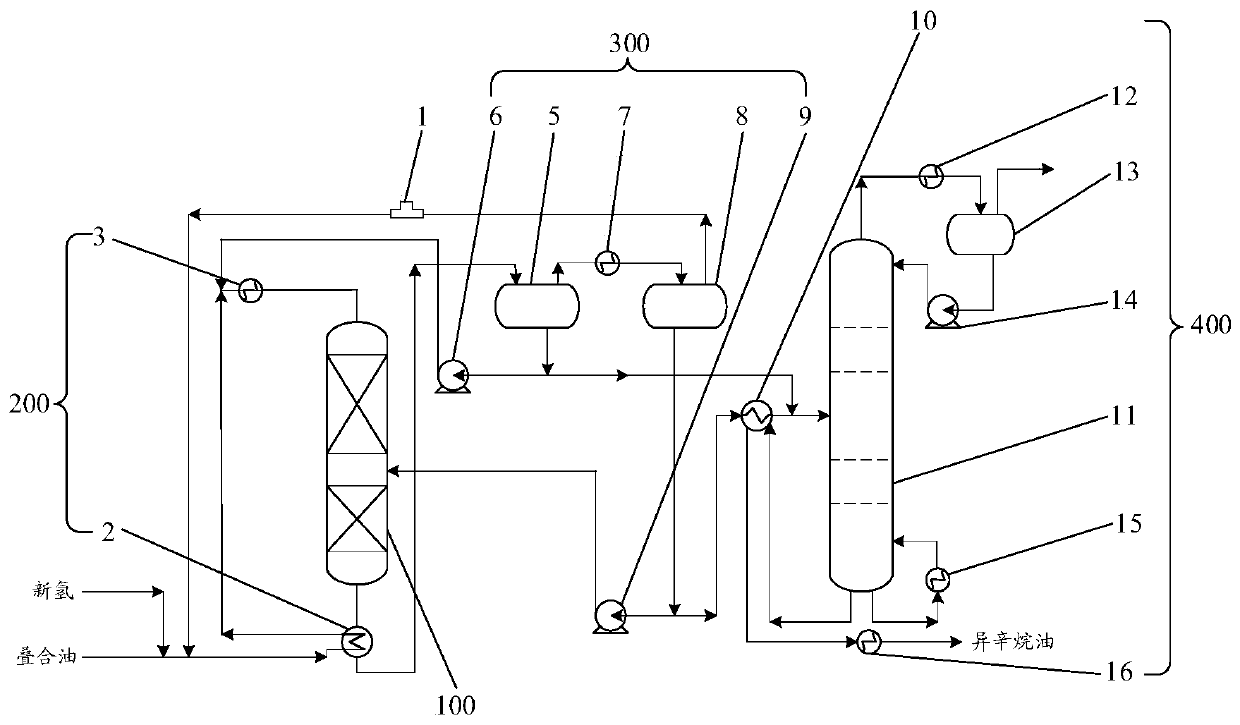

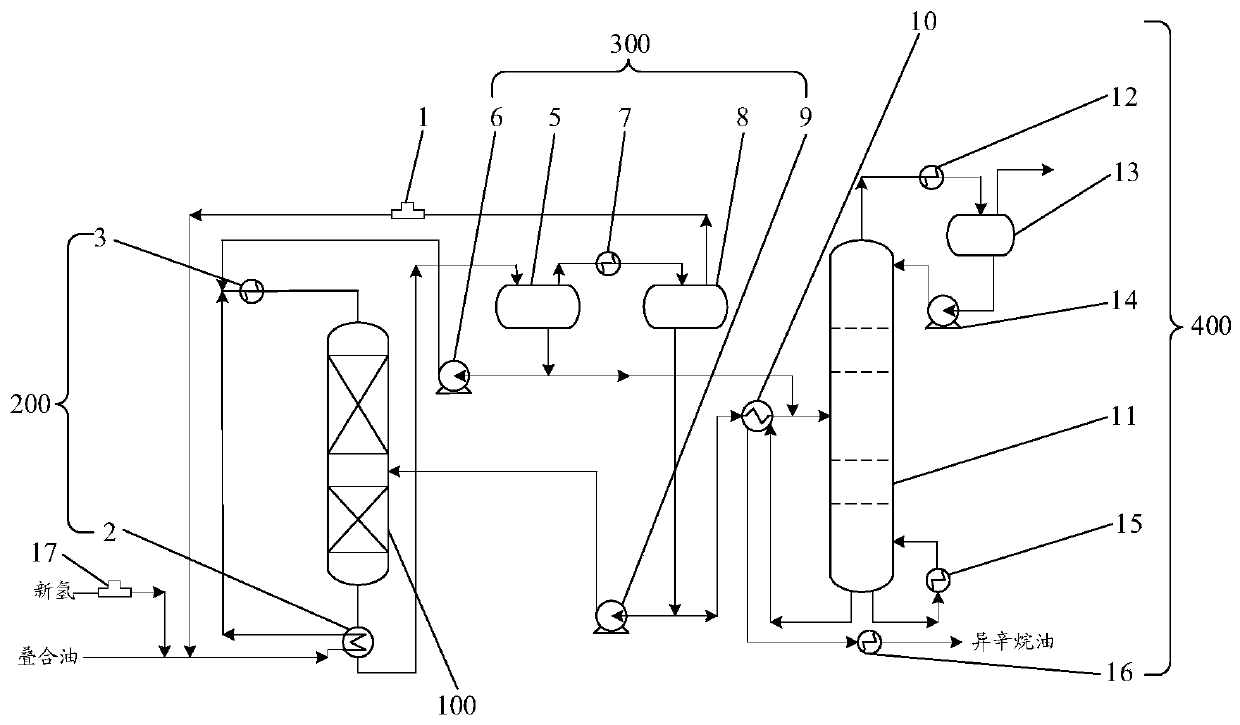

Superimposed oil hydrogenation system and method

A hydrogenation system and superimposed oil technology, which is applied in the fields of aromatics hydrorefining, petroleum industry, and hydrocarbon oil treatment, can solve problems such as complex structure and difficult maintenance, and achieve the effect of reducing energy consumption and olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

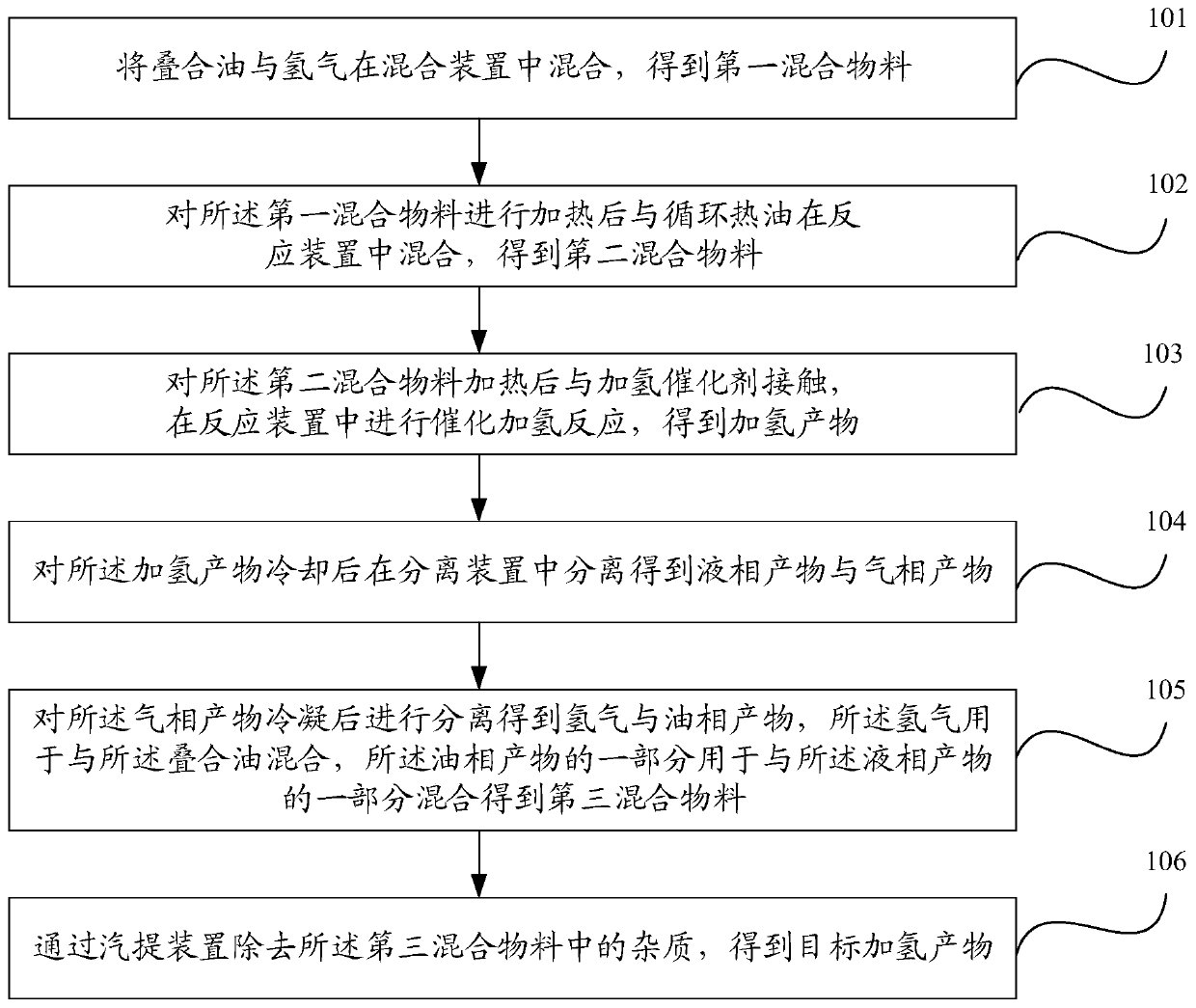

Method used

Image

Examples

Embodiment

[0124] The composition of superimposed oil produced by oligomerization of isobutene in a refinery is shown in Table 2. The flow rate of superimposed oil is 10.0 tons / hour, and the annual processing capacity is 84,000 tons.

[0125] Table 2 Composite oil composition

[0126] composition quality score C 8 Olefin

[0127] In order to produce high-quality clean gasoline blending component isooctane oil without olefins, the hydrogenation method and device provided in the examples of this application are used to carry out hydrogenation saturation of the superimposed oil. The main operating conditions are shown in Table 3.

[0128] Table 3 main operating conditions

[0129]

[0130]

[0131] After hydrogenation, the composition of the hydrogenated product, i.e. isooctane oil, is shown in Table 4.

[0132] Table 4 Composition of isooctane oil

[0133] composition mass percentage C 8 alkanes

[0134] It can be seen from Table 4 that after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com