High-voltage electric power test vehicle networking platform

A high-voltage test and high-voltage power technology, applied to electrical components, closed-circuit television systems, data exchange networks, etc., can solve problems such as time-consuming and labor-intensive, increased labor costs, and uneven handwriting clarity, so as to improve safety and reliability Safety, improved safety and user-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

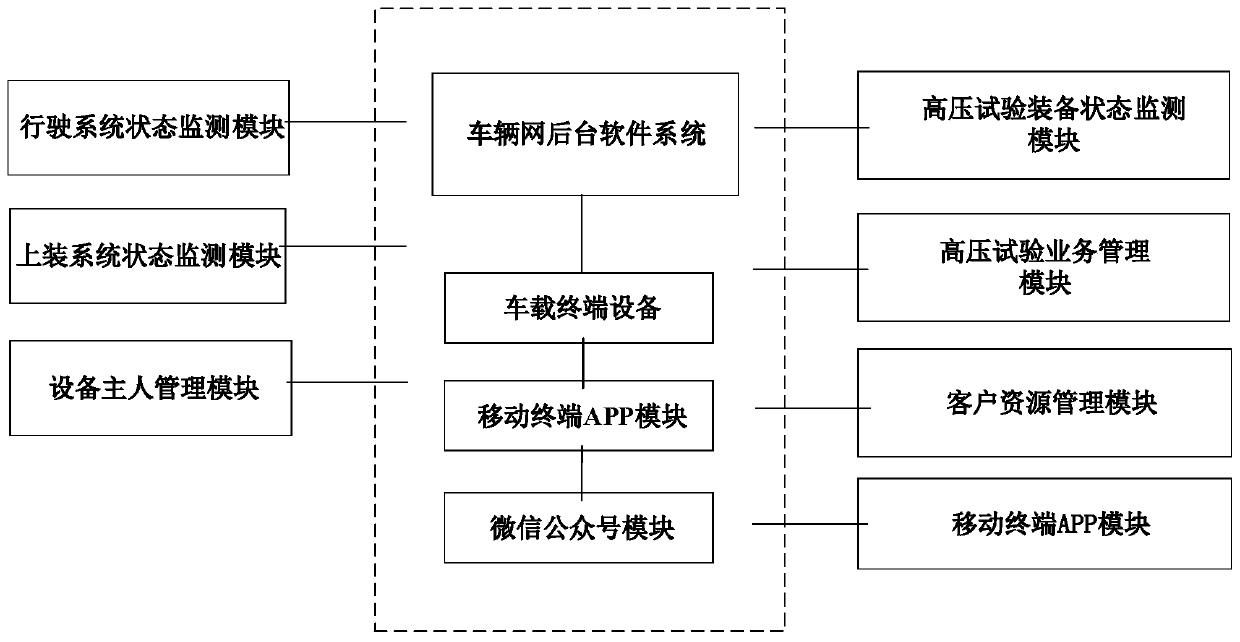

[0040] like figure 1 , 2, a high-voltage electric test vehicle vehicle networking platform, including driving system status monitoring module, bodywork system status monitoring module, high-voltage test equipment status monitoring module, high-voltage test business management module, customer resource management module, equipment owner management module, 4G / 5G Internet of Things communication module, Internet of Vehicles background software system, vehicle-mounted terminal equipment, mobile terminal APP module and WeChat official account module; driving system status monitoring module, used for driving system status monitoring; bodywork system status monitoring module, used for bodywork system Condition monitoring; the high-voltage test equipment condition monitoring module is used to monitor the high-voltage test process. The high-voltage test process includes locking the car, extending the legs, recovering the bracket, judging whether the test conditions are met, boosting, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com