Solar power generation pavement component

A solar panel and solar technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the power generation efficiency of photovoltaic pavement, prone to cracks and fractures on the surface, and prone to cracks in the wear-resistant layer, so as to improve vehicle performance. , Improve the light transmittance, not easy to break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

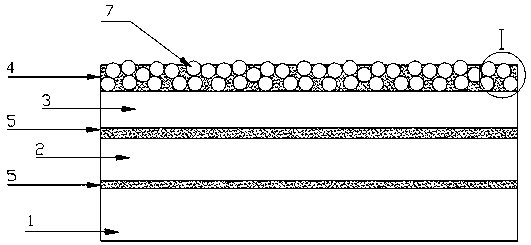

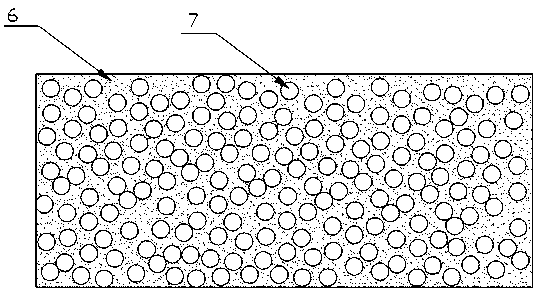

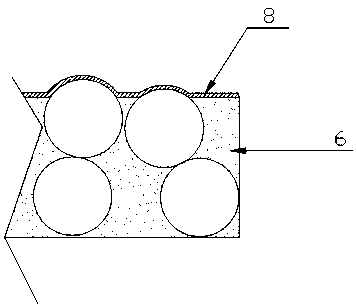

[0026] Mix the light-transmitting polymer and the light-transmitting aggregate particles according to the following volume ratio: 40 parts of light-transmitting polymer and 60 parts of light-transmitting aggregate particles, wherein the light-transmitting polymer is HDPE, and the light-transmitting aggregate particles are round Spherical quartz particles are mixed and placed above the protective layer of the pavement module, and the pavement module of the solar power generation pavement assembly of the present invention is prepared by hot melting or hot pressing process and temperature control process, and then sprayed on the surface of the light-transmitting abrasion layer 1mm Thick protective top layer.

[0027]The design parameters of the wear layer of the pavement module and the test results of the light transmittance and anti-skid safety performance of the pavement module are shown in Table 1. Among them, each test group of the anti-skid test (JTJ 059T0964) and light trans...

Embodiment 2

[0031] Mix the light-transmitting polymer and the light-transmitting aggregate particles according to the following proportions by volume: 35 parts of light-transmitting polymer and 65 parts of light-transmitting aggregate particles. Spherical glass particles are mixed and placed above the protective layer of the pavement module, and the pavement module of the solar power generation pavement assembly of the present invention is prepared by hot-melt or hot-pressing process and temperature control process, and then sprayed on the surface of the light-transmitting abrasion layer 1mm Thick protective top layer.

[0032] The design parameters of the wear layer of the pavement module and the test results of the light transmittance and anti-skid safety performance of the pavement module are shown in Table 1. Among them, each test group of the anti-skid test (JTJ 059T0964) and light transmittance test (GB / T 30983) The samples were tested at least 6 times in parallel, and the average v...

Embodiment 3

[0036] Mix the light-transmitting polymer and the light-transmitting aggregate particles according to the following volume ratio: 50 parts of light-transmitting polymer and 50 parts of light-transmitting aggregate particles, wherein the light-transmitting polymer is LDPE, and the light-transmitting aggregate particles are round The combination of spherical plastic particles and metal particles is mixed and placed above the protective layer of the pavement module, and the pavement module of the solar power generation pavement assembly of the present invention is prepared by hot-melting or hot-pressing process and temperature control process, and then it is worn after light transmission The surface of the layer is sprayed with a 1mm thick protective surface layer.

[0037] The design parameters of the wear layer of the pavement module and the test results of the light transmittance and anti-skid safety performance of the pavement module are shown in Table 1. Among them, each test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com