High-carbon-black tracking-resistant silane crosslinked polyethylene insulating material and preparation method thereof

A polyethylene insulation, silane cross-linking technology, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of signal transmission distortion, corrosion of cable structure, cable material or structure can not meet the needs of the industry, etc. , to achieve the effect of reducing the possibility, the extrusion surface is smooth and delicate, and the extrusion process range is wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

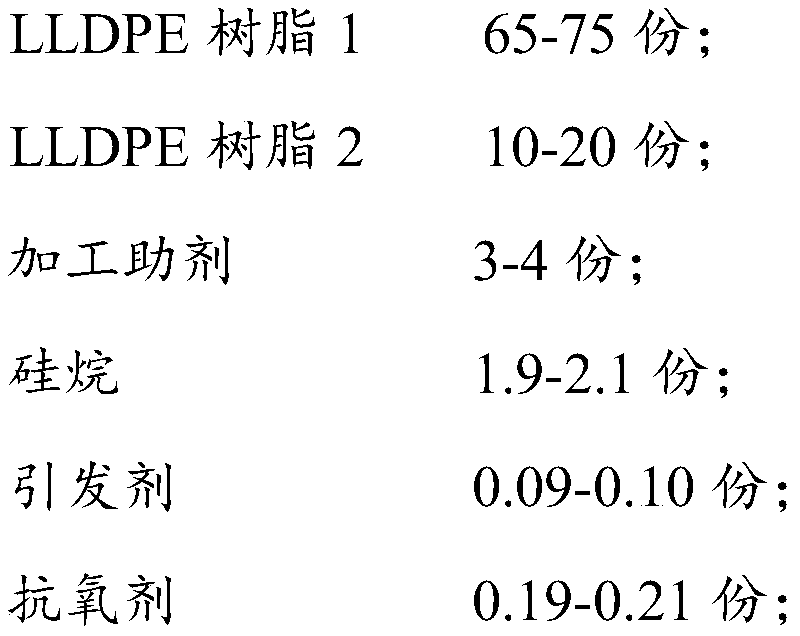

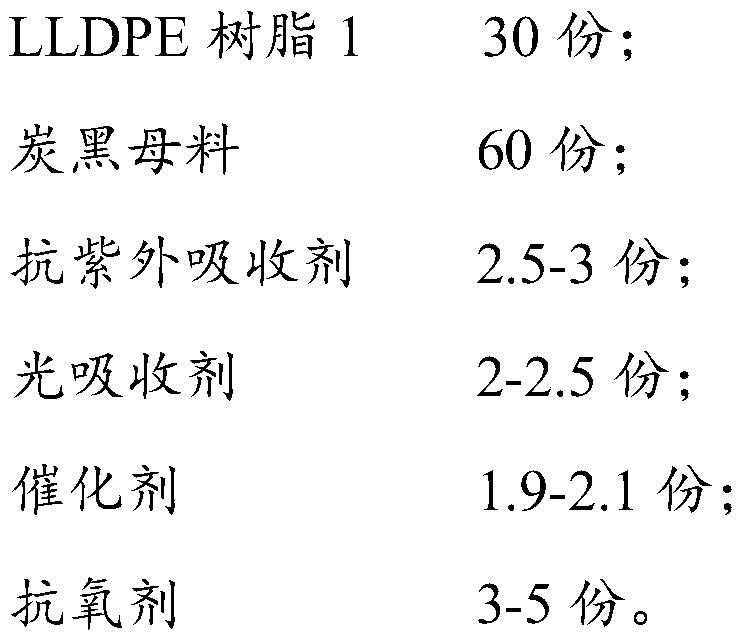

[0039] Prepare material A and material B according to the following formula (parts by weight):

[0040]

[0041]

[0042] Preparation of material A, dry the resin LLDPE DFDA-7042 and LLDPE M2320 at 90°C*2h according to the above ratio, then mix it with the processing aid FR-1, and then heat it to 50°C in the kneading pot Mix at high speed, add silane LT-171, initiator DCP, and antioxidant 1035 at the same time, mix at high speed for 3 minutes, and then feed into the twin-screw extruder. The temperature of each zone of the screw extruder during extrusion is as follows:

[0043] Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ Ⅵ Ⅶ Ⅷ Ⅸ nose 150 120 160 160 160 160 180 190 200 230

[0044] The extruded slivers are cut into pellets through the pull strips in the water tank, and then dried in a hot air dryer at 60°C for 1 hour, then dried in a cold air dryer for 1 hour, and then packed in a vacuum-pumped aluminum-plastic composite bag.

[0045] Preparation of material B: first dr...

Embodiment 2

[0049] Prepare material A and material B according to the following formula (parts by weight):

[0050]

[0051]

[0052] Preparation of material A, dry the resin LLDPE DFDA-7042 and LLDPE M2320 at 90°C*2h according to the above ratio, then mix it with the processing aid FR-1, and then heat it to 50°C in the kneading pot Mix at high speed, add silane LT-171, initiator DCP, and antioxidant 1035 at the same time, mix at high speed for 3 minutes, and then feed into the twin-screw extruder. The temperature of each zone of the screw extruder during extrusion is as follows:

[0053] Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ Ⅵ Ⅶ Ⅷ Ⅸ nose 150 120 160 160 160 160 180 190 200 230

[0054] The extruded slivers are cut into pellets through the pull strips in the water tank, and then dried in a hot air dryer at 60°C for 1 hour, then dried in a cold air dryer for 1 hour, and then packed in a vacuum-pumped aluminum-plastic composite bag.

[0055] Preparation of material B: first dry ...

Embodiment 3

[0059] Prepare material A and material B according to the following formula (parts by weight):

[0060]

[0061] Preparation of material A, dry the resin LLDPE DFDA-7042 and LLDPE M2320 at 90°C*2h according to the above ratio, then mix it with the processing aid FR-1, and then heat it to 50°C in the kneading pot Mix at high speed, add silane LT-171, initiator DCP, and antioxidant 1035 at the same time, mix at high speed for 3 minutes, and then feed into the twin-screw extruder. The temperature of each zone of the screw extruder during extrusion is as follows:

[0062] Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ Ⅵ Ⅶ Ⅷ Ⅸ nose 150 120 160 160 160 160 180 190 200 230

[0063] The extruded slivers are cut into pellets through the pull strips in the water tank, and then dried in a hot air dryer at 60°C for 1 hour, then dried in a cold air dryer for 1 hour, and then packed in a vacuum-pumped aluminum-plastic composite bag.

[0064] Preparation of material B: first dry the LLDPE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com