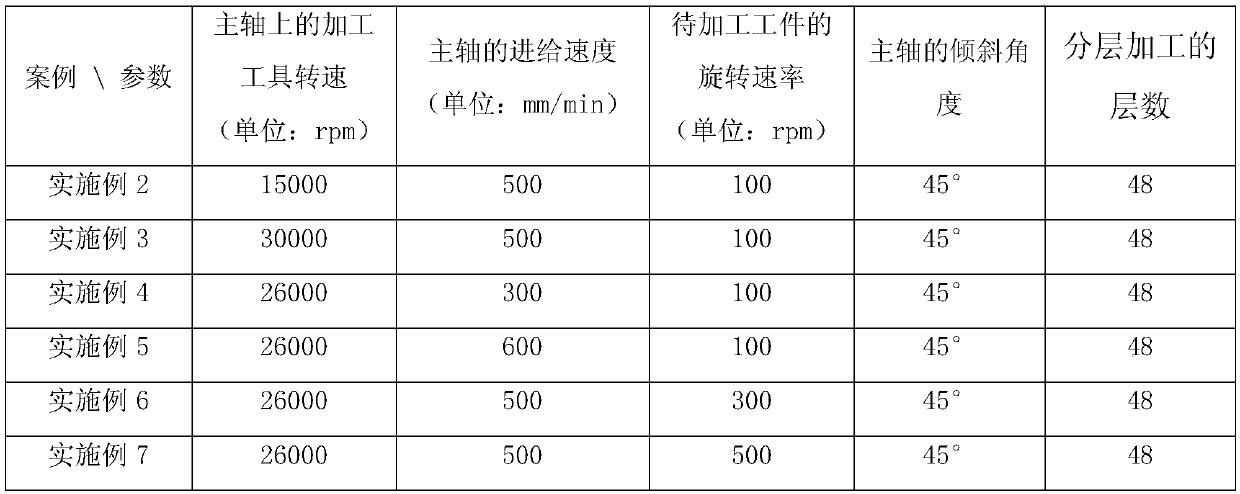

[0050] A processing method for 3D products, the inclination angle of the main shaft is set to 45°, and the total processing depth of the ceramic product is 2.4 mm; wherein the embodiment 2-embodiment 7 sets the cutting amount of the main shaft in the vertical direction to be 0.05 mm, layered The quantity of processing is 48 layers; Embodiment 8 sets the cutting amount of the main shaft in the vertical direction to be 0.1mm, and the number of layered processing is 24 layers; Embodiment 9 sets the cutting amount of the main shaft in the vertical direction to be 0.04mm, The number of layered processing is 60 layers; the parameter settings of embodiment 2-embodiment 9 are detailed in Table 1:

[0051] Table 1 embodiment 2-embodiment 9 parameter setting statistical table

[0052]

[0053]

[0054] The processing effect of embodiment 2-embodiment 9 is shown in table 3.

Embodiment 10

[0056] The processing device of embodiment 10 is the same as embodiment 1.

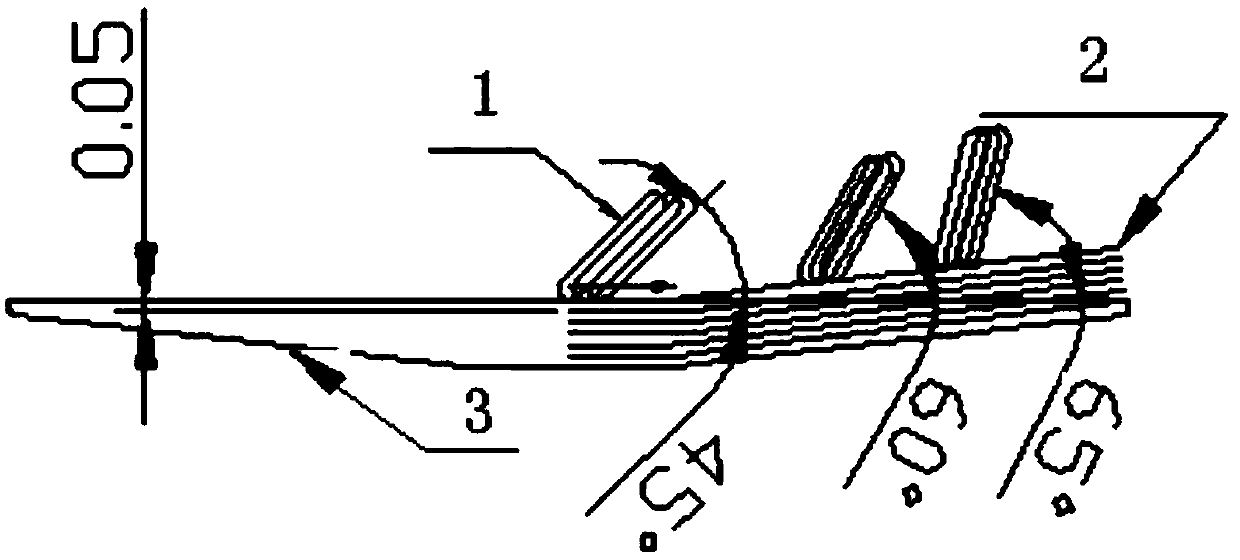

[0057] A processing method for 3D products, the total processing depth of the ceramic product is 2.4mm, the cutting amount of the spindle in the vertical direction is 0.05mm, and the number of layered processing is 48 layers; the processing tool speed on the spindle is 26000rpm; The feed speed of the main shaft is 500mm / min; the rotation rate of the workpiece driven by the rotating base is 100rpm; in this embodiment: the inclination angle of the main shaft changes continuously during the processing; correspondingly, the The angle between the processing tool and the surface to be processed of the workpiece is also continuously changing, see figure 2 (showing three states of 45°, 60° and 65° between the processing tool and the surface to be processed of the workpiece to be processed). The change of the inclination angle of the main shaft can make full use of the side of the grinding wheel for grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com