A kind of annular space protection liquid and preparation method thereof

A technology of annulus protection fluid and mixed fluid, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. It can solve the problems of accelerated corrosion rate, gas entering the annulus, serious loss, etc., and achieves a sterilization range Wide range, good anti-scaling ability, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

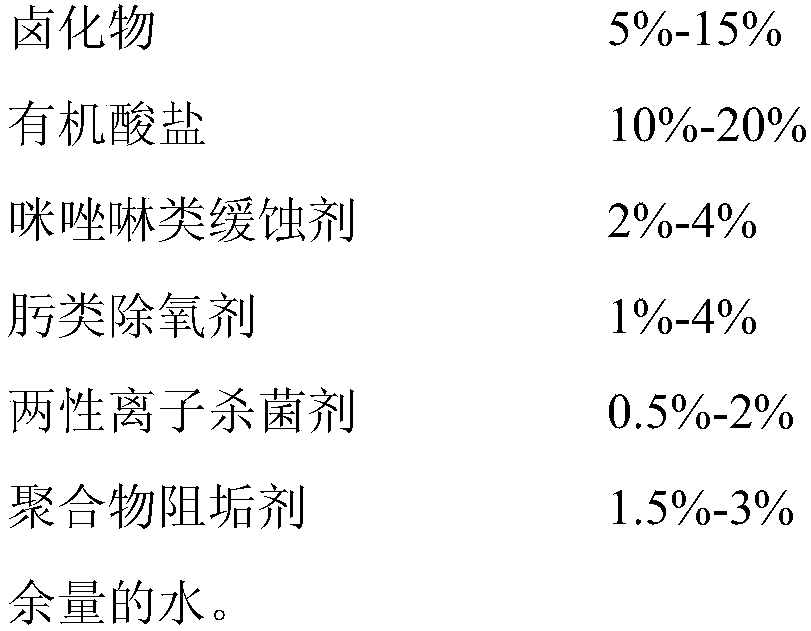

[0028] This embodiment provides an annulus protection solution. In terms of weight percentage, the raw materials for preparing the annulus protection solution include:

[0029]

[0030] This embodiment also provides a preparation method for the above-mentioned annulus protection solution, which includes the following steps:

[0031] Step 1, according to the above ratio, add distilled water and cetyldimethyl (2-sulfite) ethylammonium into the reaction kettle, stir evenly to obtain the mixed solution A1;

[0032] Step 2, adding polyepoxysuccinic acid and dimethyl ketoxime to the mixed solution A1, stirring evenly to obtain the mixed solution B1;

[0033] Step 3: Add imidazoline phosphate, sodium chloride and sodium formate to the mixed solution B1, and stir evenly to obtain a ring space protection solution.

Embodiment 2

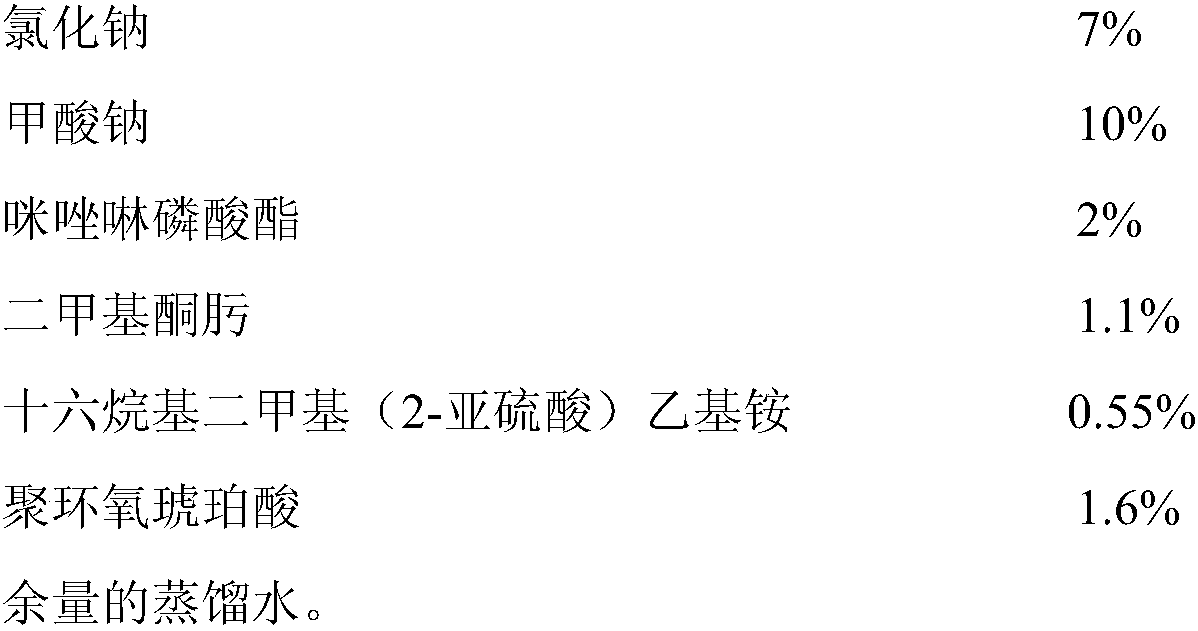

[0035] This embodiment provides an annulus protection solution. In terms of weight percentage, the raw materials for preparing the annulus protection solution include:

[0036]

[0037] This embodiment also provides a preparation method for the above-mentioned annulus protection solution, which includes the following steps:

[0038] Step 1, according to the above ratio, add distilled water and cetyldimethyl (2-sulfite) ethyl ammonium into the reaction kettle, stir evenly to obtain the mixed solution A2;

[0039] Step 2, adding polyepoxysuccinic acid and dimethyl ketoxime to the mixed solution A2, stirring evenly to obtain the mixed solution B2;

[0040] Step 3: Add imidazoline phosphate, sodium chloride and sodium formate to the mixed solution B2, and stir evenly to obtain a ring space protection solution.

Embodiment 3

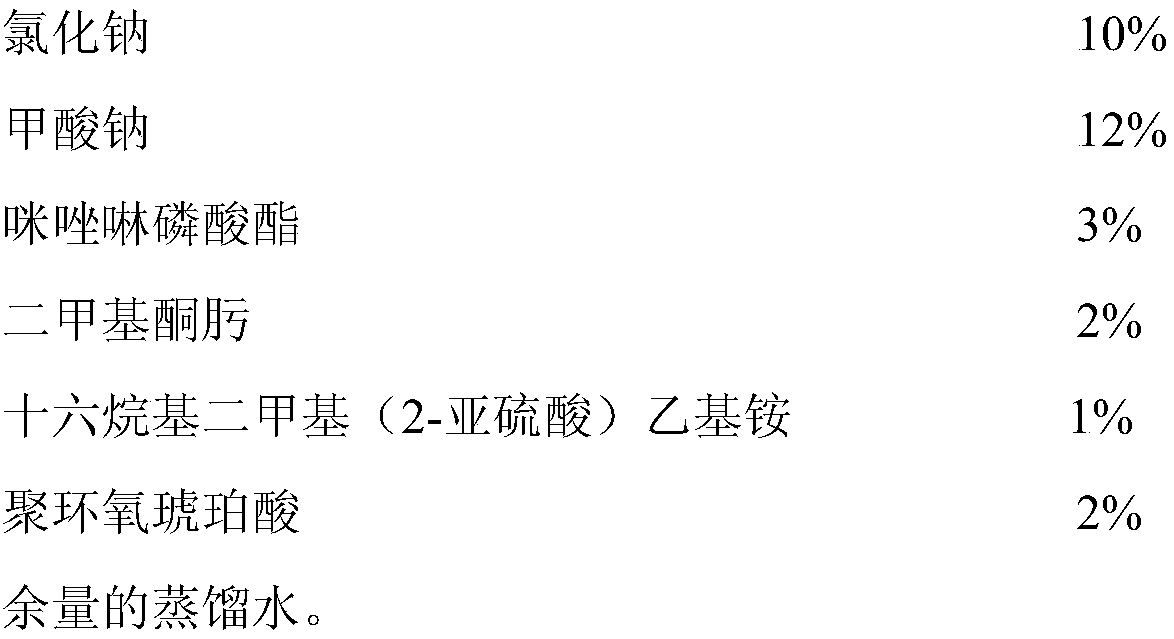

[0042] This embodiment provides an annulus protection solution. In terms of weight percentage, the raw materials for preparing the annulus protection solution include:

[0043]

[0044] This embodiment also provides a preparation method for the above-mentioned annulus protection solution, which includes the following steps:

[0045] Step 1, according to the above ratio, add the mixture of distilled water, N-octyl-diaminoethylglycine and N,N-dioctyl-diaminoethylglycine (the mass ratio before and after the two is 1:3) to In the reaction kettle, stir evenly to obtain the mixed solution A3;

[0046] Step 2, adding polyaspartic acid and acetaldehyde oxime to the mixed solution A3, stirring evenly to obtain the mixed solution B3;

[0047] Step 3: Add imidazoline phosphorothioate, potassium chloride and potassium formate to the mixed solution B3, and stir evenly to obtain a ring space protection solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com