Preparation method of Cu/SiO2 catalyst modified by Na salt and application of preparation method

A technology of catalysts and compounds, applied in the field of Cu/SiO2 catalysts, can solve the problems of few modifiers and unclear essential reasons for the selectivity of propylene oxide, and achieve energy-saving and high-efficiency processes, low catalyst costs, and increased production rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

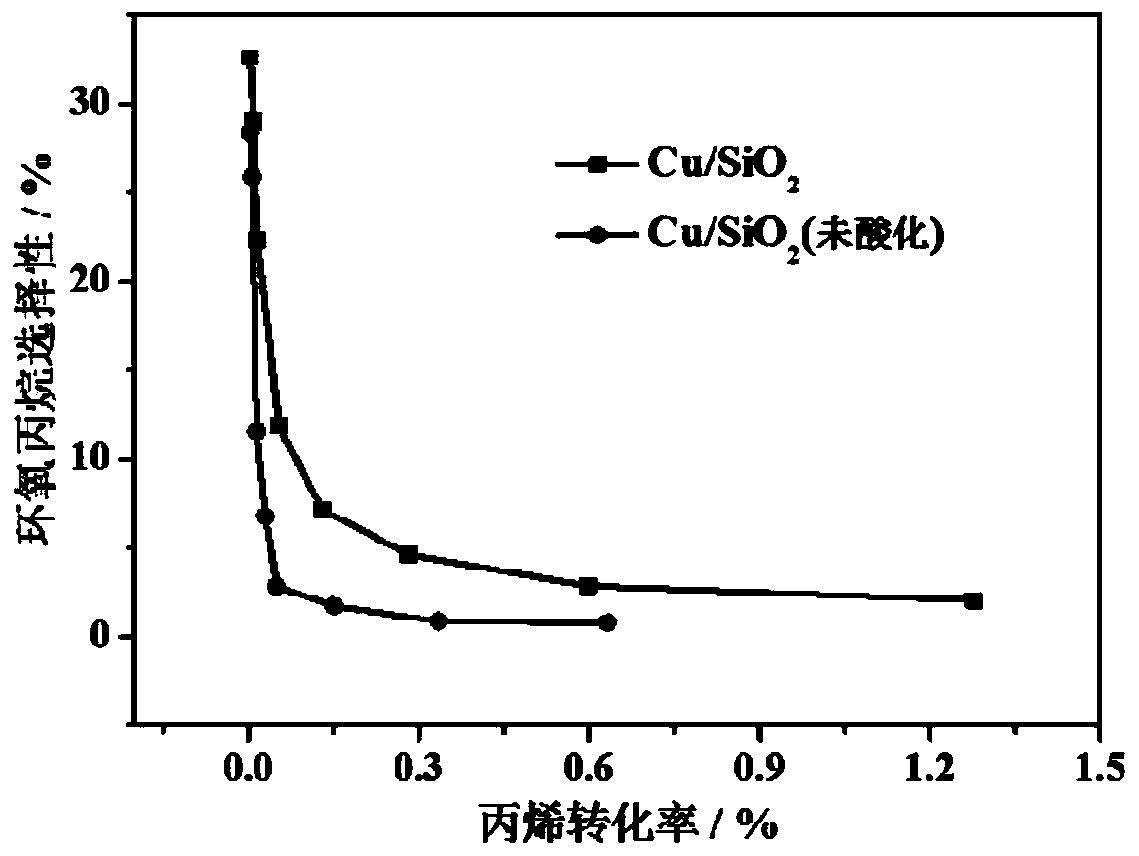

[0040] 2) Cu / SiO 2 sample preparation

[0041] Preparation of Cu / SiO by Homogeneous Precipitation Method 2 Samples (where Cu oxides (CuO and Cu 2 O) the mass fraction is 5%):

[0042] Weigh 0.95g of Cu precursor compound Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100ml double distilled water, then added 4.75g of the acidified SiO obtained in step 1). 2 Solid (i.e. carrier), then slowly add dropwise the aqueous solution 10ml that contains 2.34g precipitation agent urea, Cu(NO 3 ) 2 ·3H 2 The molar ratio of O to urea is 1:10. Stir the mixed sample for 0.5h; then put the mixed system into an oil bath at 100°C, heat it with stirring and keep it for about 24h; wash the obtained solid sample with twice distilled water until neutral, and dry it in a vacuum oven at 100°C for 10h , to obtain light green solid Cu / SiO 2 sample;

[0043] 3) Na salt modified Cu / SiO 2 catalyst

[0044] Na salt accelerator modified Cu / SiO 2 The catalyst is prepared by wet impregnation method:

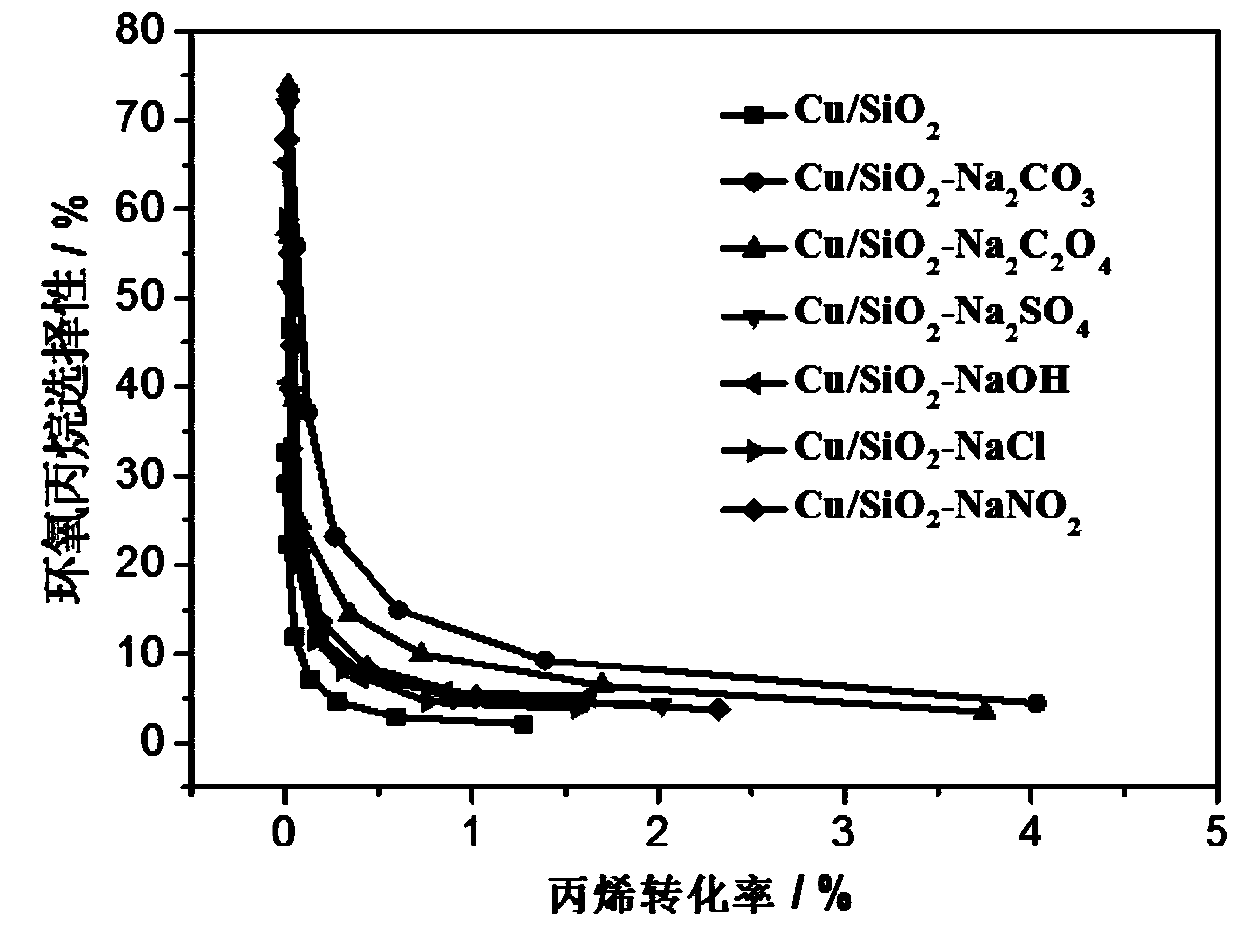

Embodiment 1-7

[0047] Prepare Cu / SiO modified with different Na salts following the above procedure 2 catalyst. Embodiment 1 does not add Na salt accelerator in step 3); Embodiment 2-7 uses NaNO respectively in step 3) successively 2 、Na 2 SO 4 , NaCl, Na 2 C 2 o 4 、Na 2 CO 3 , NaOH as Na salt promoter. In embodiment 1-7, when carrying out step 3), its Cu / SiO 2 The amount of sample, the amount of Na salt accelerator and the amount of water are shown in Table 1 below, and the obtained Na salt modified Cu / SiO 2 In the catalyst, the molar ratios of Na and Cu are shown in Table 1, respectively.

[0048] Table 1: Partial synthesis conditions of step 3)

[0049]

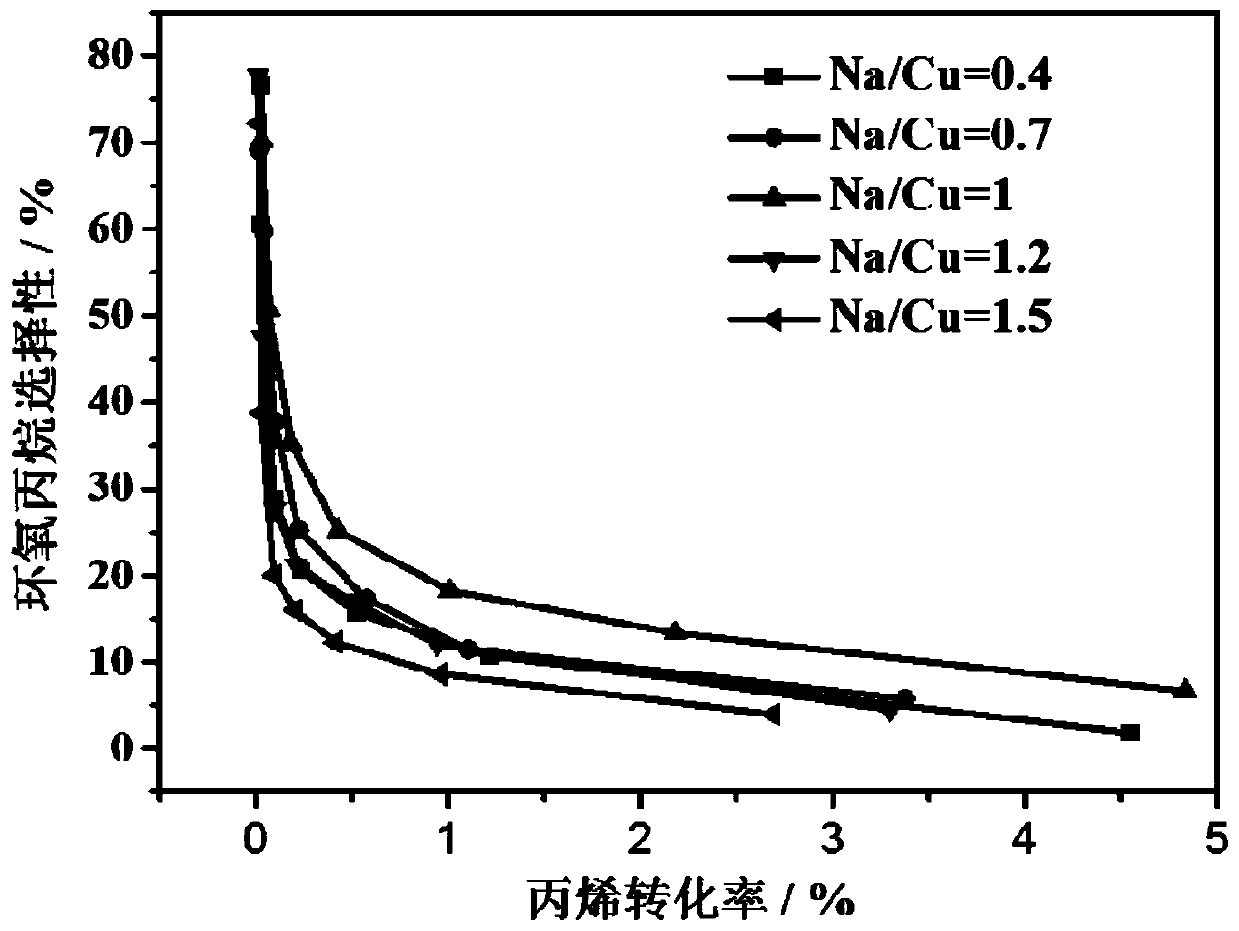

Embodiment 8-12

[0055] Follow the steps above to prepare different Na 2 CO 3 Modified Cu / SiO 2 catalyst. In embodiment 8-12, when carrying out step 3), its Cu / SiO 2 Sample dosage, Na salt promoter (Na 2 CO 3 ) consumption and the consumption of water are all referred to as shown in table 2 below, gained Na 2 CO 3 Modified Cu / SiO 2 In the catalyst, the molar ratios of Na and Cu are shown in Table 2, respectively.

[0056] Table 2: Partial synthesis conditions of step 3)

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com