Transparent sports surface layer, preparation method thereof and sports paving material

A kind of sports surface and transparent technology, which is applied in the direction of pavement, building, road, etc., can solve the problems of time-consuming and labor-consuming production, unsightly appearance, adverse effects on the sports performance of sports paving materials, etc., and achieve the effect of good sports performance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

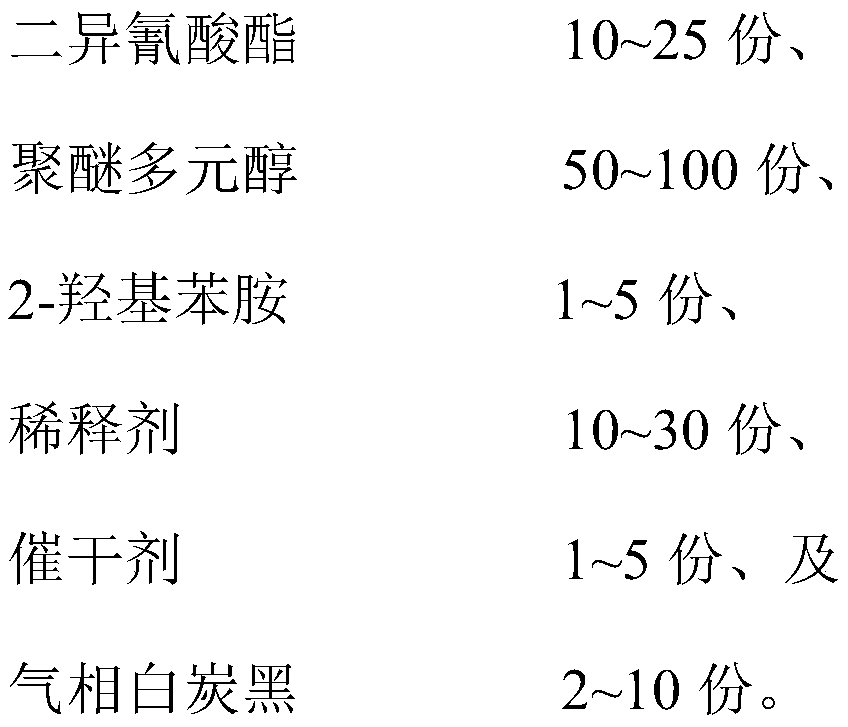

[0034] The preparation method of the above-mentioned transparent sports surface layer comprises the following steps:

[0035] mixing the 2-hydroxyaniline and the polyether polyol, and performing dehydration;

[0036] Then add the diisocyanate to the mixed material after the dehydration treatment to carry out polyaddition reaction; then add the diluent, drier and fumed silica, and stir;

[0037] Lay the mixed material after stirring, and solidify and shape it.

[0038] Instead of directly using polyurethane resin, the matrix resin is prepared by polyaddition of polyether polyol and diisocyanate, and at the same time, the order of adding each raw material is reasonably controlled. First, mix the 2-hydroxyaniline and polyether polyol and carry out The dehydration treatment is conducive to the subsequent full contact reaction with diisocyanate, and the dispersion of fumed silica in the matrix resin, thereby ensuring the physical and chemical properties of the prepared sports surf...

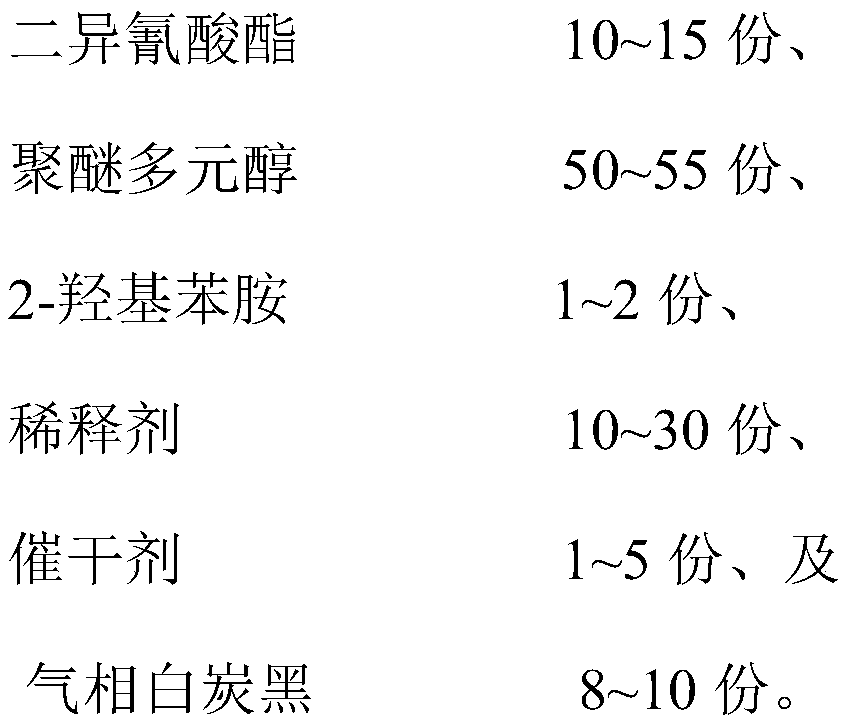

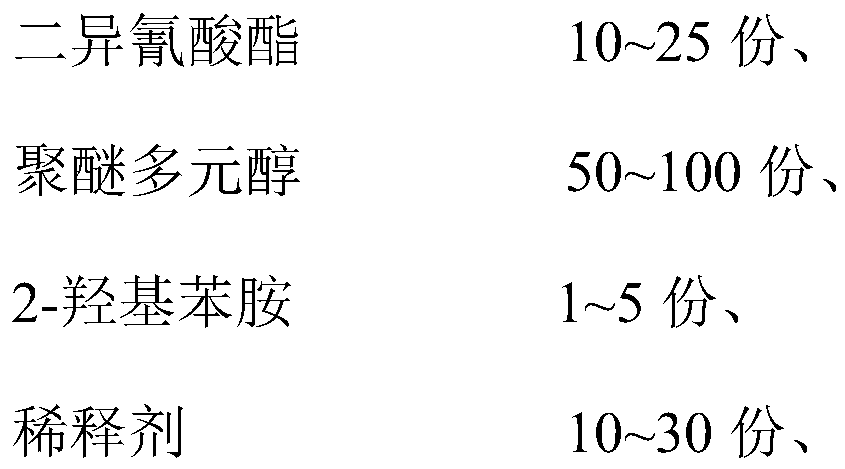

Embodiment 1-5

[0050] Embodiment 1-5 provides 5 kinds of sports paving materials, and its raw material components are as shown in table 1 (parts by weight):

[0051] Table 1

[0052]

[0053]

[0054] The preparation method of above-mentioned sports pavement is as follows:

[0055] (1) Put polyether polyol and 2-hydroxyaniline into the reaction kettle, heat to 100°C, stir and mix, and vacuum dehydrate for 60min;

[0056] (2) The temperature of the material in the reaction kettle is lowered to 80°C, then diisocyanate is added, mixed and stirred, heated and kept at 95°C for 2.5h;

[0057] (3) Cool to ≤50°C, then add diluent, stir for 30 minutes, and cool to room temperature;

[0058] (4) Add drier and fumed silica, stir evenly, and vacuumize for 30 minutes;

[0059](5) Lay out materials, and use runway paving tools or spraying equipment to spread or spray the materials on the bottom film or the designated area and mold on the ground, and then cure and shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com