Gas production and supercharging device

A technology of supercharging device and heating device, which is applied in jet propulsion device, gas turbine device, rocket engine device, etc., can solve the problems of low use efficiency of high-pressure gas, complicated pipeline, large occupied volume, etc., to reduce heating demand, The effect of increasing gas production and eliminating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

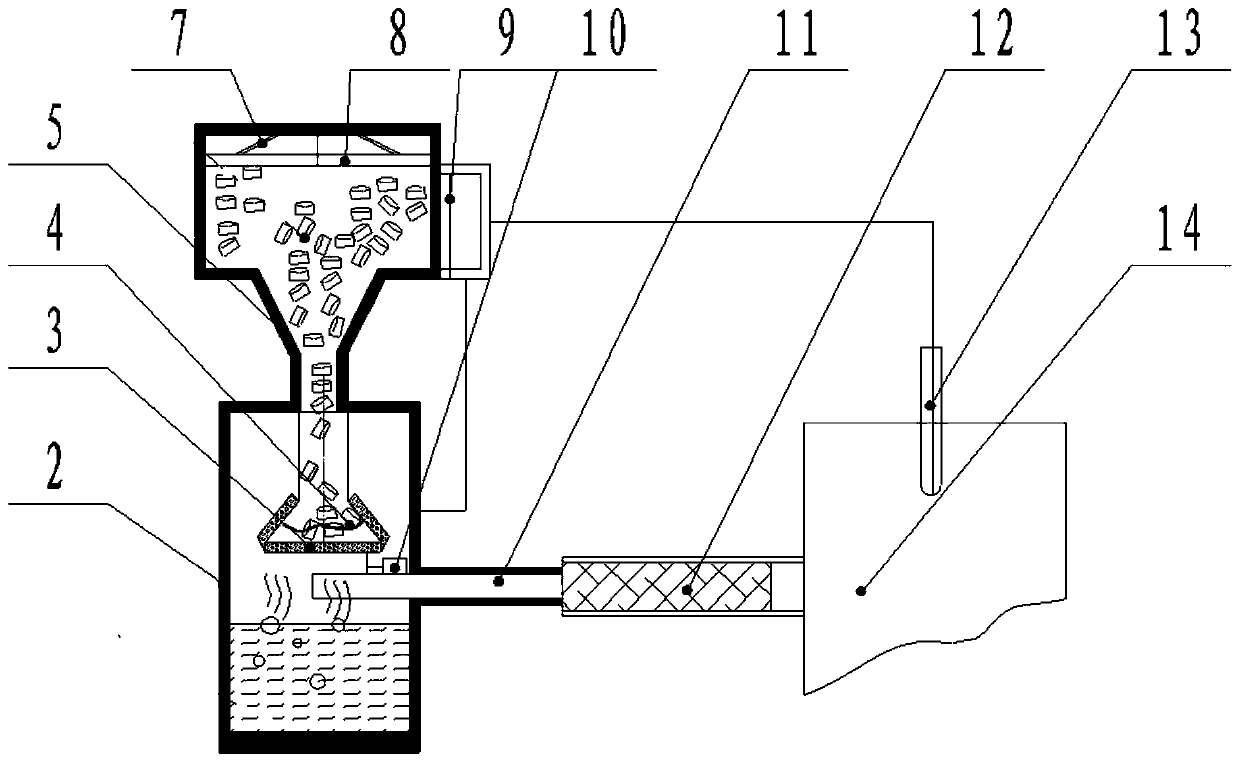

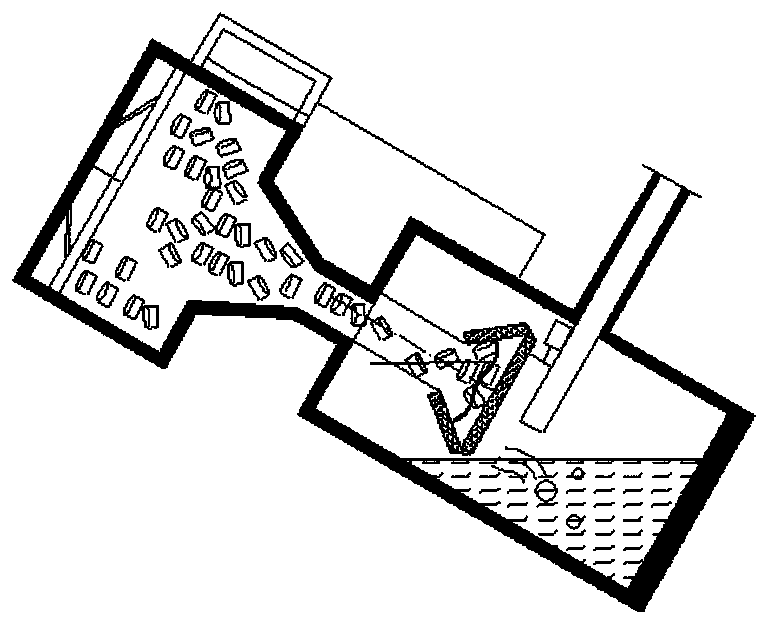

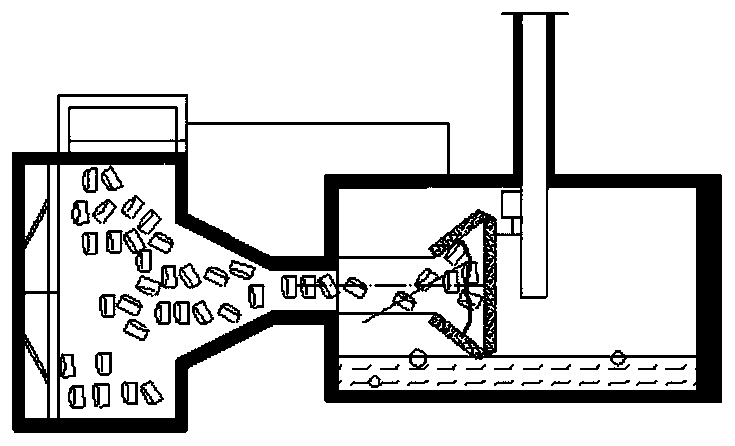

[0037] A gas production pressurization device, including a gas production module, a push module, a control module, and an adaptive attitude structure design, the specific structure of which is as follows figure 1 Shown:

[0038]Gas production module: a sealed tank body 2 with a heating device 4, a screen 3, a sodium azide gas generating agent, a vibration motor 10 and a certain amount of water; the tank body is divided into upper and lower parts, and the upper part is a feeding box 5 , is used to contain the gas generating agent, the lower end is a gas storage tank, which is used to store the reaction gas, and a certain amount of water is placed for the sodium azide heating product sodium to react again; the lower end neck of the funnel-shaped feeding box 5 extends into the storage tank In the gas box, the heating device 4, the screen 3 and the vibrating motor 10 are all arranged at the neck port of the lower end of the charging box 5, so that the gas generating agent is heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com