IGBT junction temperature estimation method based on IGBT thermoelectric coupling model

A thermoelectric coupling and thermal coupling technology, which is applied in the electric power field, can solve the problems of difficult to measure the temperature rise curve and inapplicable thermal parameters, and achieves the effect of fast calculation speed, simple operation and simplified solution process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] combined with Figure 1-18 , the present invention will be further described.

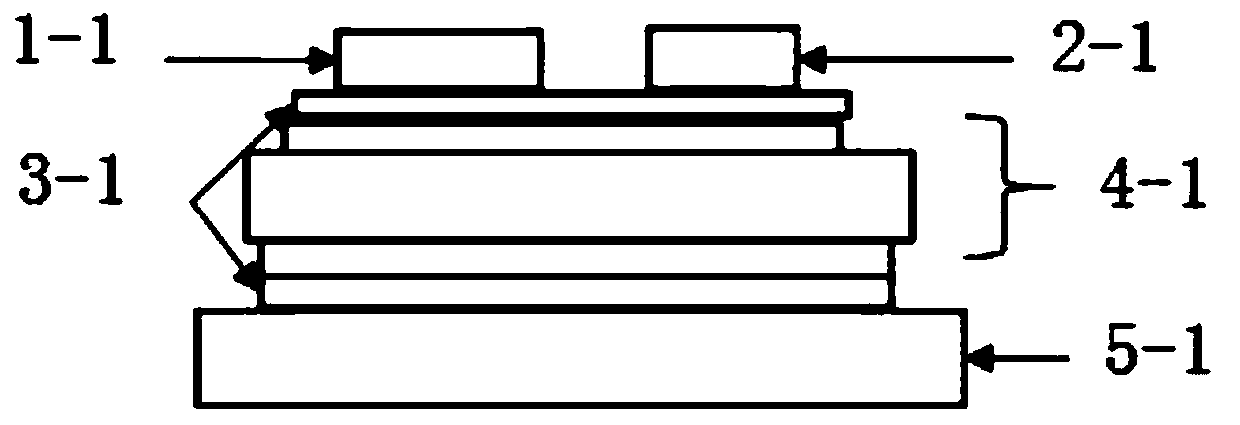

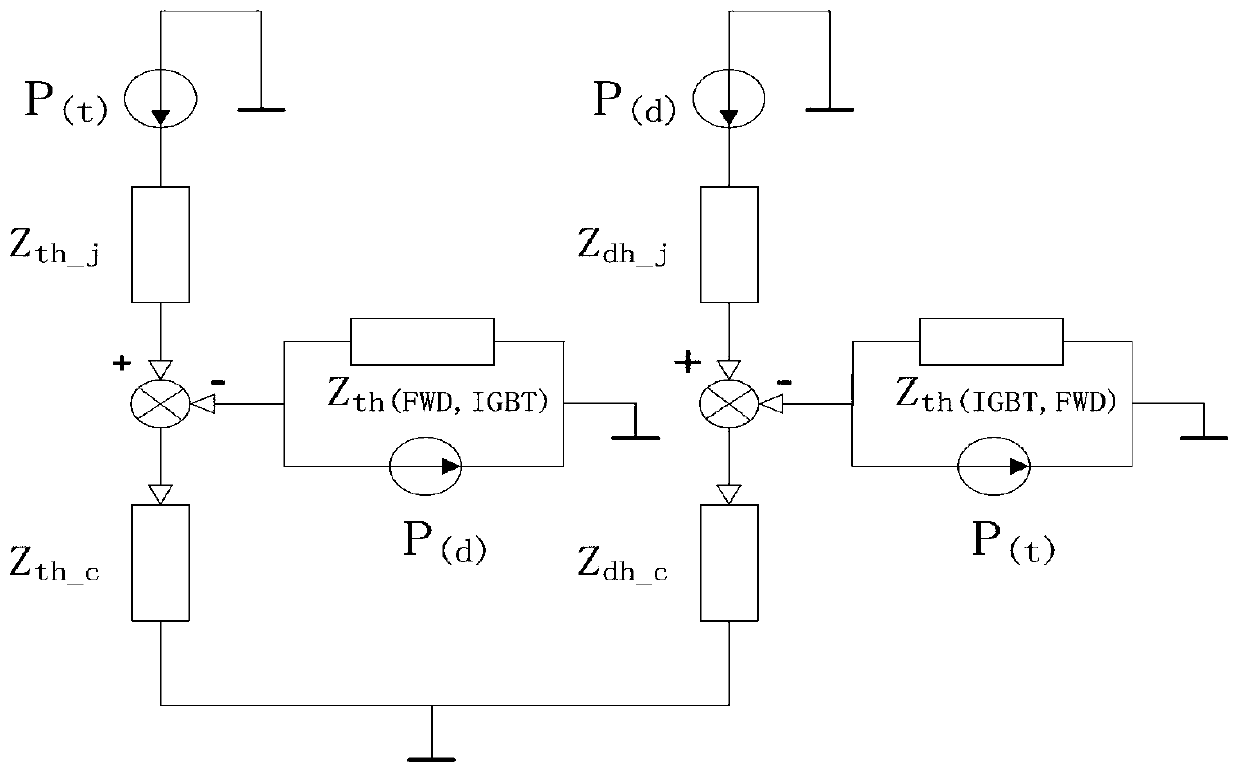

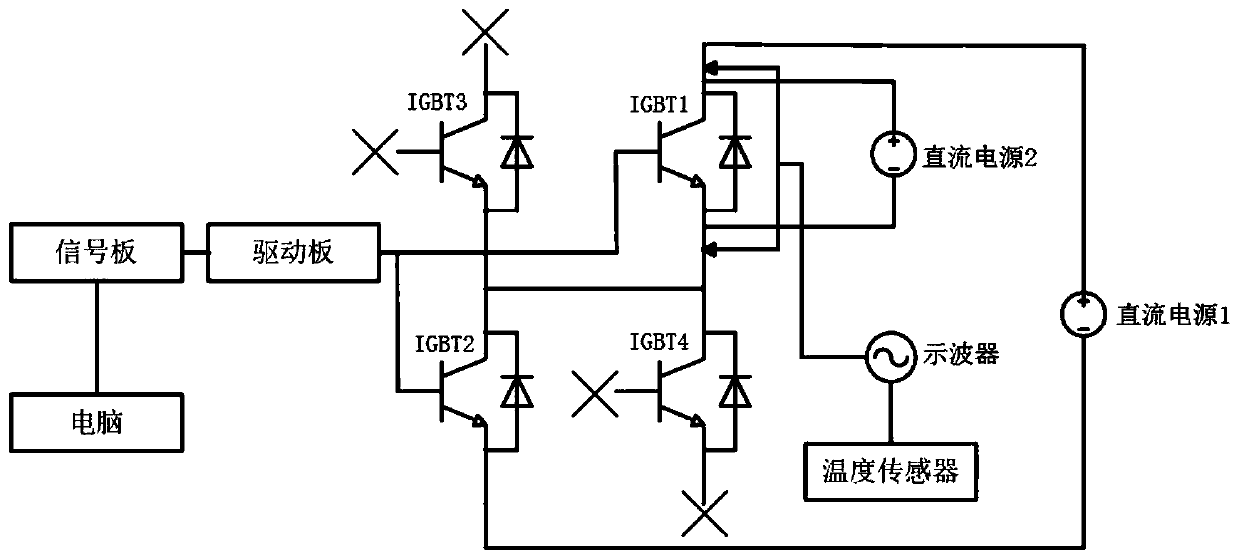

[0043] figure 1 is the heat transfer route of the IGBT, wherein the chip 1-1, the diode 2-1, the soldering layer 3-1, the DCB board 4-1, and the base plate 5-1 are copper base plates. Considering the two-dimensional improved model established by the interaction between the reverse diode and the IGBT, a two-dimensional coupling thermal resistance network model is established. Because the one-dimensional thermal resistance network model has certain limitations, a two-dimensional coupled thermal resistance network model is established, such as figure 2 As shown, where Pt: IGBT power loss, Pd: anti-parallel diode power loss, Zth-j: IGBT junction-case thermal impedance, Zth-c: case-to-ambient thermal impedance below the IGBT, Zth(FWD,IGBT): IGBT Relative to the diode thermal impedance, Zdh-j: junction-to-case thermal impedance of the diode, Zdh-c: case-to-ambient thermal impedance below the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com