Photoelectric image measuring instrument and measuring method for detecting verticality of large-size workpiece

A technology of image measurement and verticality, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of low measurement accuracy, time-consuming, labor-intensive, and complicated problems, and achieve high measurement efficiency, high detection accuracy, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

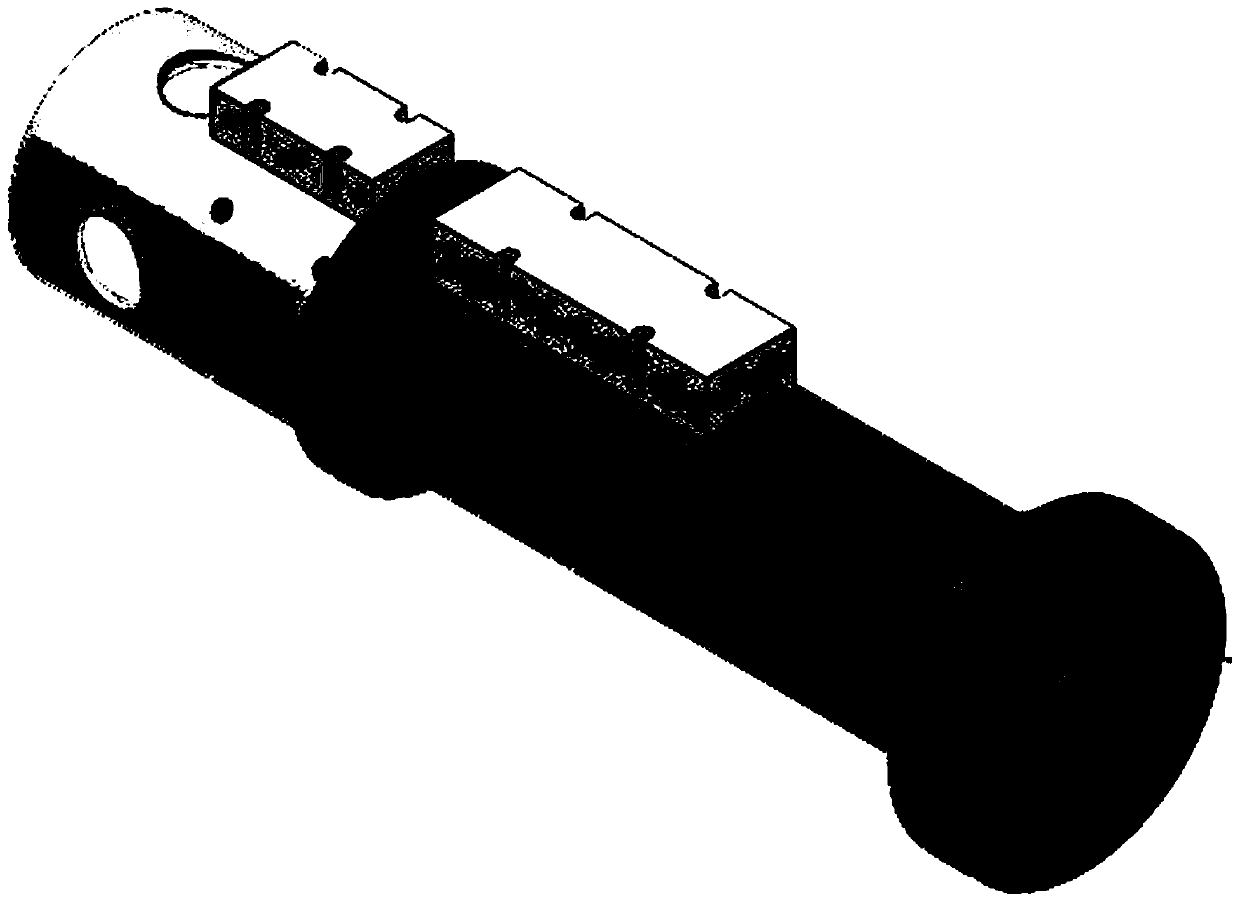

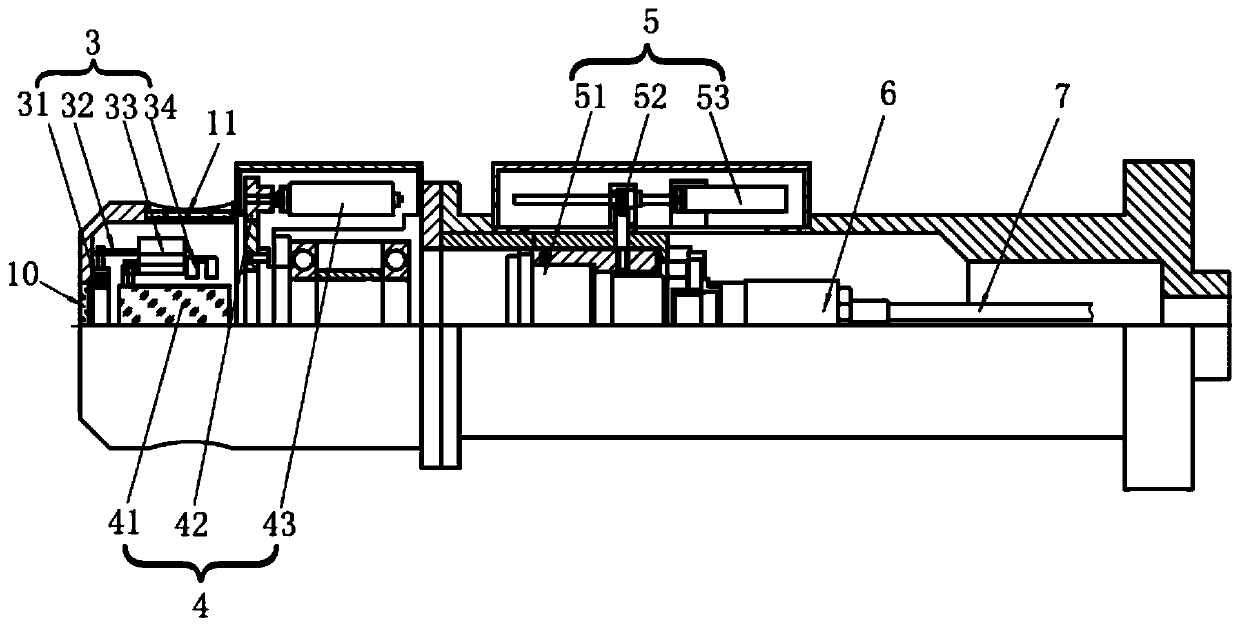

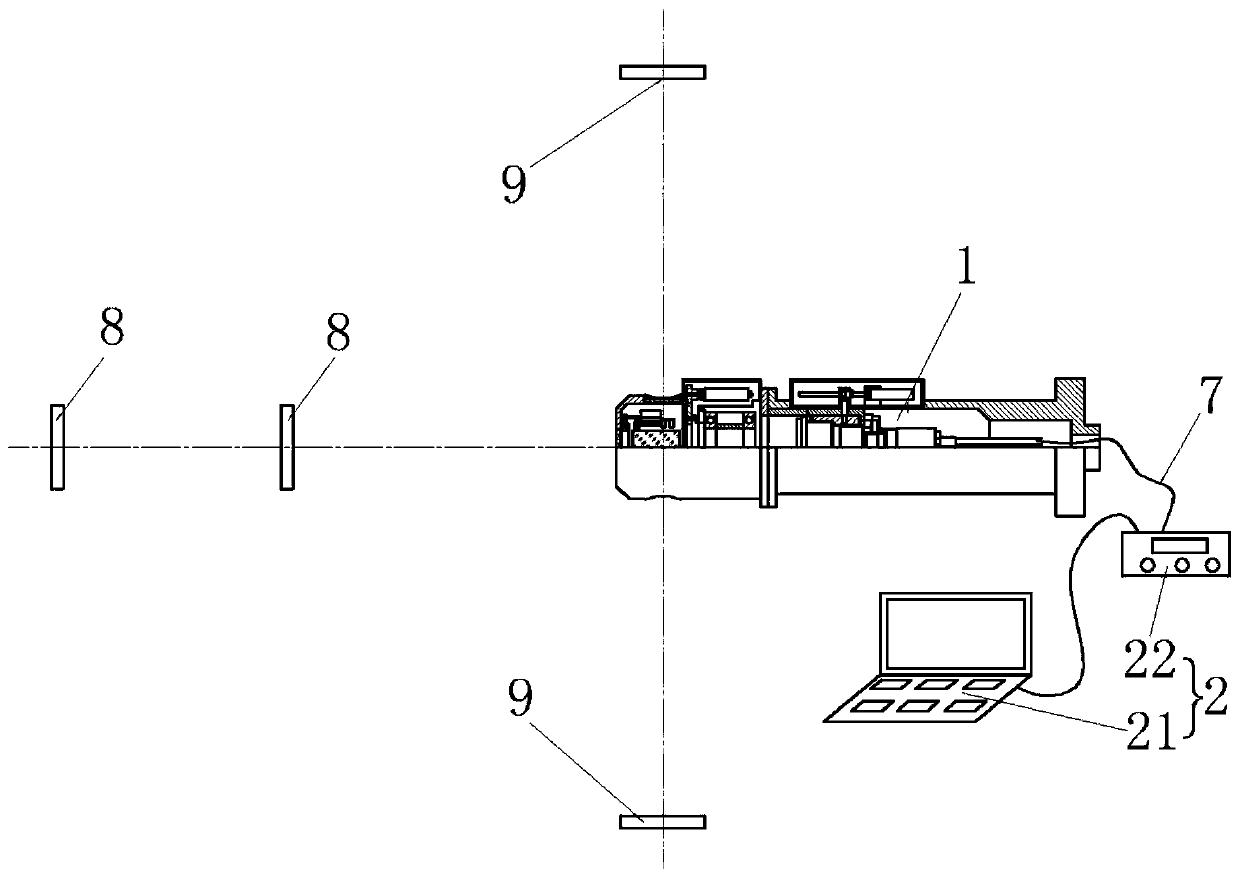

[0033] like Figure 1-Figure 2 As shown, the photoelectric image measuring instrument for detecting the verticality of a large-sized workpiece includes a measuring unit 1 and a control unit 2; hole; the housing is sequentially provided with an optical path switching unit 3, an optical peripheral scanning unit 4, an internal focusing optical imaging unit 5, and a CCD camera 6 from the front end to the rear end, wherein the housing corresponding to the optical path switching unit is uniform along the circumferential direction Set with four side windows. Therefore, this instrument can not only perform CCD imaging on the finite and infinity targets aimed at by the main optical system (i.e., the inner focusing optical imaging unit 5), but also can use the optical peripheral scanning unit 4 to scan the target perpendicular to the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com