Antique building steel cap block, bracket arm and center block combined structure mounting and construction method

A technology of combined structure and construction method, which is applied in the direction of building structure, construction, and building material processing, etc., can solve the problems of complicated construction technology of concrete structures, difficult control of the installation position of the rack, and small cross-sectional size of upgraded components, etc., to achieve reduction The effects of natural environment interference, easy promotion and use, and sufficient installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

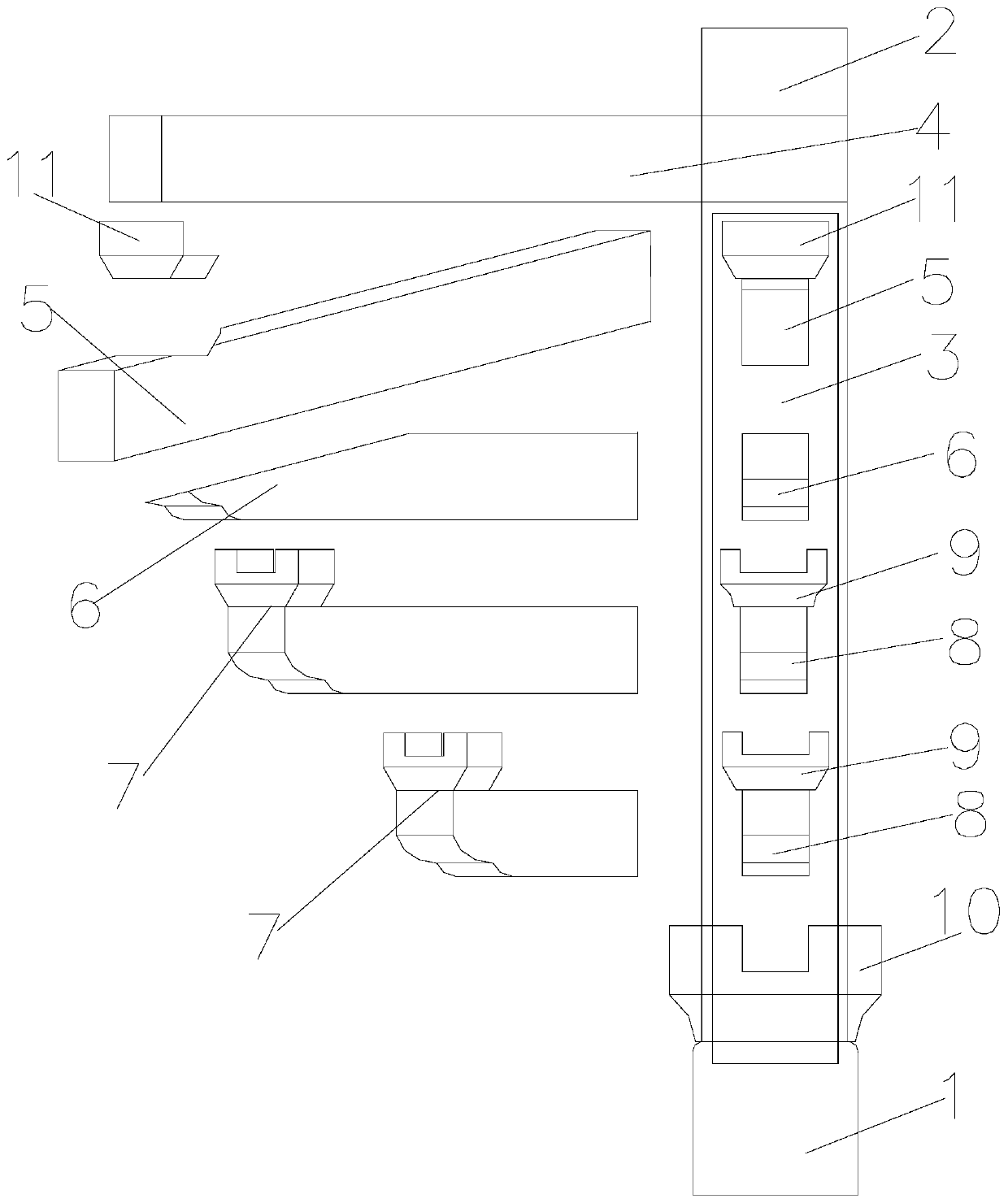

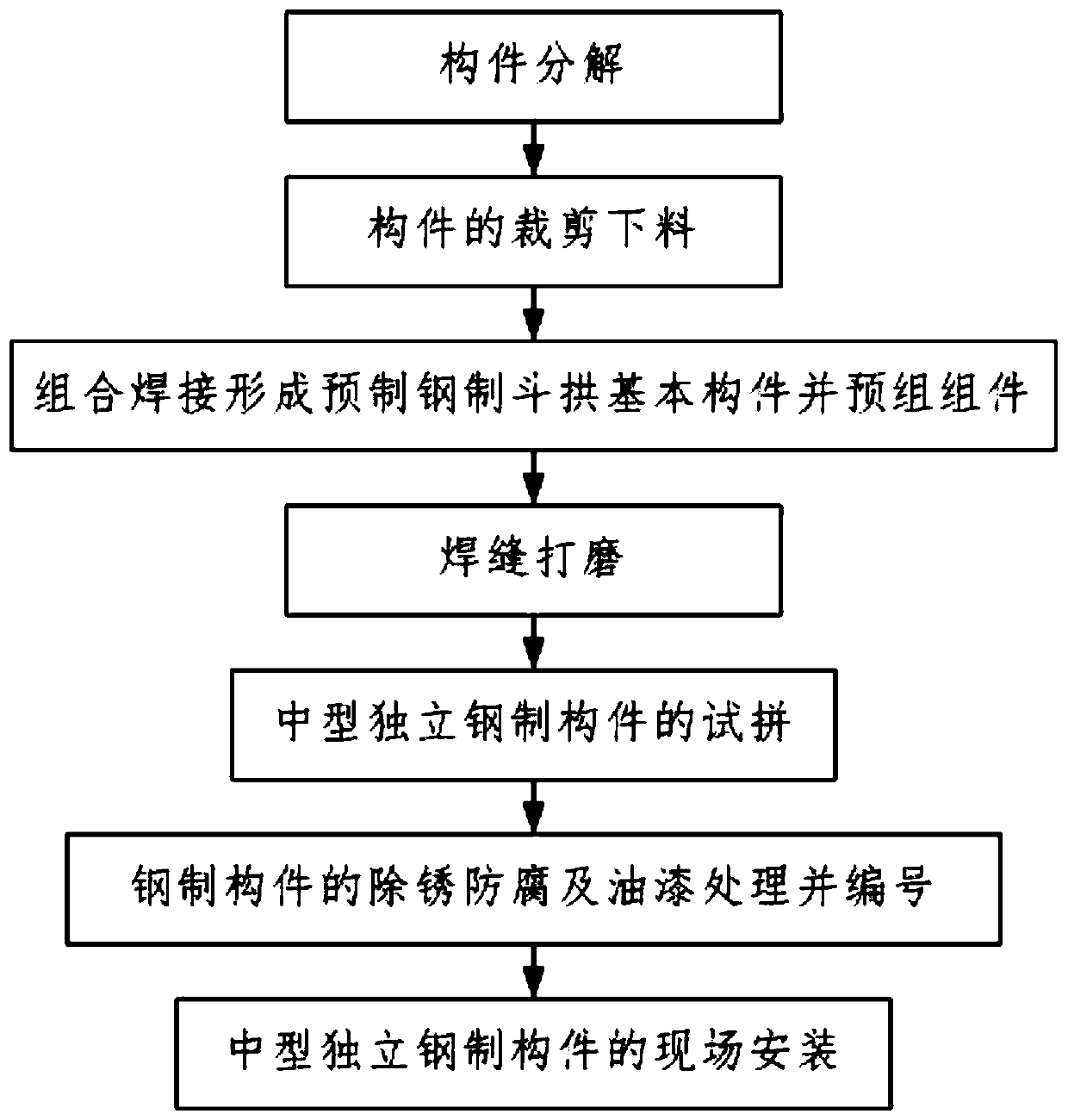

[0040] like figure 1 and figure 2 As shown, the installation and construction method of the antique building steel bucket arch rising composite structure of the present invention comprises the following steps:

[0041] Step 1. Component decomposition: According to the design drawings, use BIM modeling software to establish a BIM model of the combination of the antique building bucket arch components and the main column 2 and Fang 4, and display the form of the antique building bucket arch components in the form of three-dimensional graphics, and separate the components one by one. It is decomposed into angle beam components, high components, structural arch components, structural vertical components, seat bucket components and connecting vertical components;

[0042] The structural arch member includes a plurality of structural arch members having different lengths and dimensions;

[0043]A reserved steel plate 3 is reserved on the main body column 2, the main body column 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com