A kind of antirust environment-friendly cement-based material and its preparation method and application

A cement-based material and an environmentally friendly technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as threats to the safety of pedestrians and vehicles under the bridge, poor durability of paint, and rusting of overpass column feet, etc., to achieve high Adhesive performance, good water resistance, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

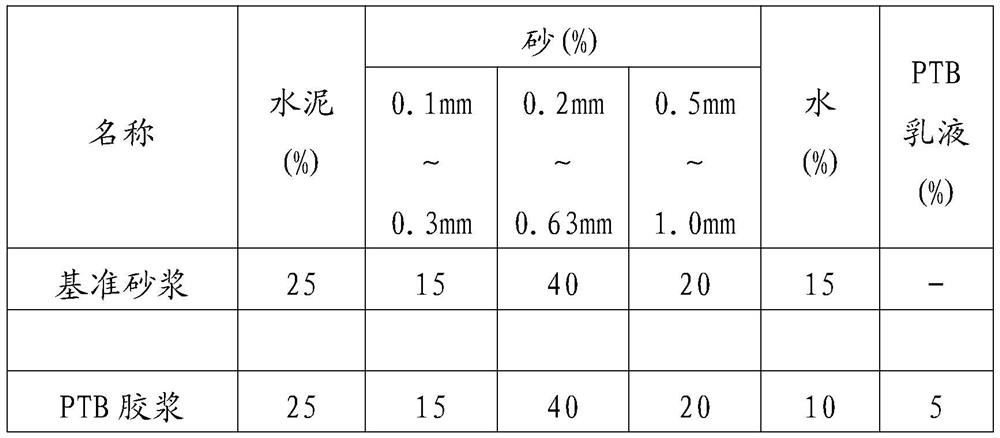

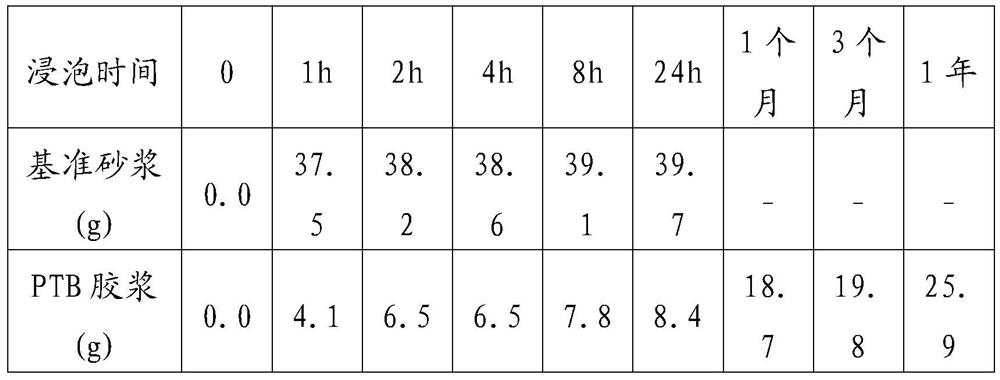

Method used

Image

Examples

Embodiment 1

[0037] It is mainly composed of sodium carbonate, calcium hydroxide, sand, slag, PTB emulsion and water, and the mass percentage of each component is: Na 2 CO 3 2.2%, Ca(OH) 2 1.5%, sand 58.0%, slag 25.3%, PTB emulsion 4.3%, water 8.7%, the mass percentage sum of each component is 100%.

[0038] The specific steps of the preparation method of the anti-rust environmental protection cement-based material of the present invention are:

[0039] (1) Metering: measure each component material according to the above ratio;

[0040] (2) Mix dry ingredients: pour sodium carbonate, calcium hydroxide and slag into a mixer and dry mix for 2 to 3 minutes, then pour sand and stir for 2 to 3 minutes to obtain evenly mixed dry ingredients;

[0041] (3) Preparation of antirust material: Dissolve PTB emulsion in water and stir for 2 to 3 minutes to form a PTB solution; then pour the PTB solution into the mixed dry material and stir for 2 to 3 minutes to make an antirust and environmentally fr...

Embodiment 2

[0045]It is mainly composed of sodium carbonate, calcium hydroxide, sand, slag, PTB emulsion and water, and the mass percentage of each component is: Na 2 CO 3 1.2%, Ca(OH) 2 0.8%, sand 68.2%, slag 20.2%, PTB emulsion 3.1%, water 6.5%, the mass percentage sum of each component is 100%.

[0046] The specific steps of the preparation method of the anti-rust environmental protection cement-based material of the present invention are:

[0047] (1) Metering: measure each component material according to the above ratio;

[0048] (2) Mix dry ingredients: pour sodium carbonate, calcium hydroxide and slag into a mixer and dry mix for 2 to 3 minutes, then pour sand and stir for 2 to 3 minutes to obtain evenly mixed dry ingredients;

[0049] (3) Preparation of antirust material: Dissolve PTB emulsion in water and stir for 2 to 3 minutes to form a PTB solution; then pour the PTB solution into the mixed dry material and stir for 2 to 3 minutes to make an antirust and environmentally fri...

Embodiment 3

[0053] It is mainly composed of sodium carbonate, calcium hydroxide, sand, slag, PTB emulsion and water, and the mass percentage of each component is: Na 2 CO 3 3.2%, Ca(OH) 2 2.2%, sand 31.6%, slag 46.6%, PTB emulsion 5.7%, water 10.7%, the mass percentage sum of each component is 100%.

[0054] The specific steps of the preparation method of the anti-rust environmental protection cement-based material of the present invention are:

[0055] (1) Metering: measure each component material according to the above ratio;

[0056] (2) Mix dry ingredients: pour sodium carbonate, calcium hydroxide and slag into a mixer and dry mix for 2 to 3 minutes, then pour sand and stir for 2 to 3 minutes to obtain evenly mixed dry ingredients;

[0057] (3) Preparation of antirust material: Dissolve PTB emulsion in water and stir for 2 to 3 minutes to form a PTB solution; then pour the PTB solution into the mixed dry material and stir for 2 to 3 minutes to make an antirust and environmentally f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com