Super junction and manufacturing method thereof

A manufacturing method and super junction technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of process instability, easy damage, device failure, etc., to improve the breakdown voltage and the uniformity of the breakdown voltage in the plane performance, fast production rate, and the effect of improving product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

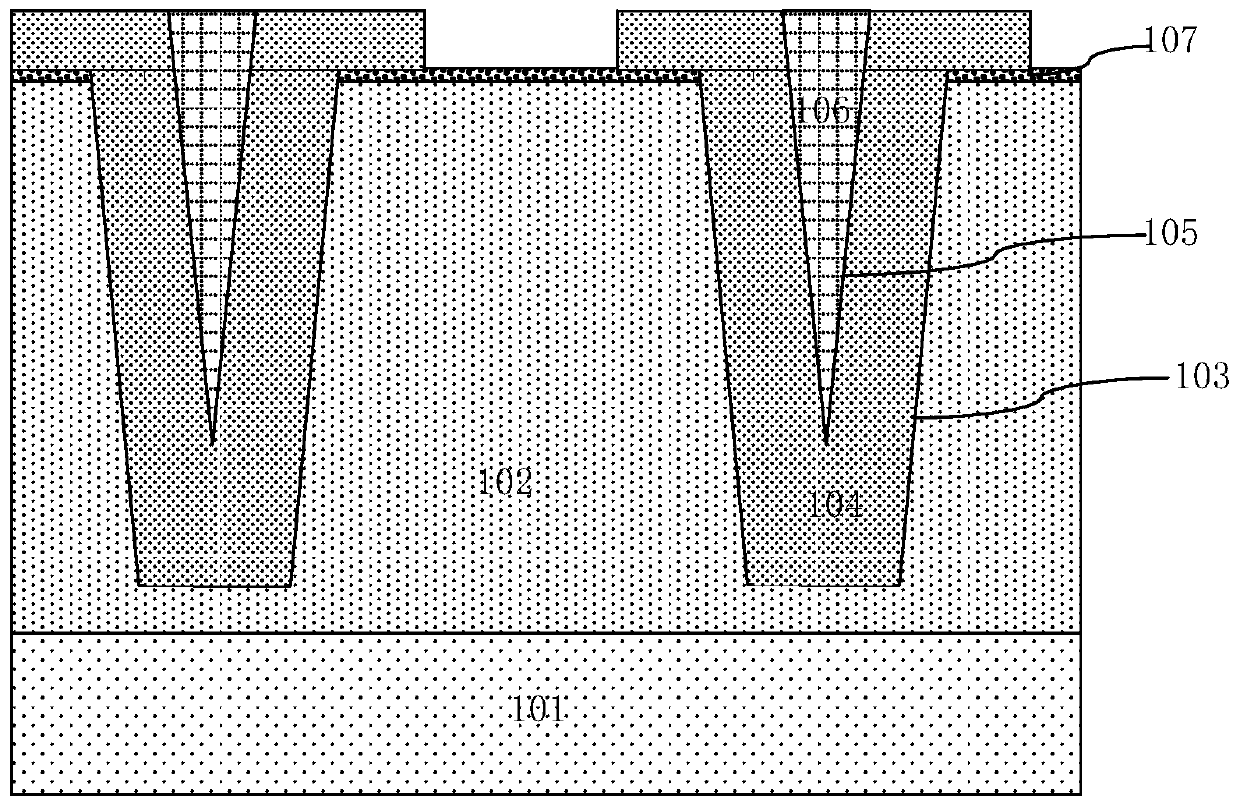

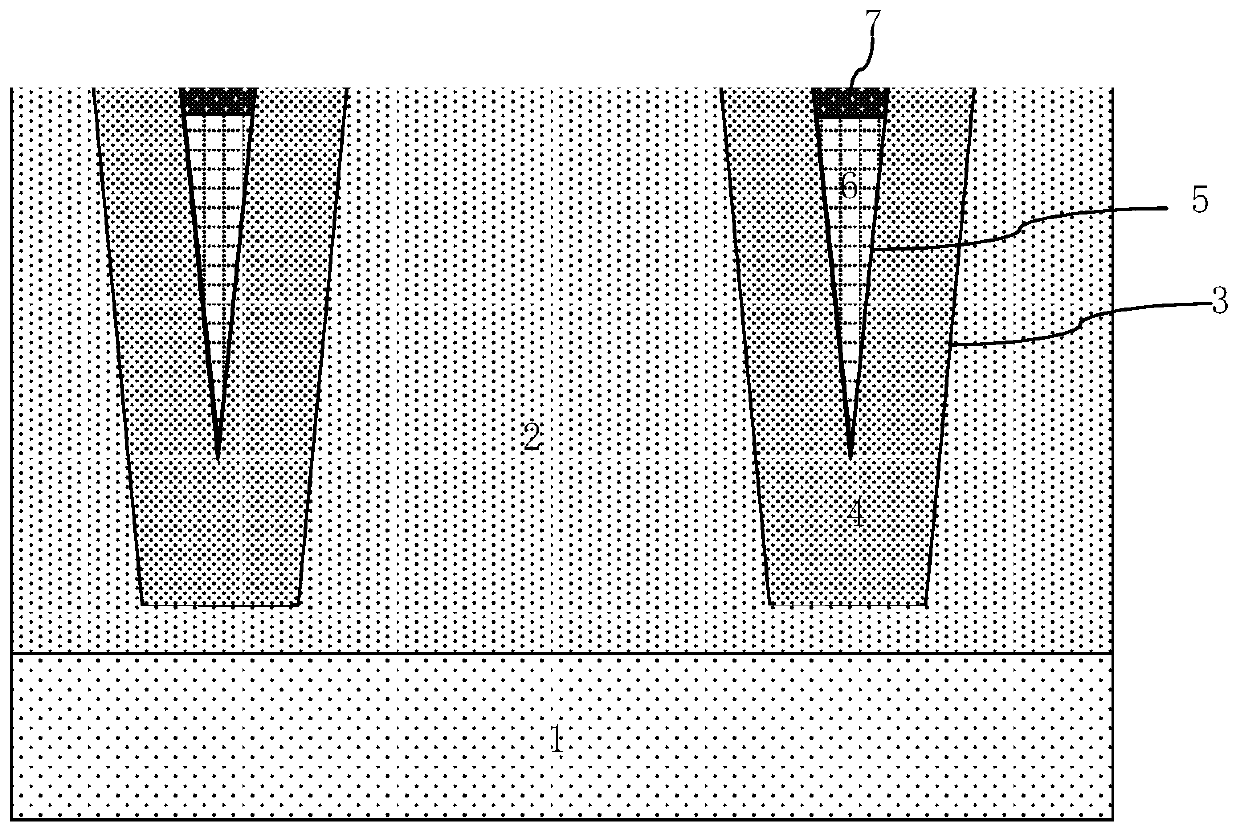

[0052] Such as figure 2 Shown is a schematic diagram of the device structure of the super junction of the embodiment of the present invention; the super junction of the embodiment of the present invention includes:

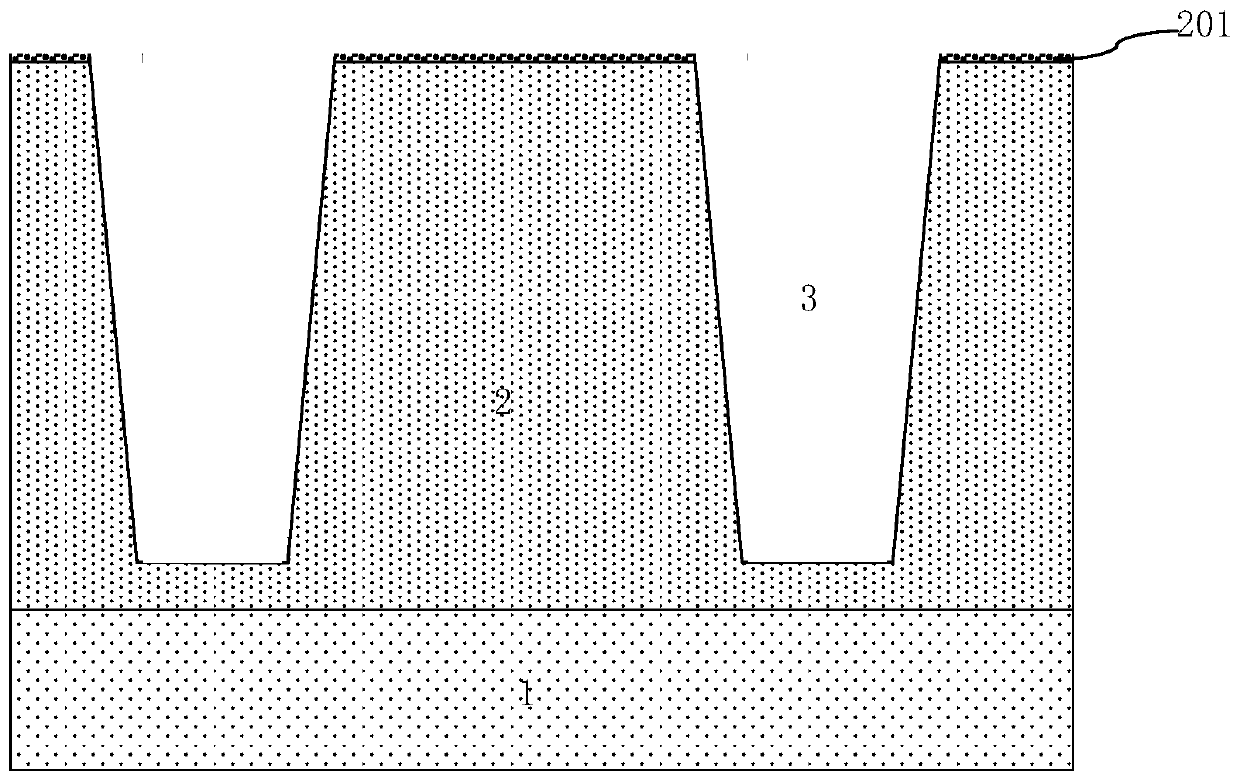

[0053] A plurality of trenches 3 are formed in the first epitaxial layer 2 of the first conductivity type, and the first epitaxial layer 2 is formed on the surface of the semiconductor substrate 1 .

[0054] A second epitaxial layer 4 of the second conductivity type is formed on the bottom surface and side surfaces of the trench 3, the second epitaxial layer 4 does not completely fill the trench 3 and surrounds the trench 3 V-shaped opening 5.

[0055] The V-shaped opening 5 is filled with a first dielectric layer 6 and a non-doped semiconductor layer 7, the non-doped semiconductor layer 7 is located on the top of the first dielectric layer 6, and the non-doped semiconductor layer 7 and the second epitaxial layer 4 enclose the first dielectric layer 6 inside to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com