Motor control device and electric power steering device provided with same

A motor control and motor technology, which is applied to electric steering mechanisms, power steering mechanisms, steering rods, etc., can solve problems such as torque generation efficiency drop, loss of step, estimated angle error, etc., to reduce angle error, simple structure, and suppress angle. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0055] (structure)

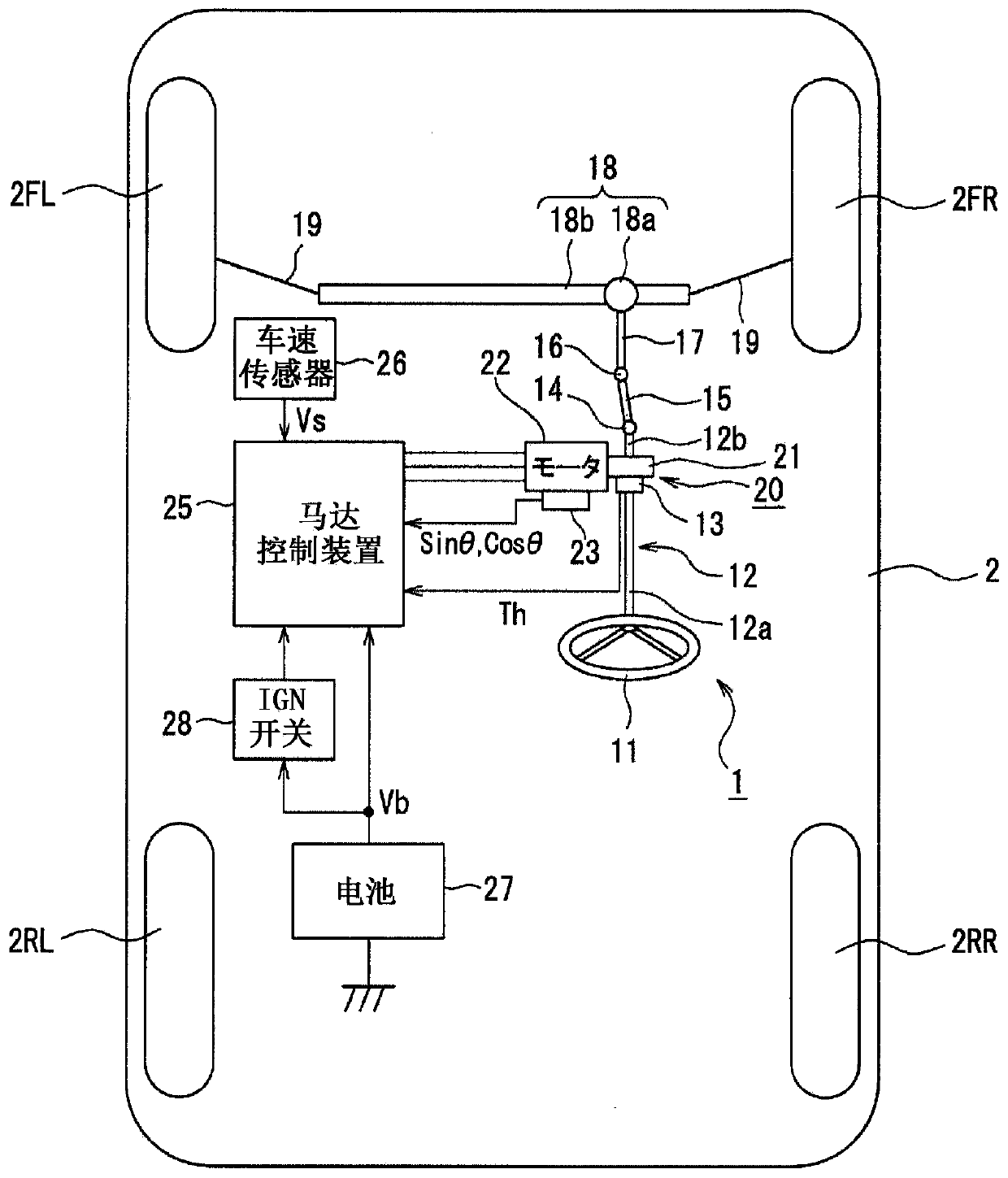

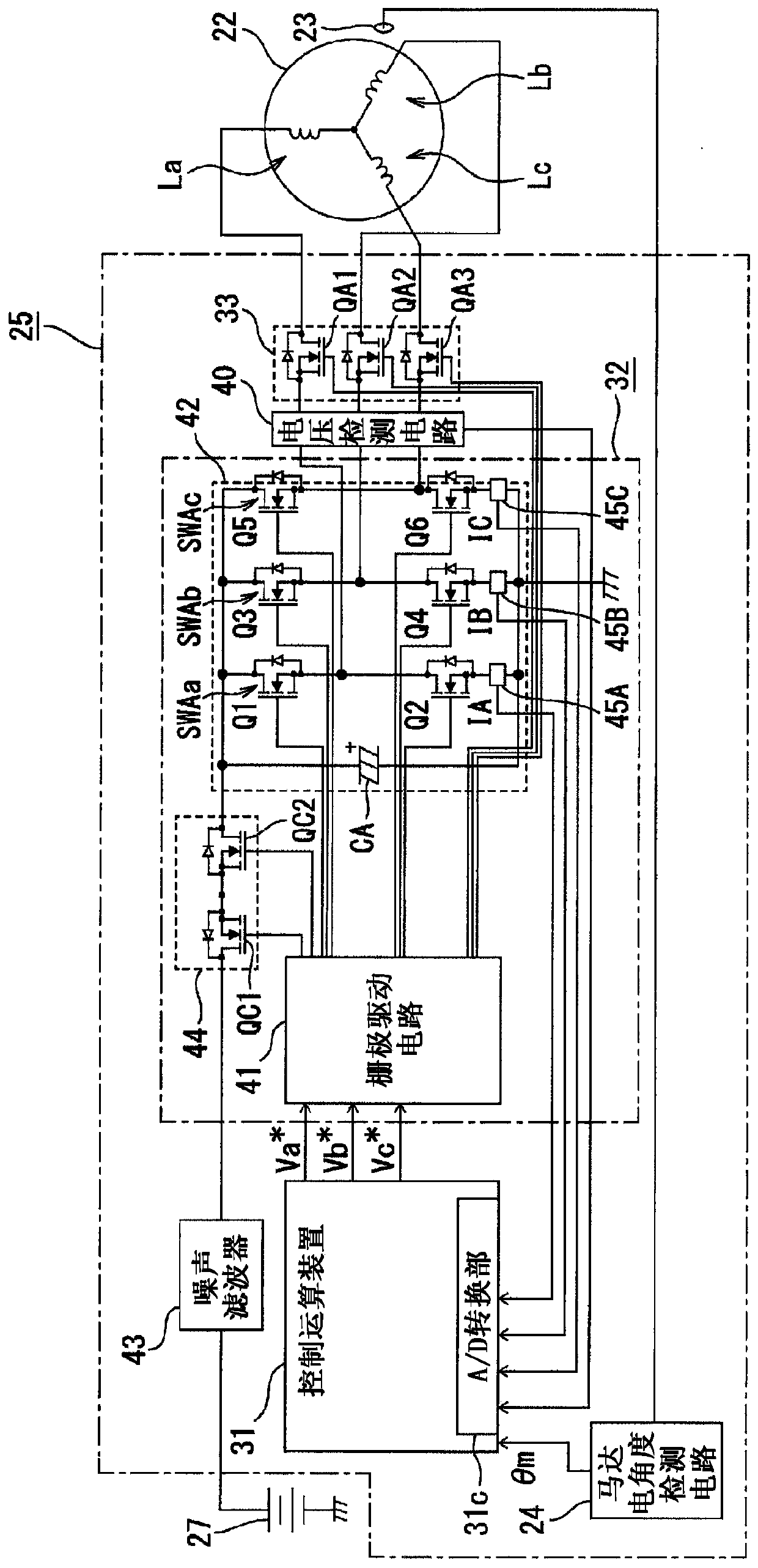

[0056] Such as figure 1 As shown, vehicle 2 according to the embodiment of the present invention has front wheels 2FR and 2FL and rear wheels 2RR and 2RL as left and right steering wheels. Front wheels 2FR and 2FL are steered by electric power steering device 1 .

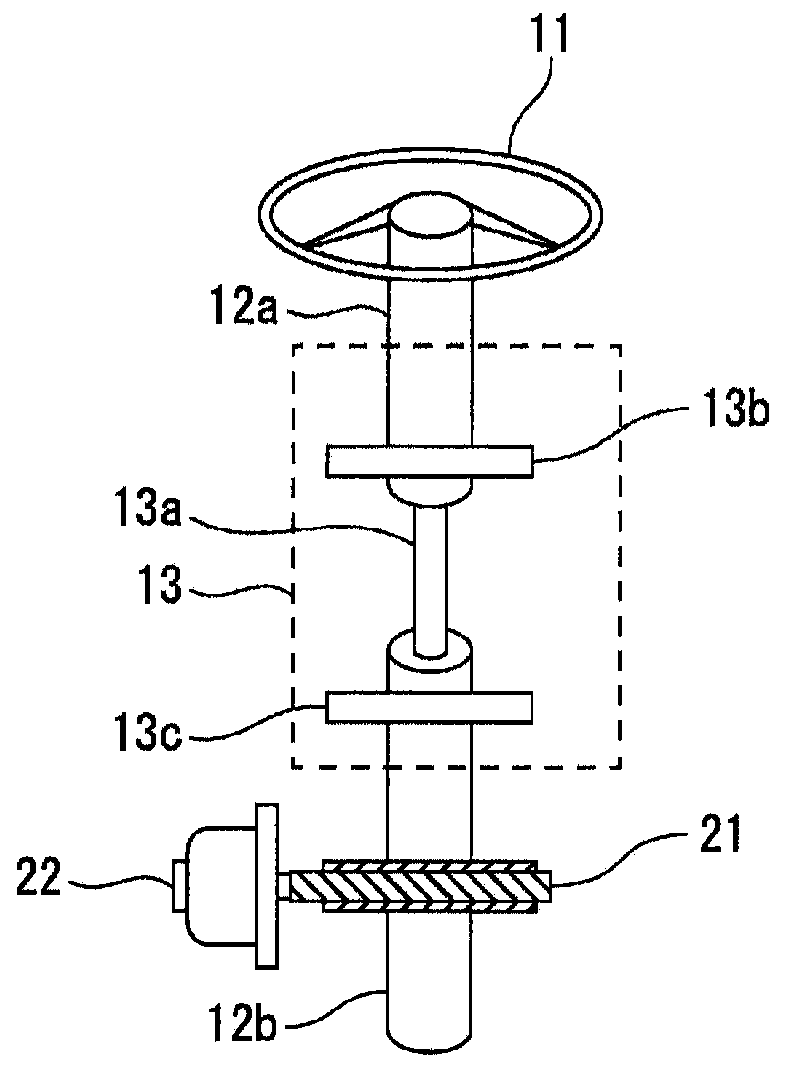

[0057] The electric power steering apparatus 1 has a steering wheel 11 , and a steering force applied to the steering wheel 11 by a driver is transmitted to a steering shaft 12 . The steering shaft 12 has an input shaft 12a and an output shaft 12b. One end of the input shaft 12 a is coupled to the steering wheel 11 , and the other end is coupled to one end of the output shaft 12 b via a steering torque sensor 13 .

[0058] Furthermore, the steering force transmitted to the output shaft 12 b is transmitted to the lower shaft 15 via the universal joint 14 , and is further transmitted to the pinion shaft 17 via the universal joint 16 . The steering force transmitted to the pinion shaft 17 is tr...

no. 2 Embodiment approach

[0326] Next, a second embodiment of the present invention will be described.

[0327] (structure)

[0328] In the first embodiment described above, the lead correction limit value SgL is calculated considering only the reduction gear error characteristic of the reduction gear 21. However, in the second embodiment, the output shaft rotation angle sensor 13c is also considered in addition to the reduction gear error characteristic. The detection error characteristic is different from the first embodiment described above. Other than that, it is the same structure as the said 1st Embodiment.

[0329] Hereinafter, the same reference numerals will be attached to the same structural parts as those of the first embodiment, and descriptions will be omitted as appropriate, and different parts will be described in detail.

[0330] (Inter-sensor error correction unit 54)

[0331] Such as Figure 23 As shown, the inter-sensor error correction unit 54 of the second embodiment has a conf...

no. 3 Embodiment approach

[0372] Next, a third embodiment of the present invention will be described.

[0373] (structure)

[0374] In the above-mentioned first embodiment, the leading gain is set to a value equal to or greater than "1" and the leading gain is multiplied by the output shaft angular velocity ωos to calculate the leading front and rear steering angular velocity ωosc. However, in the third embodiment, the leading gain is set to The value "0" or more is different from the first embodiment in that the lead correction update amount Cr is calculated by multiplying the lead gain by the output shaft angular velocity ωos. Also, it is different in that the leading-rear steering angular velocity ωosc is calculated by multiplying the output shaft angular velocity ωos by the leading correction update amount Cr. The structures other than these are the same as those of the above-mentioned first embodiment.

[0375] Hereinafter, the same reference numerals will be attached to the same structural part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com