Solar heat absorber capable of being driven to rotate and translate through wind power and working method thereof

A solar heat absorber and wind power technology, applied in the field of solar thermal utilization, can solve the problems of unrealized movement along the axial direction, inability to solve energy flow, power grid consumption, etc., achieve simple processing and manufacturing, improve economic performance, and improve cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

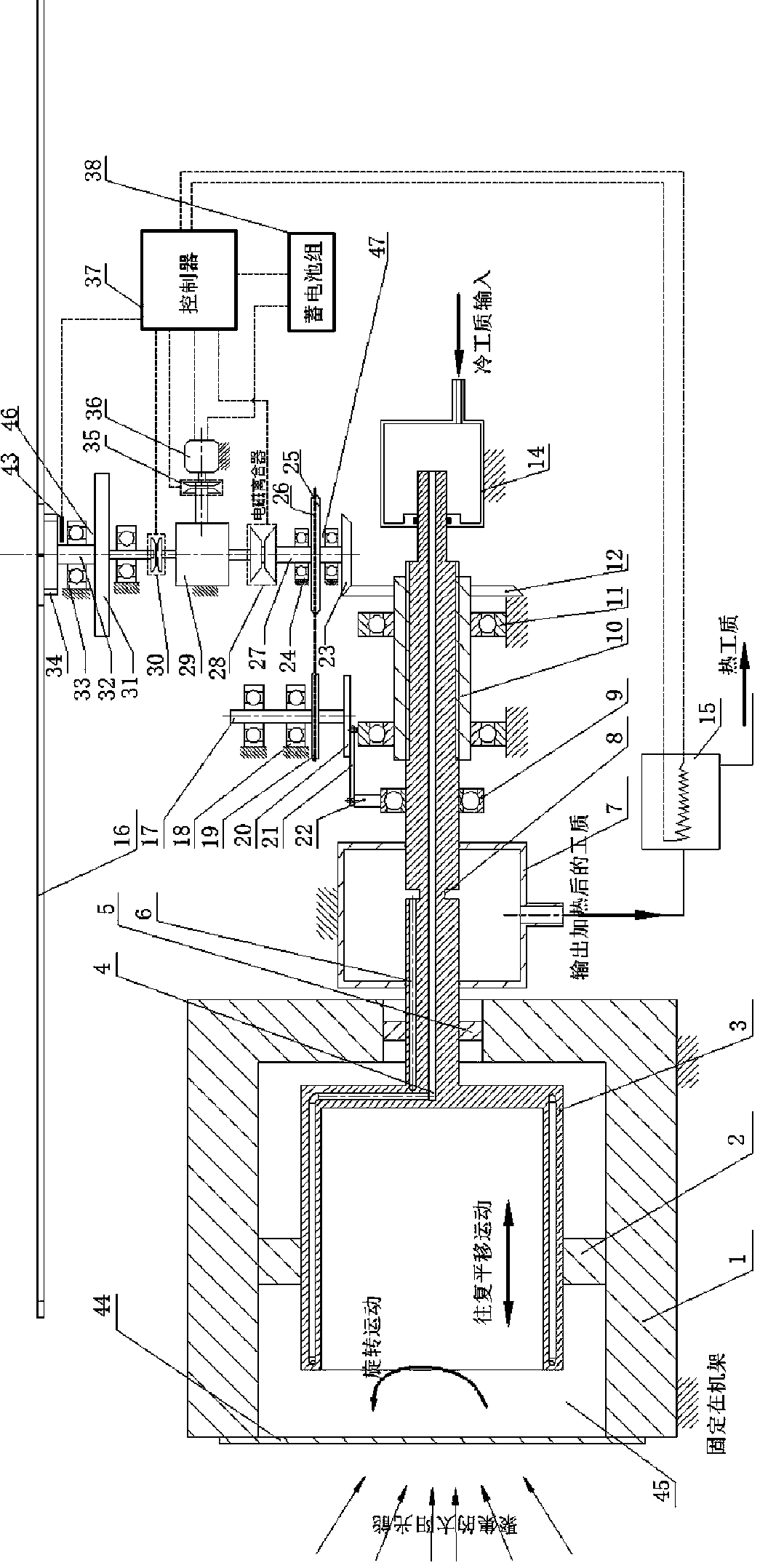

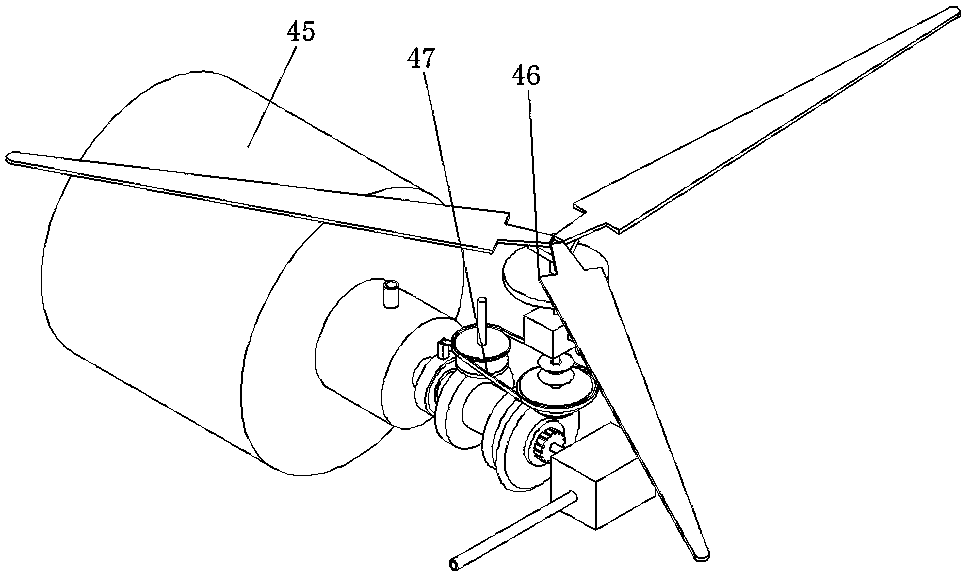

[0037] Figure 1-3 Shown is an embodiment of the present invention, which includes a cavity heat sink 45, a wind turbine unit 46, a transmission device 47, a DC motor 36, a battery pack 38, a controller 37 and a reheater 15.

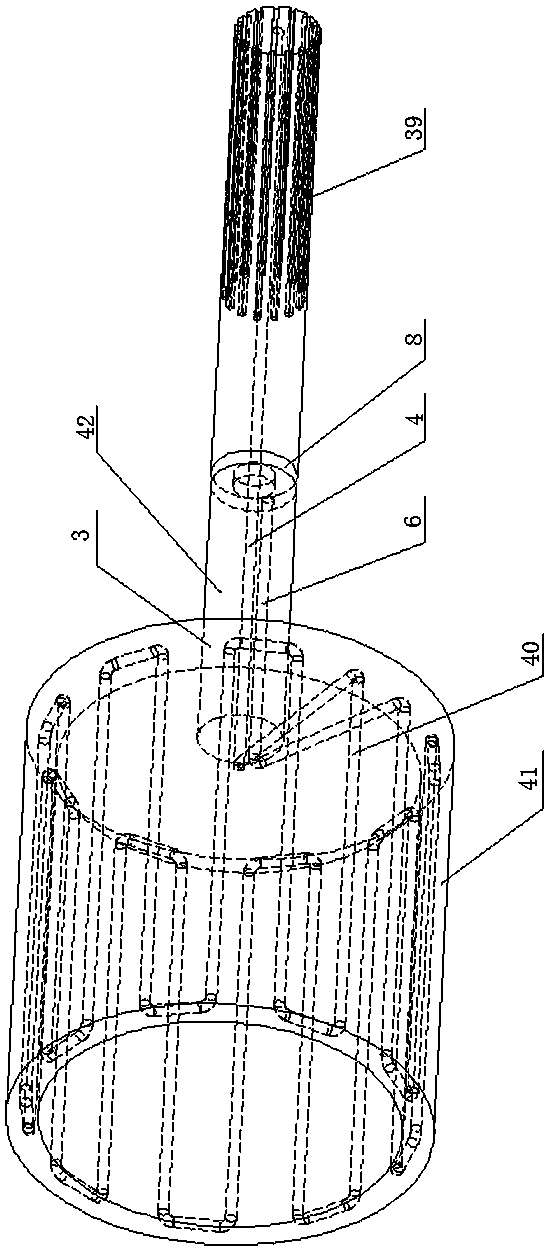

[0038] The cavity heat absorber 45 includes a heat preservation cavity 1, a heat absorption body 3, a hot working medium collection cavity 7 and a cold working medium collection cavity 14. The heat preservation cavity 1 has a cylindrical structure and is fixedly installed on the frame B. The open end of the heat preservation cavity 1 is provided with quartz glass to reduce the heat loss of the heat sink. The heat absorption body 3 includes a cylindrical heat absorption cavity 41 and a working fluid transport shaft 42. The working fluid transport shaft 42 is installed on the bottom plate of the heat absorption cavity 41 and is coaxial with the heat absorption cavity 41. The heat absorption cavity 41 is installed in the heat preservation cavity 1 through the...

Embodiment 2

[0044] Figure 4 Shown is another embodiment of the invention. It is similar to the structure of the first embodiment, except that the only difference lies in the working medium flow connection structure between the working medium transport shaft 42 and the cold working medium collection cavity 14 in the heat absorption body 3. The inlet of the working medium input channel 4 in the working medium transport shaft 42 is connected with the spherical hinge at one end of the flexible metal tube 13. The flexible metal tube 13 is a fluid working medium transmission element with spherical hinges at both ends. The ball hinge at the other end of the metal tube 13 is connected to the circular orifice of the cold working medium collection cavity 14, so as to realize the flow of the cold working medium collection cavity 14 to the working medium input flow channel 4 in the working medium transport shaft 42 and satisfy Rotation and translation movement conditions of the heat absorbing body 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com