Self-stabilizing steam pressurization system and working method thereof

A pressurized system, self-stabilizing technology, applied in pipeline systems, components of pumping devices for elastic fluids, gas/liquid distribution and storage, etc., can solve noise pollution, low degree of automation, and poor sealing effect of high-pressure steam to avoid misjudgment and liberate the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

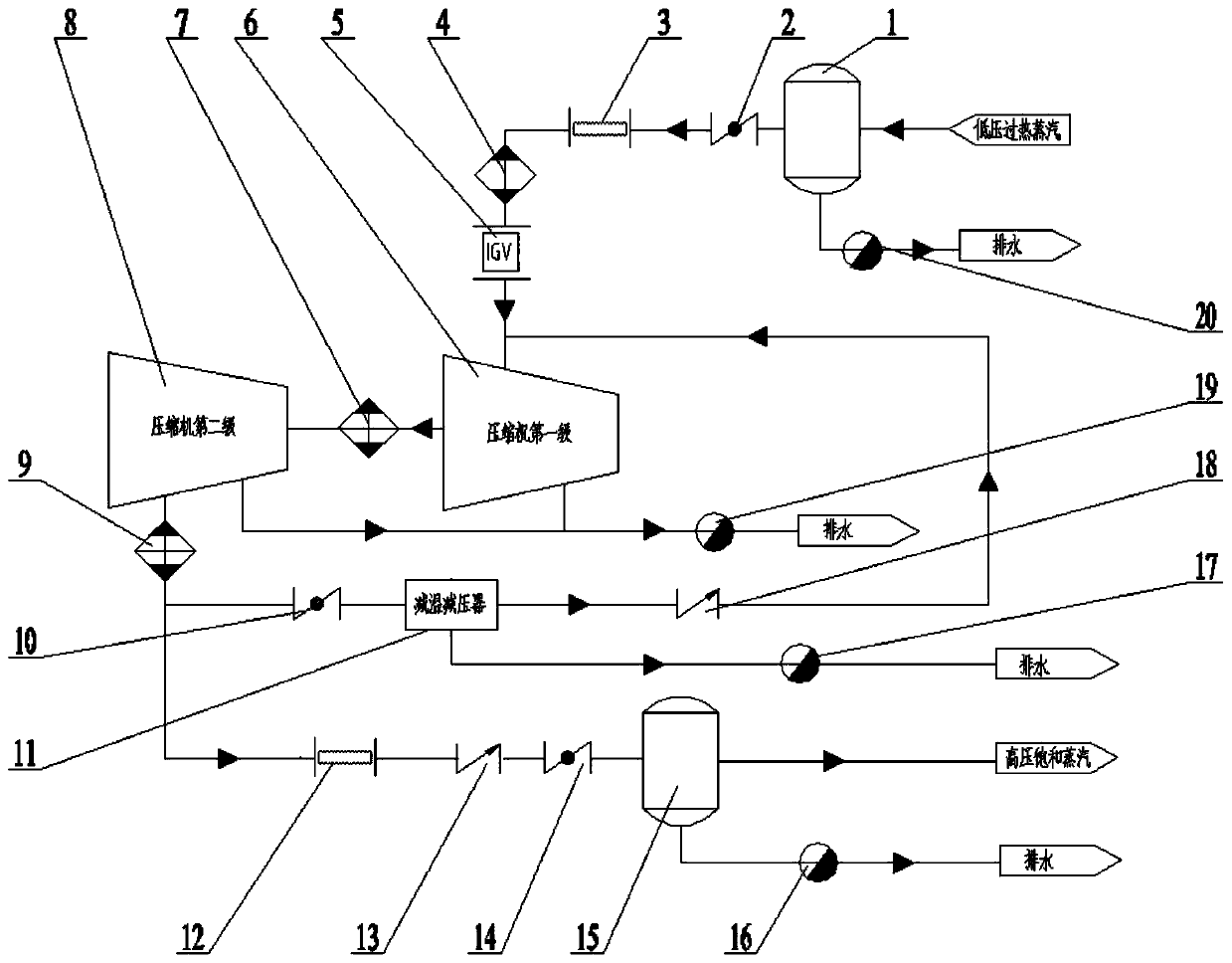

[0033] A self-stabilizing steam pressurization system, the structural principle diagram is as follows figure 1 As shown, the system mainly includes the inlet buffer tank 1, the inlet butterfly valve 2, the inlet bellows 3, the inlet sprinkler 4, the inlet guide vane mechanism 5, the first stage of the compressor 6, and the interstage sprinkler 7 , the second stage of the compressor 8, the exhaust steam sprinkler 9, the anti-breathing regulating valve 10, the temperature and pressure reducer 11, the exhaust bellows 12, the check valve 13, the exhaust butterfly valve 14, the exhaust buffer tank 15, Steam trap 16, steam trap 17, check valve 18, steam trap 19, steam trap 20, etc. Among them, the inlet buffer tank 1 and the exhaust buffer tank 15 are equipped with safety valves, which play the role of safety pressure relief; the inlet butterfly valve 2 and the exhaust butterfly valve 14 are switch-type butterfly valves, which play the role of opening and closing the pipeline. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com