Hardware-in-loop simulation testing system and method based on power level virtual motor

A simulation test, power level technology, applied in the direction of test/monitoring control system, electrical test/monitoring, general control system, etc., can solve the problem that the motor ripple current cannot be truly restored, and the control characteristics and performance of the motor controller cannot be truly reflected, etc. problem, to achieve the effect of improving current tracking bandwidth, reducing secondary interference, and high safety redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

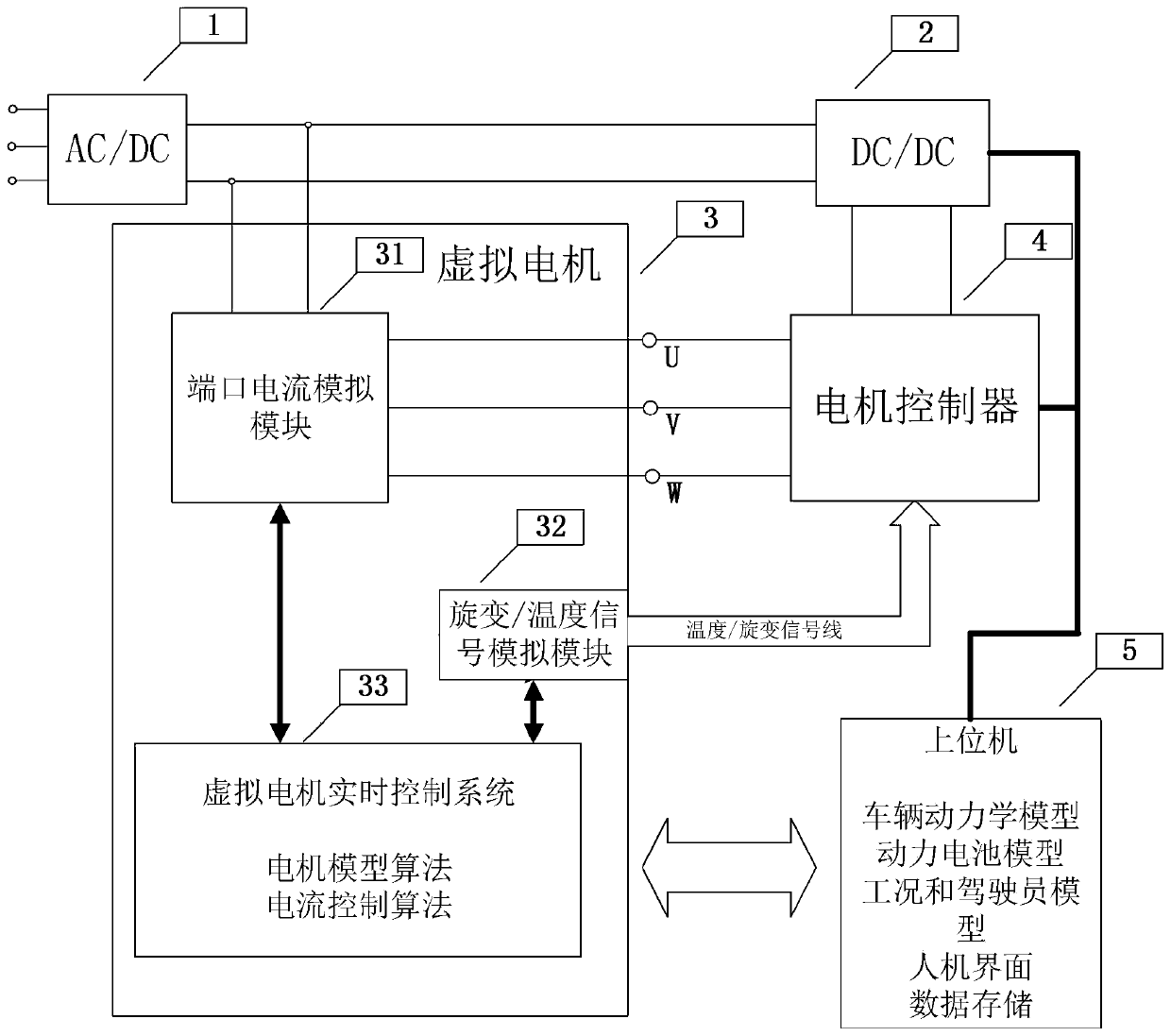

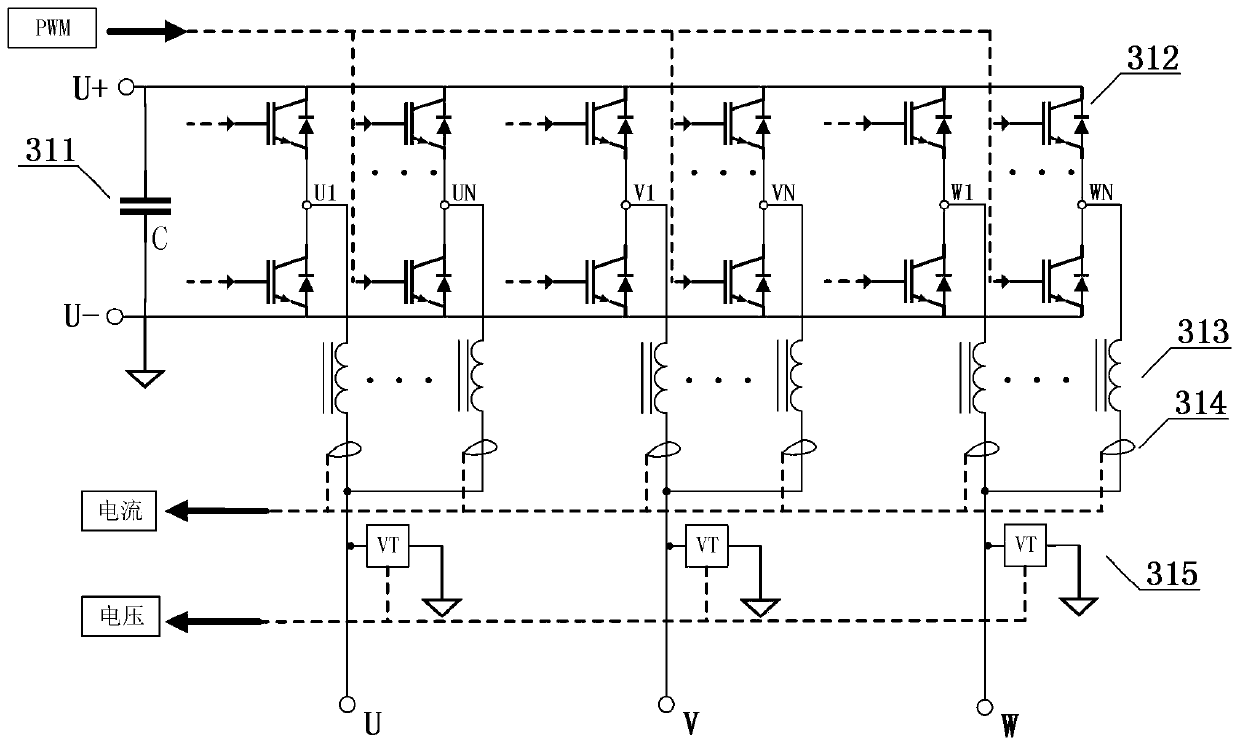

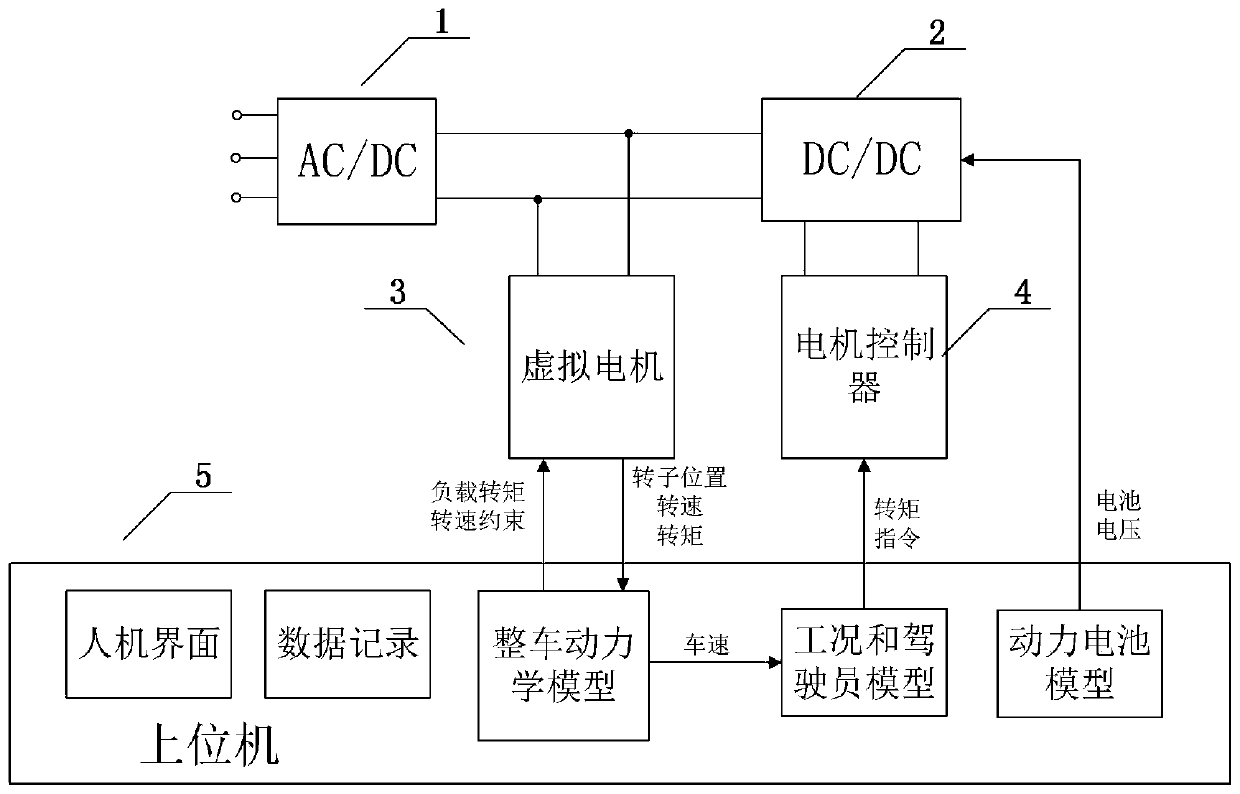

[0043] as attached figure 1 As shown, a hardware-in-the-loop simulation test system based on a power stage virtual motor includes an isolated AC / DC rectifier module 1, an isolated DC / DC module 2, a power stage virtual motor 3, a motor controller under test 4 and an upper Machine 5, characterized in that the power stage virtual motor includes a port current simulation module 31, a resolver / temperature signal simulation module 32, and a virtual motor real-time control system 33. After the AC power is connected to the system, it is rectified by the isolated AC / DC rectifier module 1 and then converted into a stable first-level DC power supply, which supplies power for the isolated DC / DC module 2 and the power stage virtual motor 3. After being rectified by the isolated DC / DC module 2 The converted secondary DC power supply supplies power to the motor controller 4 under test, and the host computer 5 provides torque commands for the motor controller 4 under test according to the veh...

Embodiment 2

[0049] This embodiment provides a hardware-in-the-loop simulation test method based on a power-level virtual motor, including the following steps:

[0050] A. After the AC power is connected to the system, it is rectified by the isolated AC / DC rectifier module 1 and then converted into a stable DC power supply, which supplies power for the isolated DC / DC module 2 and the power stage virtual motor 3. After being rectified by the isolated DC / DC module 2 The converted secondary DC power supplies power to the motor controller 4 under test;

[0051] B. The upper computer 5 runs the power battery model, vehicle dynamics model, working conditions and driver model, and provides man-machine interface and data recording functions. The power battery model provides voltage commands for the isolated DC / DC module 2 to simulate driving The battery voltage changes during the process, the vehicle dynamics model provides load torque or speed constraint parameters for the power stage virtual mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com