Diamond nozzle of ultra-high pressure liquid jet and manufacturing method of diamond nozzle

A liquid jet and ultra-high pressure technology, applied in the direction of injection devices, injection devices, etc., can solve the problems of jet quality degradation, failure, and edge fragmentation of gem orifices, etc., to achieve good jet effect, increased service life, and high flow coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

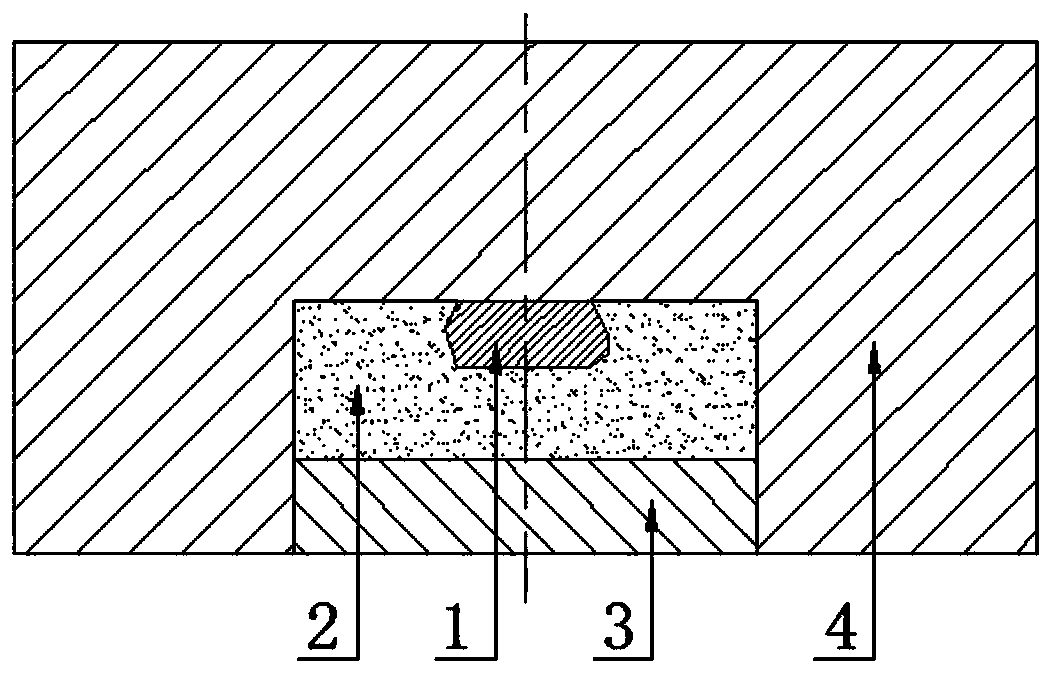

[0045] See figure 1 , image 3 , Figure 4 with Figure 5 , An ultra-high-pressure liquid jet diamond nozzle, comprising a diamond sheet 1, a metal nanopowder layer 2, a metal gland 3, and a metal casing 4, the metal casing 4 is provided with a built-in cavity, and the metal gland 3 is covered Fixed at the bottom of the built-in cavity, the built-in cavity is filled with metal nanopowder and forms a metal nanopowder layer 2. The metal nanopowder layer 2 is provided with a diamond sheet 1, which is set on a metal The central axis of the shell 4 is located in contact with the inner wall of the inner cavity of the metal shell 4, the metal nano powder layer 2 tightly wraps the diamond sheet 1 and the metal shell 4 is integrated.

[0046] The top of the metal shell 4 is provided with an upper opening 5, the metal gland 3 is provided with a lower opening 6, the diamond sheet 1 is provided with a nozzle through hole 7, and the bottom of the upper opening 5 The cone, the top cone of the ...

Embodiment 2

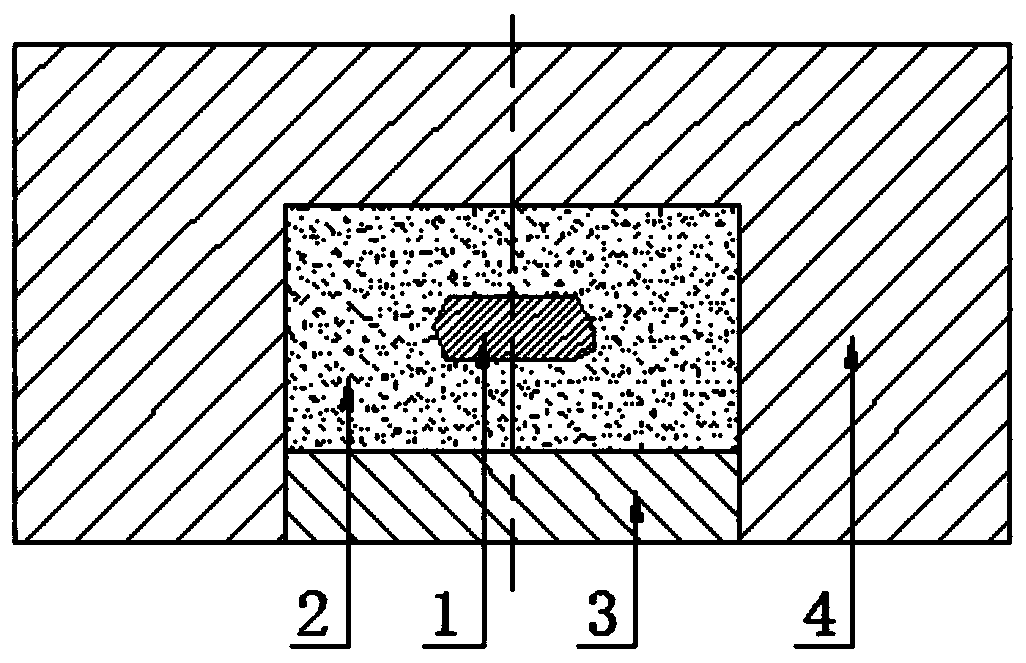

[0053] See figure 2 , image 3 , Image 6 with Figure 7 This embodiment is used as a further implementation structure of the first embodiment. On the basis of this, the diamond sheet 1 is arranged at the central axis position of the metal shell 4 and completely wrapped in the inner cavity of the metal nano powder layer 2. The bottom cone tip of the upper opening 5 extends to the inner cavity of the metal nano powder layer 2, and a tapered opening is formed on the top of the metal nano powder layer 2. The diamond sheet 1 is not in contact with the metal shell 4 and is completely wrapped in the inner cavity of the metal nano powder layer 2.

[0054] Preferably, see Figure 8-13 , The illustrations are all diamonds with different hole types and structures after being processed to meet the needs of different types of processing operations.

[0055] Regarding the diamond nozzle described in this application, a method of ultra-high pressure liquid jet diamond nozzle is also disclosed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com