Removal method and removal evaluation method of micro-fluidic chip support materials based on 3D printing

A technology of microfluidic chips and supporting materials, applied in 3D object support structures, additive processing, metal processing equipment, etc., can solve the problems of chip structure damage, chip surface blurring and whitening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

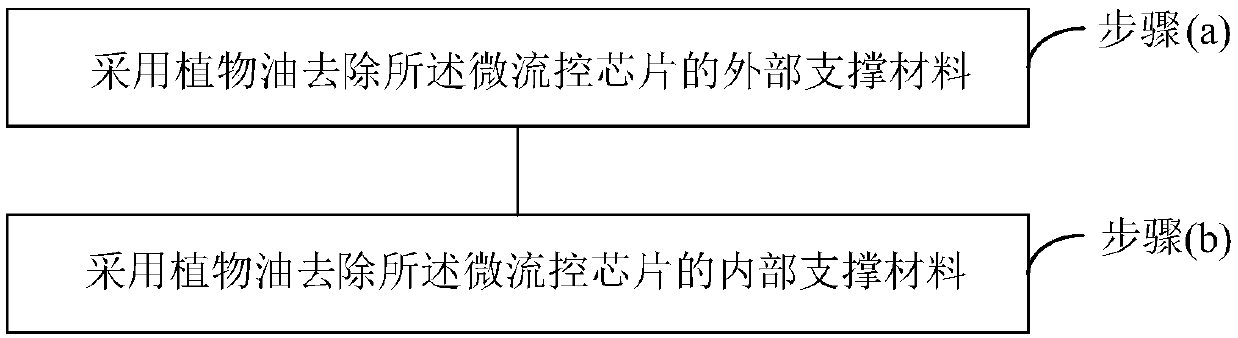

[0054] See figure 2 , figure 2 It is a schematic flowchart of a method for removing support material of a microfluidic chip based on 3D printing provided by an embodiment of the present invention. The removal of the supporting material of the microfluidic chip can be achieved in the following manner.

[0055] A method for removing a support material of a microfluidic chip based on 3D printing, comprising the steps of:

[0056] (a) using vegetable oil to remove the external support material of the microfluidic chip;

[0057] (b) Using vegetable oil to remove the internal support material of the microfluidic chip.

[0058] In a specific embodiment, the removal of the external support material of the microfluidic chip is completed by heating the microfluidic chip, and then the vegetable oil is injected into the microfluidic chip to complete the microfluidic chip. Removal of support material inside the chip.

[0059] In a specific embodiment, the removal of the external sup...

Embodiment 2

[0062] Please refer to FIG. 1 again. On the basis of the above-mentioned embodiments, this embodiment focuses on a detailed description of the specific process of a method for removing the supporting material of a microfluidic chip based on 3D printing.

[0063] (S10) Using vegetable oil to remove the external support material of the microfluidic chip.

[0064] In a specific embodiment, the vegetable oil is vegetable oil such as peanut oil and rapeseed oil.

[0065] The principle of the embodiments of the present invention is to find a solvent that is similar in polarity and structure to the chemical composition of the support material according to the law of like dissolves like. The main chemical components of the supporting material wax are fatty acids, fatty alcohols and oils. In the embodiment of the present invention, vegetable oil is selected as the solvent, which has the property of being miscible with the wax as vegetable oil, and the vegetable oil has relatively large...

Embodiment 3

[0094] This example describes in detail a method for removing the support material of a microfluidic chip with a specific internal channel shape.

[0095] Using CDA software to design and draw a microfluidic chip with one inlet and three outlets, the 3D printed chip is produced with Projet 3500HD equipment. The cross-sectional shape of the internal channel of the microfluidic chip is rectangular, with width and height respectively 400 microns and 200 microns, the molding material is yellow translucent photosensitive resin, and the support material is 100% wax-type material. Pour the vegetable oil into the tin box and heat it at a constant temperature to 70°C, place the microfluidic chip in the vegetable oil and heat it in a water bath, after heating to 70°C, keep it warm for 20 minutes, and remove the external support material of the microfluidic chip; then , use a rubber hose to connect the entrance of the internal channel of the microfluidic chip with the constant flow pump,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com