Efficient EGR introducing and mixing system

A mixing system and EGR valve technology, applied in the direction of charging system, fuel injection control, engine components, etc., can solve the problems of EGR mixing unevenness, high EGR flow resistance, engine efficiency decline, etc., to achieve simple interface and realize air intake Resistance, thermal efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

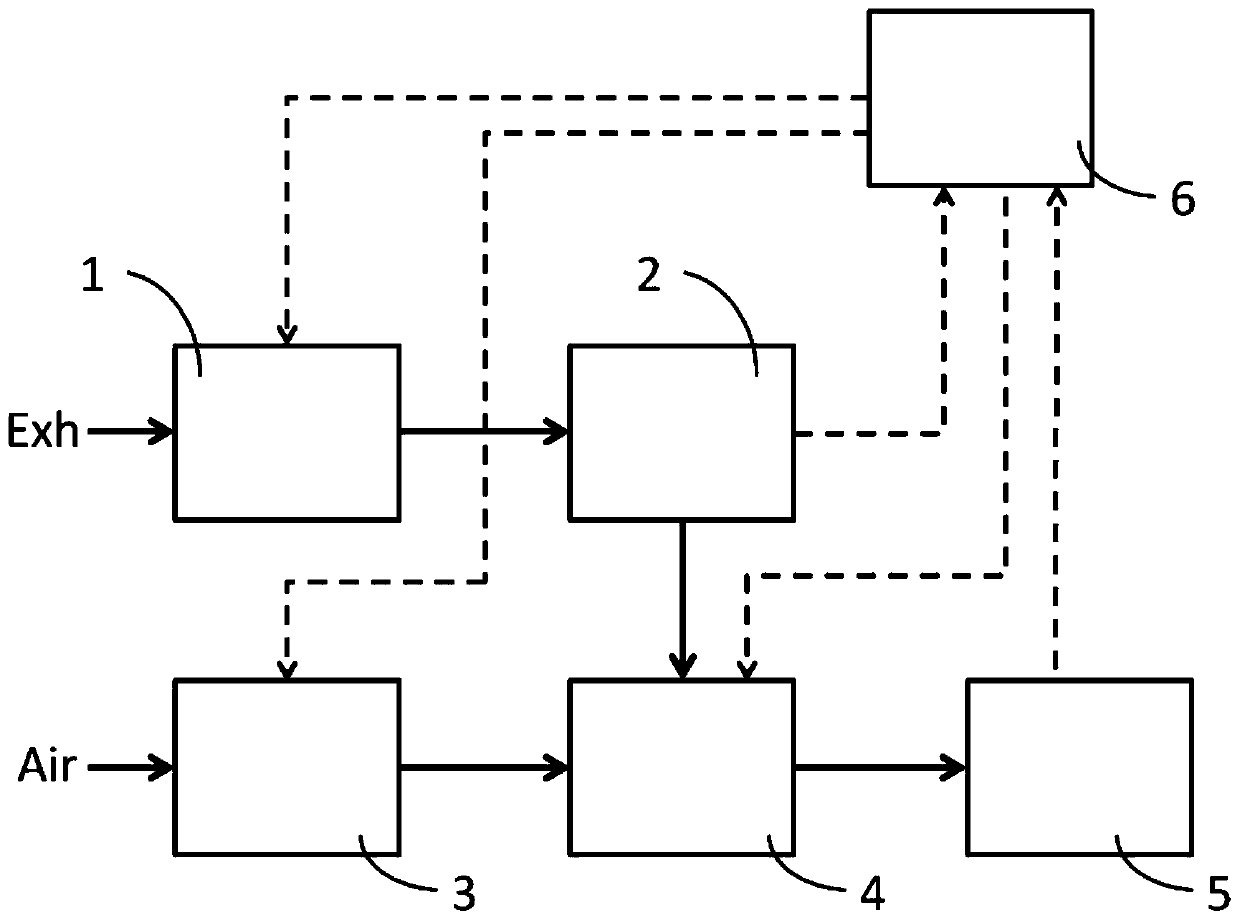

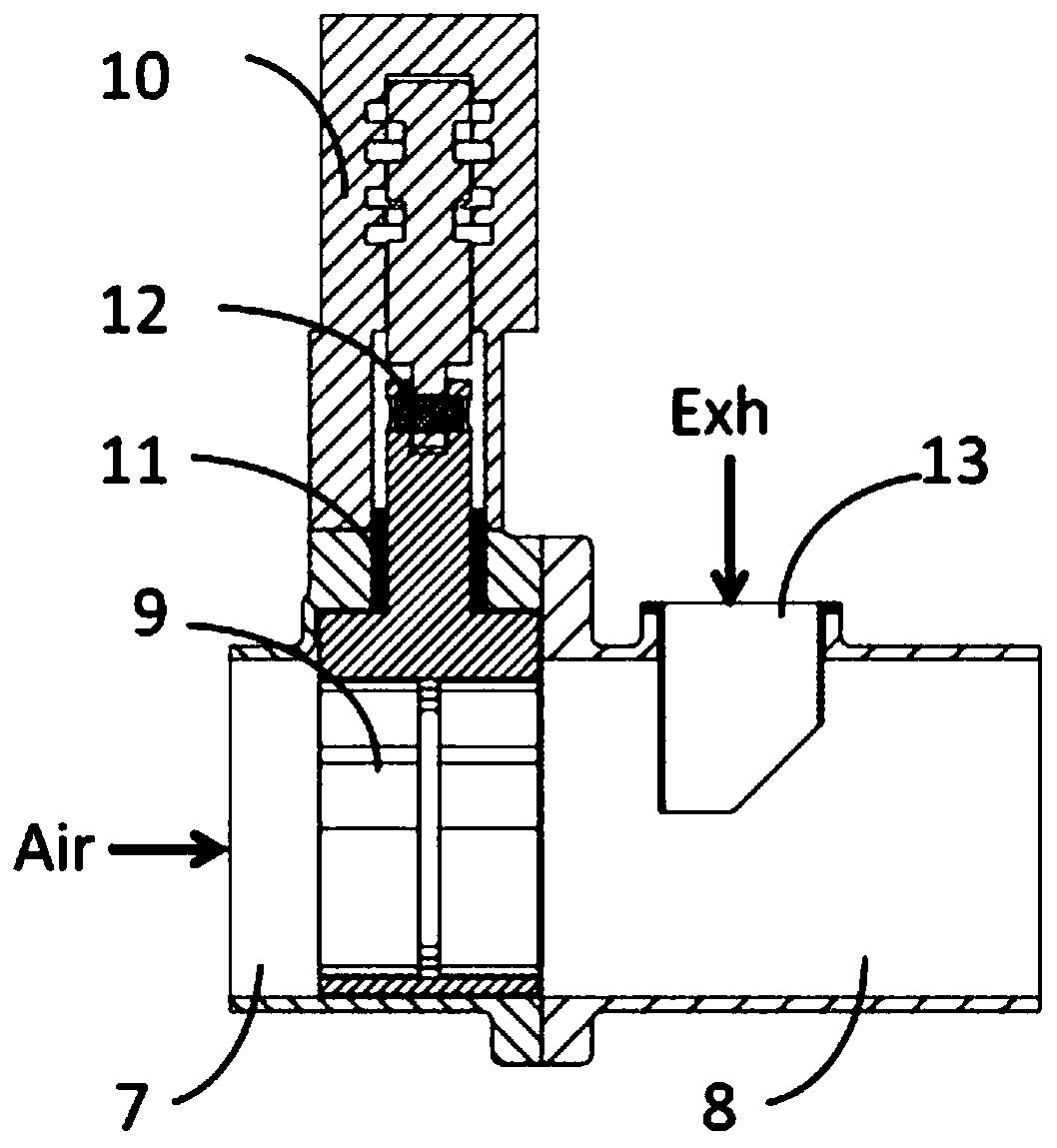

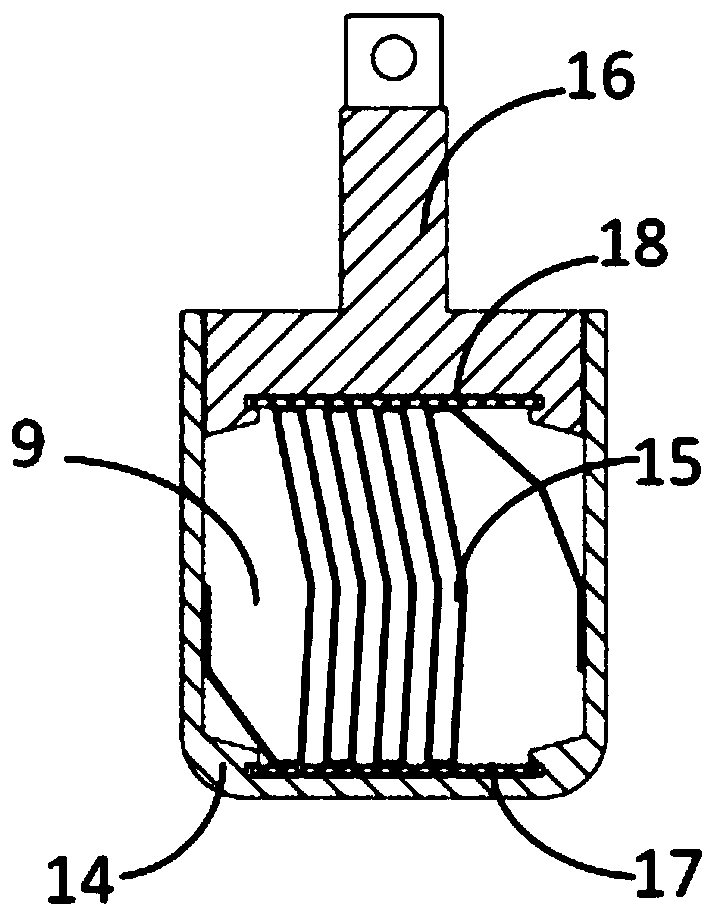

[0016] refer to figure 1 , a high-efficiency EGR introduction hybrid system, including EGR valve 1, venturi tube sensor 2, intake throttle valve 3, mixer 4, intake air temperature and pressure sensor 5, ECU6 and other components.

[0017] The EGR valve 1 is controlled by the ECU6, and its main function is to control the flow of exhaust gas. The main function of Wen Qiuli tube sensor 2 is to measure the flow rate of exhaust gas and send the data to ECU6 at the same time. The intake throttle valve 3 is controlled by the ECU6, and its main function is to control the air flow. Mixer 4 is controlled by ECU6, and its main function is to mix air and exhaust gas. The main function of the intake air temperature and pressure sensor 5 is to measure the pressure and temperature of the mixture, and send the data to the ECU 6 at the same time. ECU6 is the engine control unit, its function is to receive the signals from venturi tube sensor 2 and intake air temperature and pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com