Plugging agent and preparation method thereof

A technology of plugging agent and curing agent, applied in chemical instruments and methods, drilling composition, etc., can solve problems such as adverse effects of curing strength, effect of monomers, slurry preparation water or drilling fluid that does not have curing effect, etc. , to improve the retention capacity, reduce the free water content and increase the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

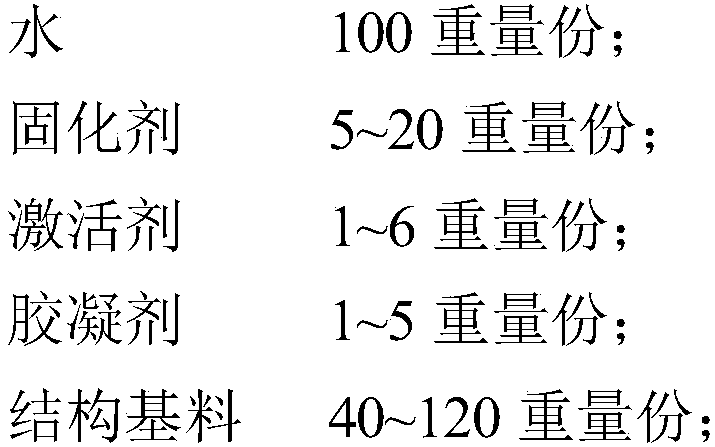

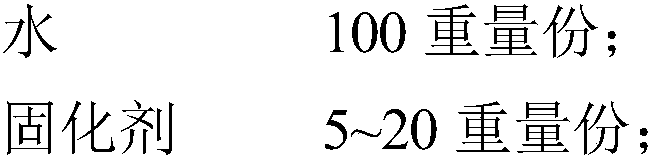

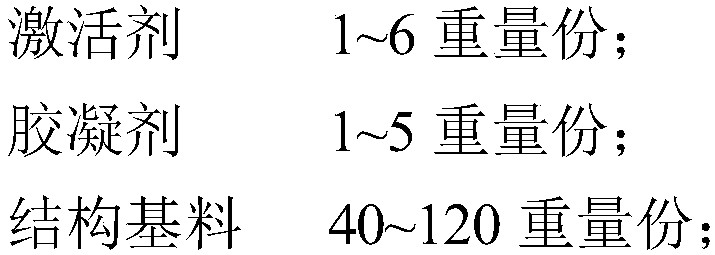

[0043] The present invention also provides a preparation method of the above-mentioned leakage stoppage agent, comprising: S1) mixing 100 parts by weight of water, 5-20 parts by weight of curing agent, 1-6 parts by weight of activator and 1-5 parts by weight of The gelling agent is mixed to obtain a gel; S2) The gel is mixed with 40-120 parts by weight of a structural base material to obtain a plugging agent.

[0044] Wherein, the water, curing agent, activator, gelling agent and structural base material are all the same as above, and will not be repeated here.

[0045] In the present invention, the step S1) specifically includes: mixing water with a curing agent, adding an activator after being completely dissolved, adding a gelling agent after being completely dissolved, and continuing to stir to obtain a gel; The preferred time is 0.5-10 min; the gel is a colorless or white viscous gel; the viscosity of the gel is preferably 100-1000 mPa.s. This step is to use silicate and...

Embodiment 1

[0050] In parts by mass, add 20 parts by mass of sodium silicate, 1 part by mass of sodium hydroxide, and sodium metaaluminate of 3 parts by mass to 100 parts by mass of water to form a viscous gel, then add 40 parts by mass of Blast furnace slag is used as a plugging agent.

Embodiment 2

[0052] In parts by mass, add 10 parts by mass of sodium silicate, 3 parts by mass of sodium hydroxide, and sodium metaaluminate of 4 parts by mass to 100 parts by mass of water to form a viscous gel, then add 50 parts by mass of Blast furnace slag is used as a plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com