System and device for treating circulating cooling water by using lime softening and ozone

A technology of circulating cooling water and lime softening, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water softening, etc., can solve problems affecting heat exchange efficiency and blockage of heat exchange equipment, and achieve reduction of chemical precipitates, High degree of intelligence, the effect of reducing time and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

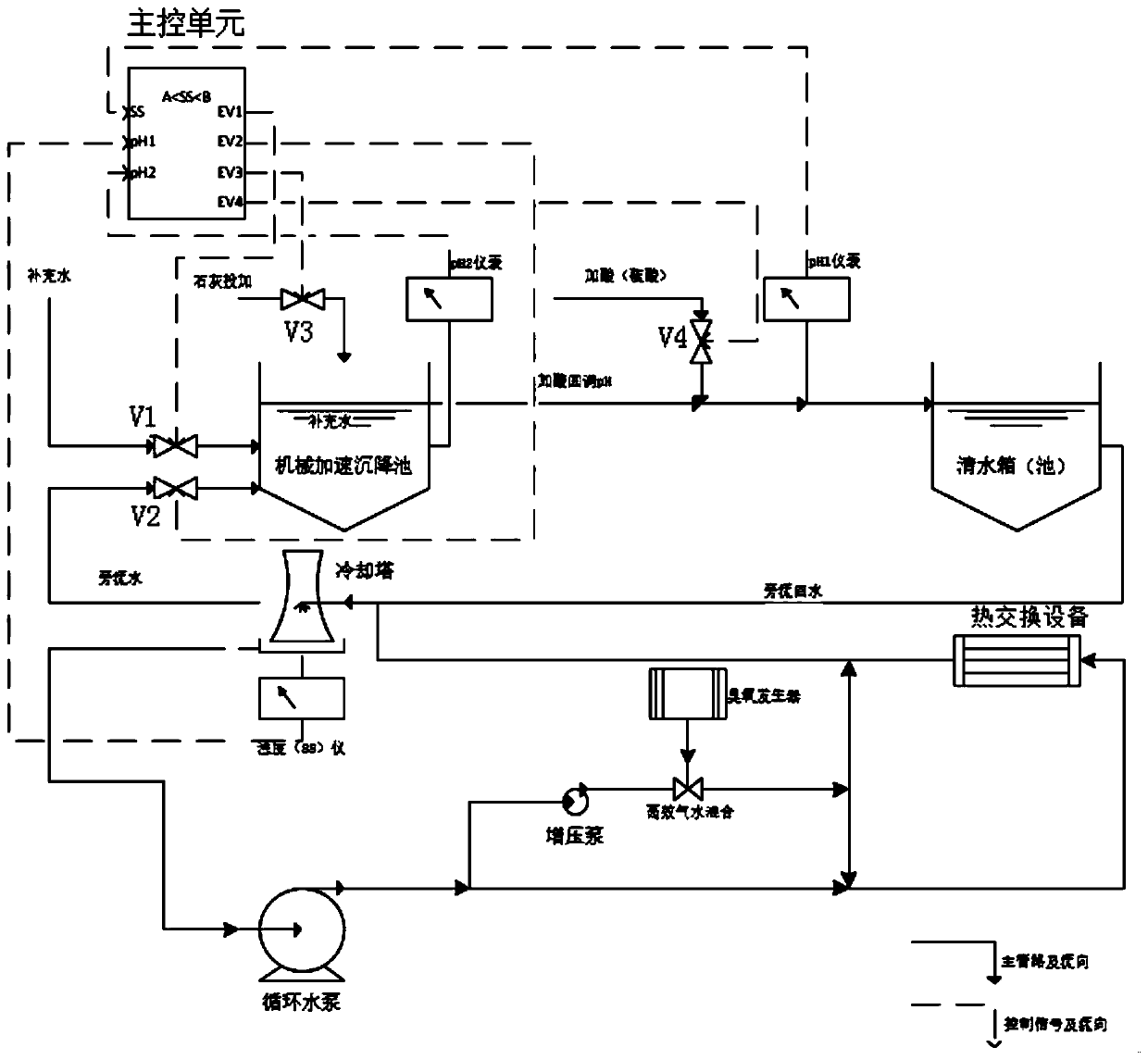

[0020] see figure 1 , a system for lime softening and ozone treatment of circulating cooling water, comprising a lime softening treatment system, a circulating cooling water system treated with ozone technology, and a control system; the lime softening treatment system is sequentially provided with a mechanically accelerated sedimentation tank and a sump , cooling tower, the second automatic valve V2 is provided between the cooling tower and the mechanical accelerated sedimentation tank; the mechanical accelerated sedimentation tank is also communicated with the supplementary water source through the first automatic valve V1; the lime addition path of the mechanical accelerated sedimentation tank is provided with The third automatic valve V3; the fourth automatic control valve V4 is provided on the acid adding channel of the lime softening circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com